magno_grail

Hot Rolled

- Joined

- May 29, 2014

- Location

- ca, US

Hi All, I recently borrowed a friend's rotary. His is a 17 pin and my machine is 14 pin. I worked out the connections but shortly afterward the rotary began faulting. After taking it apart I found the encoder wheel had been rubbing on the window and wore away the mask. Scratch one encoder. I found a new replacement but 1800 line rather than 2000 line (and 6mm shaft rather than 1/2"). He had a spare motor with a 1/4" shaft so I machined that one down and replaced motor and encoder.

So now the problem is A axis Z channel missing or Z fault. The strange part is it will work to a point and then fault. The Z channel is a once around marker so if it is not working it would fault immediately, not after 10° or 140°. It faults almost immediately if I manually step it at full speed (0.1) but usually not at 0.01.

I was able to go 360° on a test cut with rapids set at 25% but then it started faulting after several steps (58 divisions or just over 6° per step). At 100% rapid it will fault on the first step or when doing Zero Return.

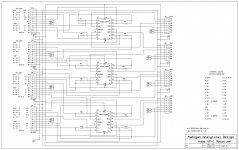

The A axis encoder connection to the MOTIF board is different than the X, Y and Z in that those all go through a receiver board with AM26LS32PC quad RS422 line drivers before connecting to the MOTIF board. The A axis goes directly to the MOTIF board even though there is provision on the receiver board to take the A axis (but no headers and three resistors not mounted). The X, Y and Z encoder cables inside the machine are 11 pin, the A axis is 7 pin. I will not find where the other wires for the A axis should come from until I get full access to the back of the machine.

It appears there must be noise or low signal strength causing the fault. I do not know why they bypassed the receiver board with the A axis. Does anyone have the A axis wired through the receiver board (daughter board mounted on the MOTIF board)? Mine is an early machine (1024).

By the way, you cannot just pin for pin connect a 17 pin rotary to a 14 pin machine as wires were re-purposed.

So now the problem is A axis Z channel missing or Z fault. The strange part is it will work to a point and then fault. The Z channel is a once around marker so if it is not working it would fault immediately, not after 10° or 140°. It faults almost immediately if I manually step it at full speed (0.1) but usually not at 0.01.

I was able to go 360° on a test cut with rapids set at 25% but then it started faulting after several steps (58 divisions or just over 6° per step). At 100% rapid it will fault on the first step or when doing Zero Return.

The A axis encoder connection to the MOTIF board is different than the X, Y and Z in that those all go through a receiver board with AM26LS32PC quad RS422 line drivers before connecting to the MOTIF board. The A axis goes directly to the MOTIF board even though there is provision on the receiver board to take the A axis (but no headers and three resistors not mounted). The X, Y and Z encoder cables inside the machine are 11 pin, the A axis is 7 pin. I will not find where the other wires for the A axis should come from until I get full access to the back of the machine.

It appears there must be noise or low signal strength causing the fault. I do not know why they bypassed the receiver board with the A axis. Does anyone have the A axis wired through the receiver board (daughter board mounted on the MOTIF board)? Mine is an early machine (1024).

By the way, you cannot just pin for pin connect a 17 pin rotary to a 14 pin machine as wires were re-purposed.