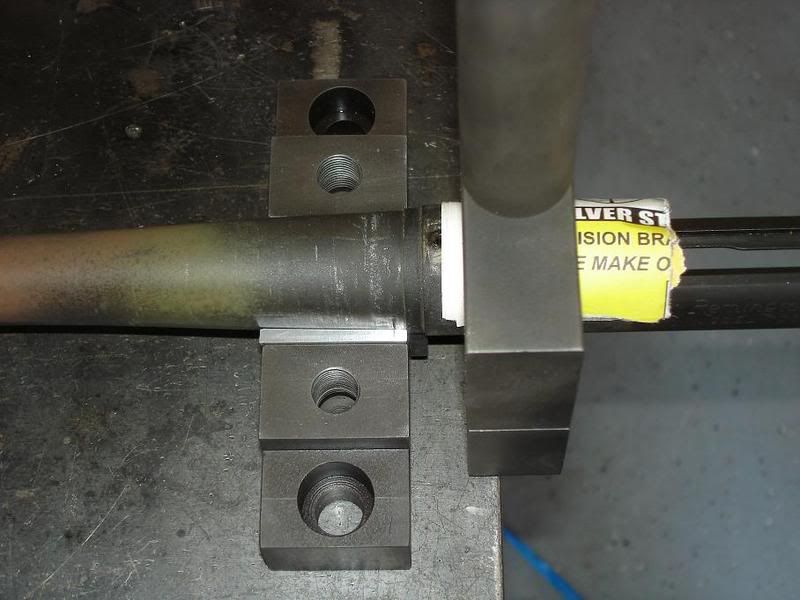

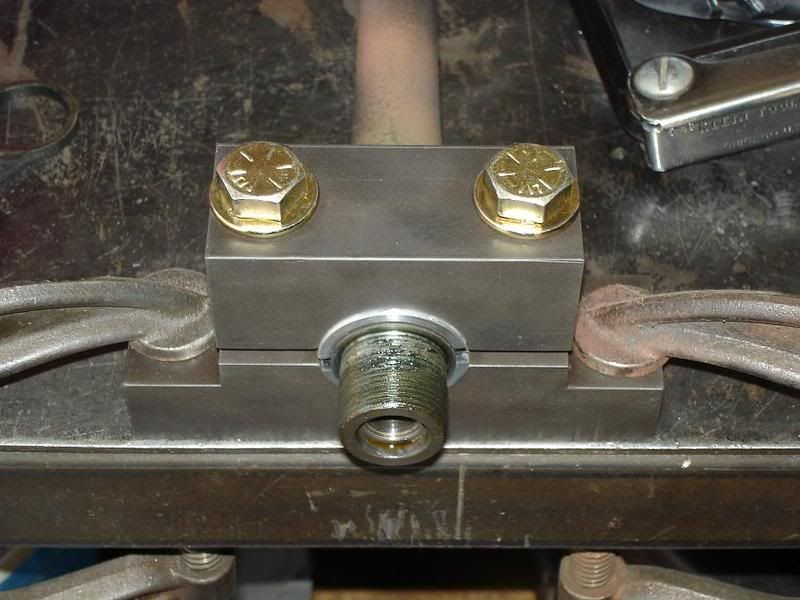

All, and I mean ALL of the Remington barrels I have removed, and it has been literally hundreds, required heat to break the thread locker grip on the threads. It is also necessary to have a well fitted action wrench and a well fitted barrel bushing in the barrel vise. I use a standard propane torch for heat which will not generate enough heat to alter the steel composition or ruin the blueing. I heat the action while in the barrel vise and before I add the action wrench. I do not advocate the use of an in the bolt bore type of action wrench; some are not made to support the action and may cause it to bend. My barrel vise uses tapered aluminum bushings made to fit the barrel and a 4" square block of steel, split and bored for the bushings, and four 1/2"-20 allen head cap screws for pressure against the barrel. It has never failed to break the bond between barrel and action