comment: every time i take out these instruments, something unexpected happens.

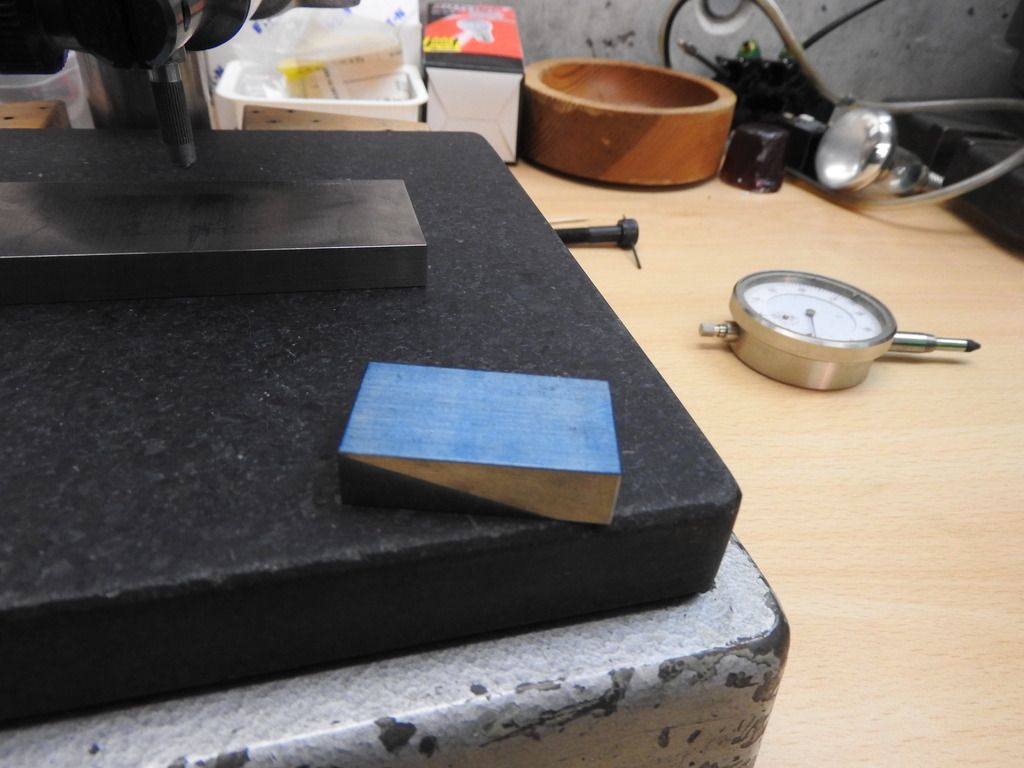

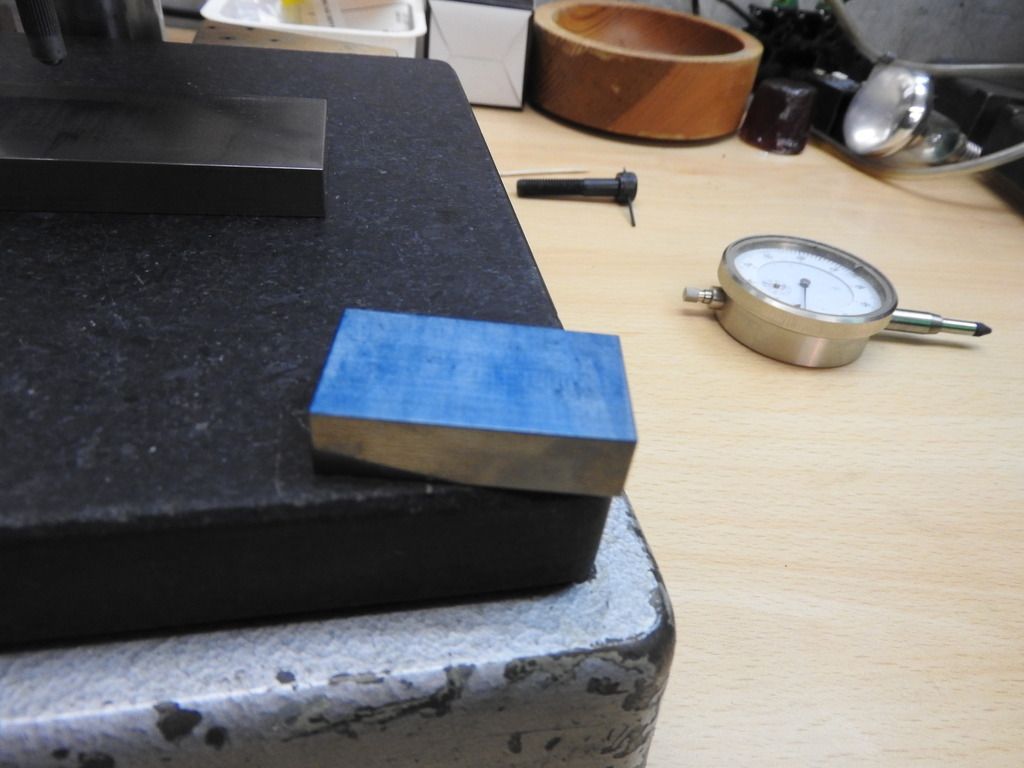

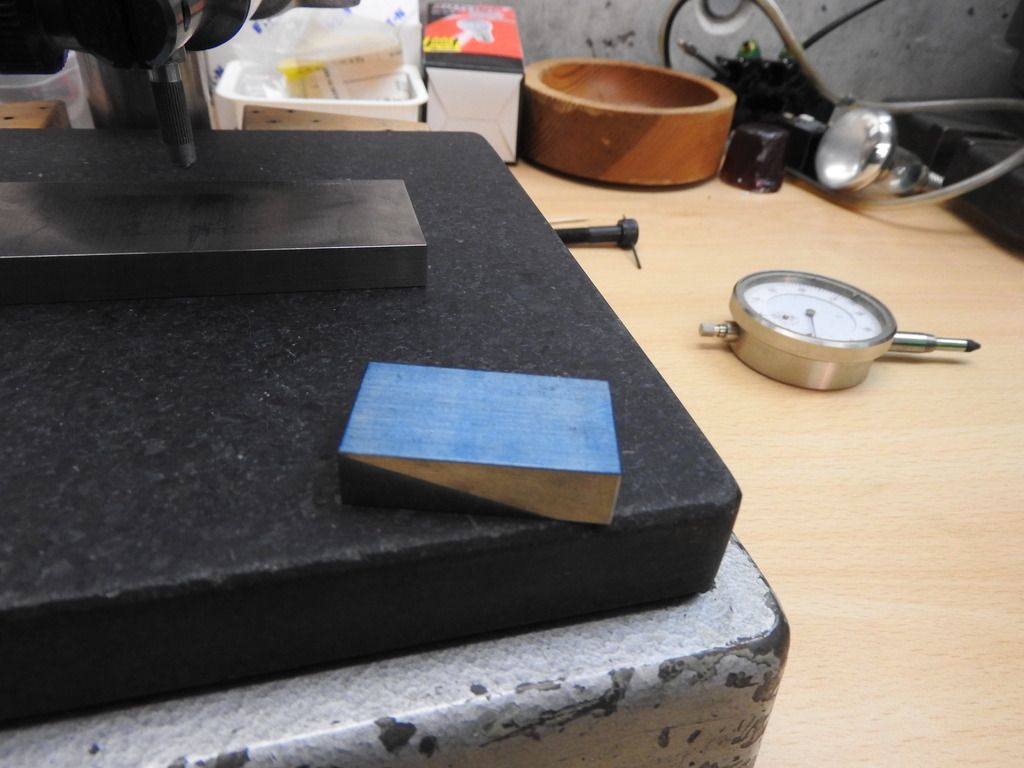

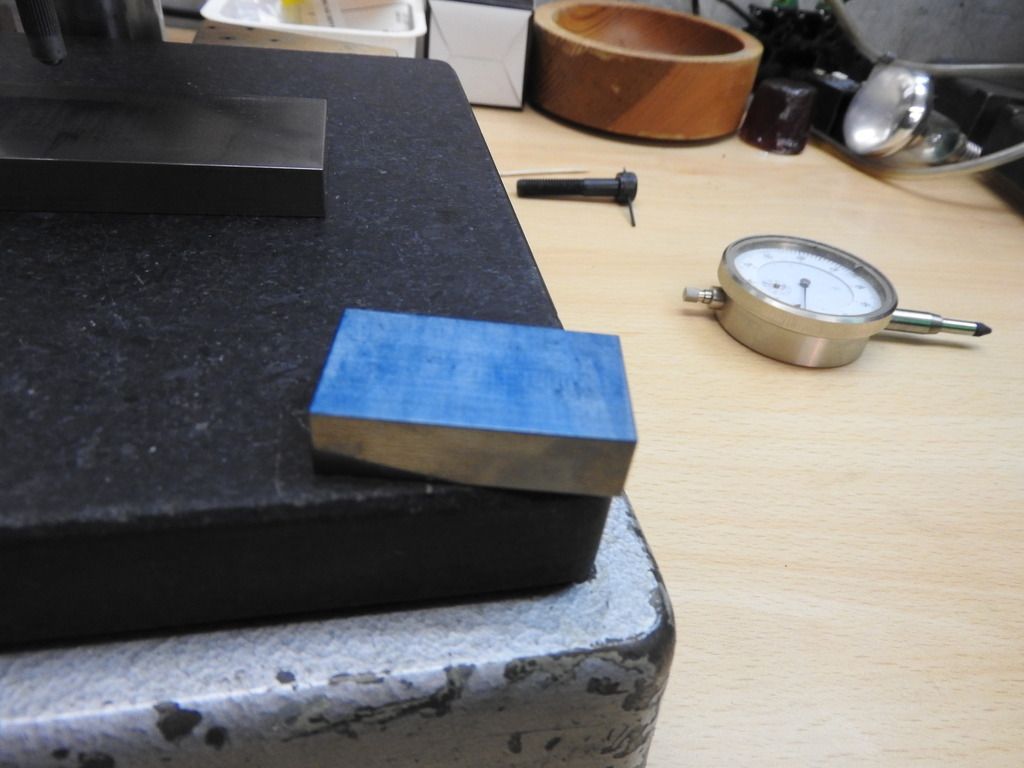

i cleaned the two jorgensen gage blocks with alcohol and wrung them together. i got - 2.75 mu.

i then put a haze of blue on the small block: -1.6 mu.

some more blue (obviously the block doesnt blue up well) yielded +1.3 mu. a lot (too much) blue resulted in +6.0 mu, but afted wringing i got -4.0. afted whiping it of, the instrument surprisingly settled to -2.75 again. so my conclusion is that the thickness of blue is 2-2.5 mu.

every time i waited for about 5 min, before taking the measument. i saw shrinking of around 0.2 mu. in the morning i found -3.4 mu on the scale.

btw, after cleaning with alcohol it showed -4.1 mu (starting from -3.4). a very light coating with charcoal lighter yielded -4.1 and a thicker coat -4.8 mu. whet wetted completely i got -5.1 mu.

would anybody care to repeat my experiment to confirm the results?

i cleaned the two jorgensen gage blocks with alcohol and wrung them together. i got - 2.75 mu.

i then put a haze of blue on the small block: -1.6 mu.

some more blue (obviously the block doesnt blue up well) yielded +1.3 mu. a lot (too much) blue resulted in +6.0 mu, but afted wringing i got -4.0. afted whiping it of, the instrument surprisingly settled to -2.75 again. so my conclusion is that the thickness of blue is 2-2.5 mu.

every time i waited for about 5 min, before taking the measument. i saw shrinking of around 0.2 mu. in the morning i found -3.4 mu on the scale.

