Sn 31385

Just returned. Trip didnt go as id hoped. Start with the top.

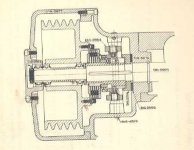

All gears appeared nice however oil level sight glass was broken so its low on oil.

Ways are so-so for damage and scratching. Non hardened. I was unable to detect twist and i forgot my feeler guages so the wear was not measured.

3/5ths of the motor belts were intact (barely) and i hope it was slippage and not the motor worn out causing it to slowly gain speed as well as losing rpm when taking medium depth cuts. I should have investigated further but it all happens so fast. If worst case comes up, can the motor egress the machine through front or back? Looks darn near impossible.

640 rpm top speed with oil splashing through the sight gauge. Only carbide tooling available. It left a miserable finish, i didnt bother to measure taper as i had a host of other problems going on. Crossfeed and compound did not seem rigid. Backlash on the cf was greater than 80, compound about the same. I tightened the gibs but the whole assembly felt wonky.

Does anybody know if the machine can reverse spindle direction. I thought the control lever was supposed to but it does not.

Spindle Gears do not completely mesh when in detent positions, one of the detents is impossible to use. Im guessing handles could be adjusted.

Qc gearbox makes rattly noise in forward and reverse. Quiet in neutral. All gears work. Longfeed dial pulses back and forth sometimes completely turning when power feeding.

Tail stock would not eject the installed chuck. Is it supposed to be wedged out?

There are three weird springs going around the control rod. Any guesses what they could be for.

Control levers do not stay in position. This is annoying.

The longfeed is very tight (taper attachment was loose,) and about every 2 or 3 rotations skips a gear on cue. Likely broken tooth and out of adjustment gibs.

Tooling is incomplete. No chuck spanner, no 11.5 tpi gear. No centers, driveplate or dogs. No hss cutters. A couple holders but very little in the way of cutters. No wrenches. Aloris is chinese i think. No tag or drivescrew holes.

A couple broken handles. Placards and paint are in poor shape. No corrosion though.

No history, no documentation,

Otherwise complete and intact.

Would anybody make an offer? I think i have the ability and time to restore it but is it worth it?

Just returned. Trip didnt go as id hoped. Start with the top.

All gears appeared nice however oil level sight glass was broken so its low on oil.

Ways are so-so for damage and scratching. Non hardened. I was unable to detect twist and i forgot my feeler guages so the wear was not measured.

3/5ths of the motor belts were intact (barely) and i hope it was slippage and not the motor worn out causing it to slowly gain speed as well as losing rpm when taking medium depth cuts. I should have investigated further but it all happens so fast. If worst case comes up, can the motor egress the machine through front or back? Looks darn near impossible.

640 rpm top speed with oil splashing through the sight gauge. Only carbide tooling available. It left a miserable finish, i didnt bother to measure taper as i had a host of other problems going on. Crossfeed and compound did not seem rigid. Backlash on the cf was greater than 80, compound about the same. I tightened the gibs but the whole assembly felt wonky.

Does anybody know if the machine can reverse spindle direction. I thought the control lever was supposed to but it does not.

Spindle Gears do not completely mesh when in detent positions, one of the detents is impossible to use. Im guessing handles could be adjusted.

Qc gearbox makes rattly noise in forward and reverse. Quiet in neutral. All gears work. Longfeed dial pulses back and forth sometimes completely turning when power feeding.

Tail stock would not eject the installed chuck. Is it supposed to be wedged out?

There are three weird springs going around the control rod. Any guesses what they could be for.

Control levers do not stay in position. This is annoying.

The longfeed is very tight (taper attachment was loose,) and about every 2 or 3 rotations skips a gear on cue. Likely broken tooth and out of adjustment gibs.

Tooling is incomplete. No chuck spanner, no 11.5 tpi gear. No centers, driveplate or dogs. No hss cutters. A couple holders but very little in the way of cutters. No wrenches. Aloris is chinese i think. No tag or drivescrew holes.

A couple broken handles. Placards and paint are in poor shape. No corrosion though.

No history, no documentation,

Otherwise complete and intact.

Would anybody make an offer? I think i have the ability and time to restore it but is it worth it?