Glenn Brooks

Aluminum

- Joined

- Nov 16, 2014

- Location

- Woodinville, Wa

Anyone recommend current vendors for hand held scrapers and replacement blades?

Thanks

Glenn B.

Thanks

Glenn B.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

For fucks sake, your from Switzerland. Have you not heard of Biax, Electro mechanical scrappers.Are there non-handheld scrapers?

For fucks sake, your from Switzerland. Have you not heard of Biax, Electro mechanical scrappers.

Better than the Germans though!

For fucks sake, your from Switzerland. Have you not heard of Biax, Electro mechanical scrappers.

Ihre Aufgaben:

Ausmessen von komplexen Teilen

Schaben von Grossteilen mit genauen Führungsauflagen

Schaben von Passflächen bei Abstimmarbeiten

Kontrolle von Hilfsmitteln für die Montage

Rund- und Flachschleifen von Kleinteilen, Einzelteilen und Kleinserien

Unterstützung der Fabrikation Drehen/Fräsen, Montage und Qualitätssicherung

<Snip>

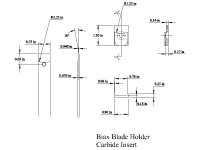

PS For the scraping class I built three very simple scrapers that consist in a piece of bar stock with a piece of 1/4-20 brazed at one end (to screw on one of those 4" rubber disks that you generally chuck onto an hand-held drill as backing for a sanding disk) and milled a recess on the other. I made a rudimentary clamp mocking the one you find on Sandwik scrapers. Unfortunately, I never took any picture of them and they're at Tuckahoe, right now. If you're interested, I can post a few pictures earlier next year.

GF is looking for a scaper hand at Liechti Engineering in Langnau im Emmental.

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.