I've recently acquired a Bridgeport 2J made in 1976. It's up and running now, through the generous aid of those on this site. The machine is in good used condition. There's wear, but it doesn't appear extreme, as far as I can tell. The machine is likely full of chips and grime.

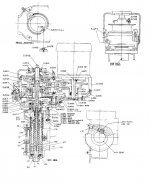

The oiling system is gummed up, so I'll clean the reservoir and try to force a solvent through the system in an attempt to clean it out. My first inclination is to disassemble the machine completely, removing the head, ram, and turret and lifting off the knee, after removing the table. I'd like to inspect and clean the entire machine.

Does this seem advisable? Would you also open the head to clean up any old grime inside? I would appreciate any advice on readying an older Bridgeport Mill for service and/or recommendations regarding related reference material. Thanks for the help!

The oiling system is gummed up, so I'll clean the reservoir and try to force a solvent through the system in an attempt to clean it out. My first inclination is to disassemble the machine completely, removing the head, ram, and turret and lifting off the knee, after removing the table. I'd like to inspect and clean the entire machine.

Does this seem advisable? Would you also open the head to clean up any old grime inside? I would appreciate any advice on readying an older Bridgeport Mill for service and/or recommendations regarding related reference material. Thanks for the help!