Yes thats an Agathon like pullscraper from Urben+Kyburz.

One I bought directly from Urben+Kyburz and one I found on a picture of an advertised lathe on the online marketplace "ricardo" here in Switzerland.

I know they are not easy to find.

In the early days Agathon was a machine manufacture company in the city of Solothurn here in Switzerland.

They still exists. Later Urben+Kyburz was founded also in Solothurn. They started to manufacture the inserts for the agathon pull scraper.

Agathon later decided to stop producing such scraper and Urben+Kyburz started to manufacture them.

Unfortunately they stopped as well.

They still have some of the small ones in stock.

Here is a picture with prices (without 8% VAT) from Urben+Kyburz AG.

The short version and the HSS inserts are still available. Also the angled carbide blade

Mine is also a short version. I drilled a hole in the wooden handle and put a stainless steel rod in it.

It works great and when I need the short version again I can pull out the rod and change the angle of the head.

Be aware that you cannot take big amount of material with such a pull scraper.

It is very useful for fine work such as the gauge scraping from Wyler.

For the angle IMHO it should be around 80 degree.

I found some info about the angle in an old German mechanic book from 1954.

It only says the angle 'beta' (ß) should be less than 90 degree for pullscraping

More important is to get a really good edge.

Sharpening the blade by hand on a diamond grinding wheel is very hard.

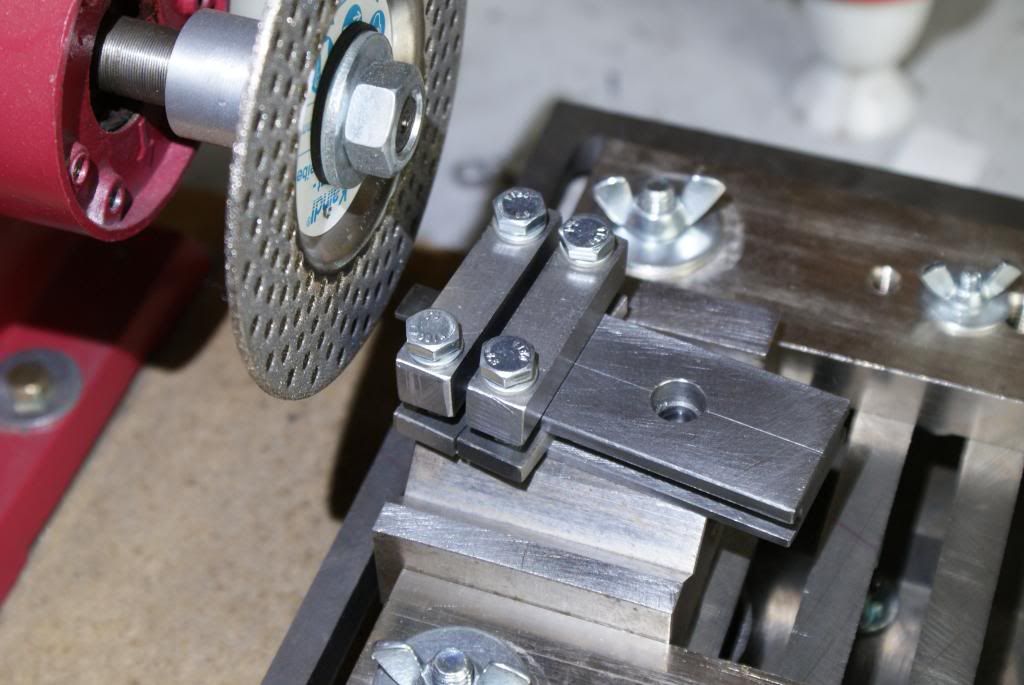

I use my small universal grinding machine for sharpening the blade

At the moment I only use pull scraping to scrape patterns and to get into the corners of the dovetail.

For the rest I still use push scraping.

Best regards

Juergen