Here's what I've been doing to CZ452's with good results and it will work on your rifle:

First, do as others above have suggested and bed the barrel channel. Full bed is no problem but if not , atleast bed till 2" past the barrel pillar.

(Remember to fill the protruding areas of the pillar dovetail with plastercine so it doesn't hang up on the epoxy.) I also bed the tiny area under the tang - nothing fancy required, just enough to estabilish a level.

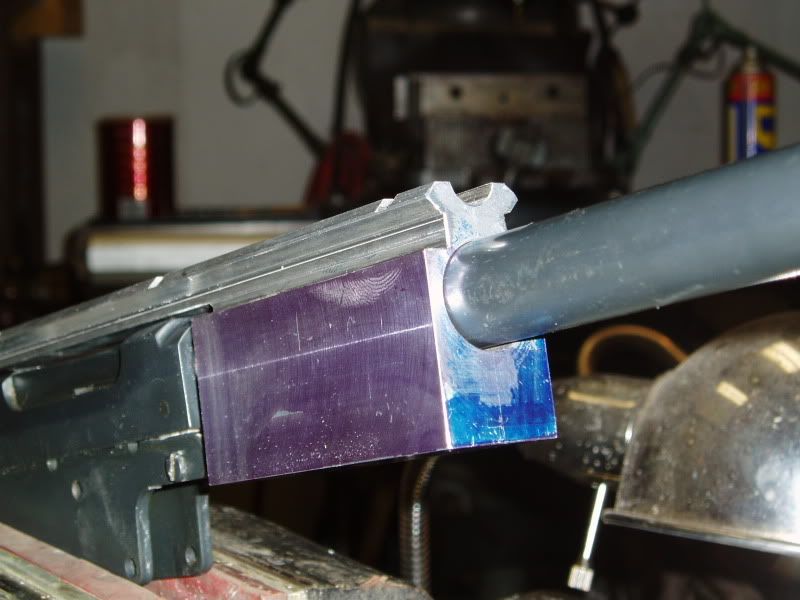

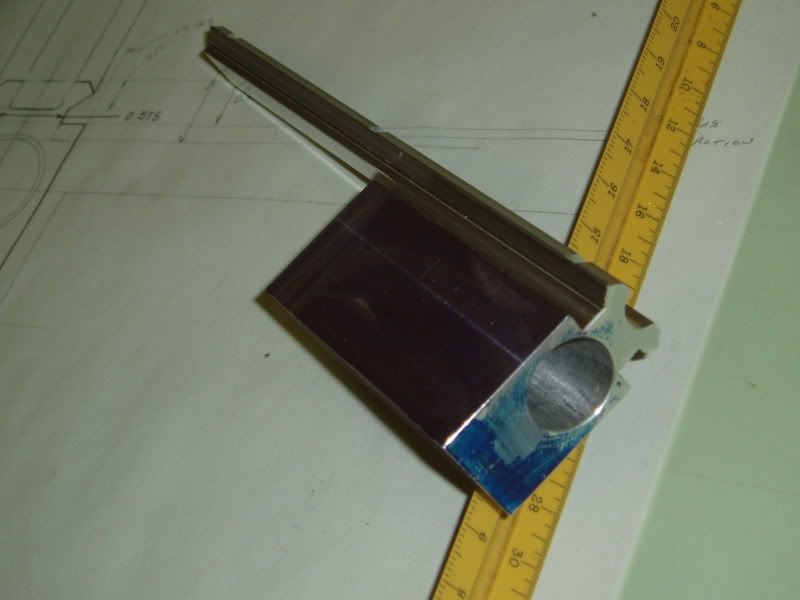

Then - assuming you are a machinist - make up an aluminium pillar for the action screw in the miidle of the receiver. The pillar will need to be a funny shape at the top to fit between the magazine and the trigger group but a little imagination will sort out the design. On CZ's I mill a small flat in this area to provide a mating surface for the pillar. The length of this pillar is critical, either too long or too short and your bedding job becomes redundant.

I start off by sitting the barrelled action in it's new bedding job with barrel screw nipped up and poking the end of my verniers down the action screw hole (with bottom metal fitted) to the receiver to establish nominal length. Add 0.020" so you have something to machine off. Remove action and Drill your stock for your new pillar.

Reassemble and take a reference masurement that will allow you to gauge how high the action is sitting on the pillar. This measurement can be a point to point measurement from the top of the receiver to a corresponding point on the bottom metal or if the stock allows, measuring shims under the tang or even smearing a little bearing blue or stockmakers black on the receiver tang may be useful to see when contact has been made.

Pull the barrelled action out of the stock and re-fit as many times as neccessary , each time removing a few thou' from the length of the pillar and measuring against your initial demension till the receiver sits neatly down on the pillar and against the tang without flexing.

Remember, the height you are aiming for is set by the barrel bedding.

It sounds like a bit of work but isn't really and negates the need to make any permanent mods to the metalwork.

) individual! .....keep us posted on how the gun shoots.

) individual! .....keep us posted on how the gun shoots.