JB Bergman

Hot Rolled

- Joined

- Nov 8, 2006

- Location

- Slayden, Mississippi

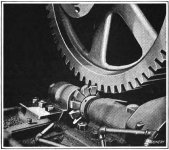

Here is you opportunity to get that gear cutting machine you have always wanted, just in time for Christmas too!

This was great uncle Mikes, I got it and the Pratt vertical shaper from him.

The machine is a Newark, can cut a 36 inch gear with a 6 inch face. I think it is a copy of the B&S machines of the same vintage. It works and works well for what it does. It HAS the usually missing outboard support for big gears. Also included are the arbors for the gear blanks, arbors for the cutters a large group of indexing change gears and speed change gears.

The best part is the 450 plus involute gear cutters that have been properly stored through the years. The largest are 3 or 4 pitch down to 48 pitch. Keep the cutters you need and sell the rest! I need the space and don't have the time. I can give the new owner a couple good ideas for customers, not lots of easy money, just over looked repair work.

2200.00 for it all. Come and get it.

JB Bergman

This was great uncle Mikes, I got it and the Pratt vertical shaper from him.

The machine is a Newark, can cut a 36 inch gear with a 6 inch face. I think it is a copy of the B&S machines of the same vintage. It works and works well for what it does. It HAS the usually missing outboard support for big gears. Also included are the arbors for the gear blanks, arbors for the cutters a large group of indexing change gears and speed change gears.

The best part is the 450 plus involute gear cutters that have been properly stored through the years. The largest are 3 or 4 pitch down to 48 pitch. Keep the cutters you need and sell the rest! I need the space and don't have the time. I can give the new owner a couple good ideas for customers, not lots of easy money, just over looked repair work.

2200.00 for it all. Come and get it.

JB Bergman