Push a lead slug through it. If one end is looser than the other, put that at the breech.

And don't be surprised if you taper it, and it's a button rifled barrel, that it reverses itself.

I'm sorry... I normally try to stay out of this type of thread because I always manage to kick someone's sacred cow... But I have to kick this cow none the less..

"don't be surprised if you taper it, and it's a button rifled barrel, that it reverses itself"

WTF!!! This myth has got to be one of the most absurd things in in the industry and completely ignores HOW barrels are made.

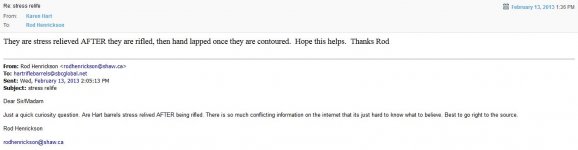

Barrel blanks of pre-hardened steel are drilled, rifled THEN contoured. IF the contouring were to open up the bore at the muzzle end, then button rifling (others believe cut rifling is the culprit) would be a complete and utter waste of time and money.

As you correctly stated in your follow up post: "Generally considered an accuracy killer to have the bore looser at the muzzle than the breech". However, what you don't state is that an even bigger "accuracy killer" is pushing a bullet the wrong way down the barrel.

So I'm making high end button rifled match barrels and I won't know if I can sell my product until I do all the work and air gauge it? If this were a real issue how would I stay in business?

Barrels do NOT "open up" when contoured. The machining stresses do not mystically effect the steel when we re-contour a barrel but not the manufacturer. Fluted barrels do NOT impart more stresses and ruin the accuracy. And cryo-stress relieving barrels has never been proven to do a thing (the reason there are so few companies left doing this). It's snake oil!

The best way to determine the direction of the bore is to look inside with a bore scope. Cut rifling is obvious. When viewed from the breach it will look smoother. When viewed from the muzzle you can see the edges (like a saw blade in miniature). Button rifled barrels are GENERALLY more smooth but look like ripples in the sand at a beach. The bullet should travel across the more gently sloping backs of the ripples not into the faces of them. If you don't have a bore scope find someone who does and ask them nicely if you can look down the bore of your barrel from both directions with it. I don't know anyone with a bore scope who would turn down anyone who asked nicely.

Running a patch down the barrel will usually offer LESS resistance in the SECOND direction than the first because the patch(es) become compressed on the first pass and offer less resistance on the second. Re-wraping the patch(es) or replacing them for the second pass will tell you nothing of value either since it is impossible to wrap them exactly the same each time. GENERALLY, IF there is a measurable difference in the bore from end to end you are only talking about a couple ten-thousandths (0.0001"). IF you really need to know which end is tighter the ONLY reliable way to know is to gauge it with a plug gauge. AND GENERALLY the tight end IS the muzzle... Not always, only MOST of the time.

You real need to know which direction the tooling marks run. Don't worry about which tighter. And when you re-contour the barrel, reference the bore NOT the OD. Worry about leaving enough meat on the muzzle to prevent failure, NOT opening up the bore on the muzzle end. It will NOT be an issue!