btw, after cleaning with alcohol it showed -4.1 mu (starting from -3.4). a very light coating with charcoal lighter yielded -4.1 and a thicker coat -4.8 mu. whet wetted completely i got -5.1 mu.

would anybody care to repeat my experiment to confirm the results?

....one should not over think this....I have been doing that on many things, but you want at least 3 tenths of depth, and to get only the highs hit you need blue that is thinner than 3 tenths. The highs will sink into the film any way, and the real highs will push the blue out all the way and make direct contact with the plate. I also find that blue that is too thin will give you false readings, just as much as blue that is too thick. At the last class Paulo and i were at times looking for that "encouragement" so we slapped on a bit more blue here and there. The thickness of the blue you want will depend on where you want to be, if you are trying to get an even 10 PPI coverage on an SE or a surface plate, you may need more blue, if you want to go from 20 PPI to 40 you may need a very thin layer of blue. Listen to Richard, the guy who knows, he is telling you to read the spots, the gradation of blue, and adjust the blue as you need it, put away the 1 micron gage, you cannot put an even coat of 2 micron thick anyway. If your spots are too faint and not even, put on more blue, if you get blue in the valleys wipe some off, or maybe you are not scraping deep enough. If your part is not hinging right you have more to worry about then the thickness of the blue. The beauty of this stuff is that you do not need laser interferometry and ultra-precise temperature controlled environments to achieve 0.00005 straightness over 12". Remeber not to park on the grass, and the other for rules Richard made us repeat randomly.

....one should not over think this....I have been doing that on many things, but you want at least 3 tenths of depth, and to get only the highs hit you need blue that is thinner than 3 tenths. The highs will sink into the film any way, and the real highs will push the blue out all the way and make direct contact with the plate. I also find that blue that is too thin will give you false readings, just as much as blue that is too thick. At the last class Paulo and i were at times looking for that "encouragement" so we slapped on a bit more blue here and there. The thickness of the blue you want will depend on where you want to be, if you are trying to get an even 10 PPI coverage on an SE or a surface plate, you may need more blue, if you want to go from 20 PPI to 40 you may need a very thin layer of blue. Listen to Richard, the guy who knows, he is telling you to read the spots, the gradation of blue, and adjust the blue as you need it, put away the 1 micron gage, you cannot put an even coat of 2 micron thick anyway. If your spots are too faint and not even, put on more blue, if you get blue in the valleys wipe some off, or maybe you are not scraping deep enough. If your part is not hinging right you have more to worry about then the thickness of the blue. The beauty of this stuff is that you do not need laser interferometry and ultra-precise temperature controlled environments to achieve 0.00005 straightness over 12". Remeber not to park on the grass, and the other for rules Richard made us repeat randomly.