Richard King

Diamond

- Joined

- Jul 12, 2005

- Location

- Cottage Grove, MN 55016

During my last Class Tim one of the students showed this old dog a new trick. The tapered slip stones I give out during the class get contaminated with bluing, high lighter and grit. I have cleaned them in the past by squirting them with brake cleaner, rubbed 2 of them together with go-go, laid them on emery paper on a flat surface like an old surface plate, put diamond lapping compound on a lapping plate and rubbed the stone to it, used tooth paste and brush under hot water tap, etc.

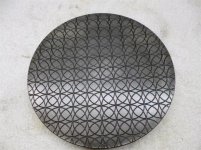

Others have told me they use a Harbor Freight diamond lap. Tim showed us something the Old timers at Ingersoll used when he worked there. Rub the stone on a Wet sheet of cardboard with mineral spirits and we used Windex. Hell if it didn't clean the stone in a 1/2 dozen swipes. Was crazy how will it worked.

Others have told me they use a Harbor Freight diamond lap. Tim showed us something the Old timers at Ingersoll used when he worked there. Rub the stone on a Wet sheet of cardboard with mineral spirits and we used Windex. Hell if it didn't clean the stone in a 1/2 dozen swipes. Was crazy how will it worked.