We have a couple of 2.5-ton-rated pallet jacks in the shop, one from HF and another with narrow forks by a good American maker, name escapes me now. A few of our machine tools that need moving occasionally weigh close to 6000 lbs, so I realize I shouldn't use the 5k lb. jacks to move them, but sometimes we must. I've moved up to about 5800 lbs with one and noticed it was very hard to pump up, and the load couldn't be lowered gently, it came down with a bang. But months later the pallet jack is doing fine, nothing broke and we continue to use it. Any general guidance on overloading pallet jacks? Anyone know a source for ones of higher capacity than 2.5 T.?

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Must overload my 2.5 ton pallet jack, what will happen?

- Thread starter Cannonmn

- Start date

- Replies 12

- Views 6,882

Peter from Holland

Diamond

- Joined

- Jan 15, 2005

- Location

- The Netherlands

You recognize a good pallet jack by the ability to lower it gently even on full capacity

All the chaep ones lower with a bang

The ones I have all have a bypass so at a certain weight you can keep pumping but the load does not rise anymore

What you can do then is put under a second palletjack and help him lift Keep the load low

Peter

All the chaep ones lower with a bang

The ones I have all have a bypass so at a certain weight you can keep pumping but the load does not rise anymore

What you can do then is put under a second palletjack and help him lift Keep the load low

Peter

G

guest

Guest

Toe jack and skates. Rent'em if you don't want to buy'em.

Save your pallet jacks for moving pallets...

.02, ymmv.

Save your pallet jacks for moving pallets...

.02, ymmv.

Scottl

Diamond

- Joined

- Nov 3, 2013

- Location

- Eastern Massachusetts, USA

This sounds like risky business. If you look at a diagram of how a hydraulic jack works what you have is a reservoir, pump, and lift cylinder. There is a check valve (steel ball in contoured seat) that prevent fluid from going back into the reservoir when you relax the pump handle. There is a valve that bypasses that fluid route so you can deliberately lower it back down.

When a jack fails several things can happen. Fluid may bypass the seals, the release valve may not close, or the check valve can "blow", which means the seat has eroded under pressure. On dismantled jacks I've looked at when the check valve fails there is usually a dark streak where the seat was eroded by a high velocity stream of fluid. Usually the seat is an integral part of the steel component that it's in and must be re-cut and lapped in. That "bang" is a sign that the pressure bypassed one of the above and the only thing limiting how fast the load comes down is the size of the leak. If I "jerked" the release valve wide open on a floor jack I could drop the vehicle down hard enough to make it bounce on the tires. The same thing can happen if enough of the valve tip gets broken off. In some case there is a relief valve that will open during an overload. It will reseat but it will open again on the next overload. Many lower-priced jacks do not have that feature. I'm not sure I would even trust a cheapo at its full rated load.

Don't do it! You are way beyond safety margins.

When a jack fails several things can happen. Fluid may bypass the seals, the release valve may not close, or the check valve can "blow", which means the seat has eroded under pressure. On dismantled jacks I've looked at when the check valve fails there is usually a dark streak where the seat was eroded by a high velocity stream of fluid. Usually the seat is an integral part of the steel component that it's in and must be re-cut and lapped in. That "bang" is a sign that the pressure bypassed one of the above and the only thing limiting how fast the load comes down is the size of the leak. If I "jerked" the release valve wide open on a floor jack I could drop the vehicle down hard enough to make it bounce on the tires. The same thing can happen if enough of the valve tip gets broken off. In some case there is a relief valve that will open during an overload. It will reseat but it will open again on the next overload. Many lower-priced jacks do not have that feature. I'm not sure I would even trust a cheapo at its full rated load.

Don't do it! You are way beyond safety margins.

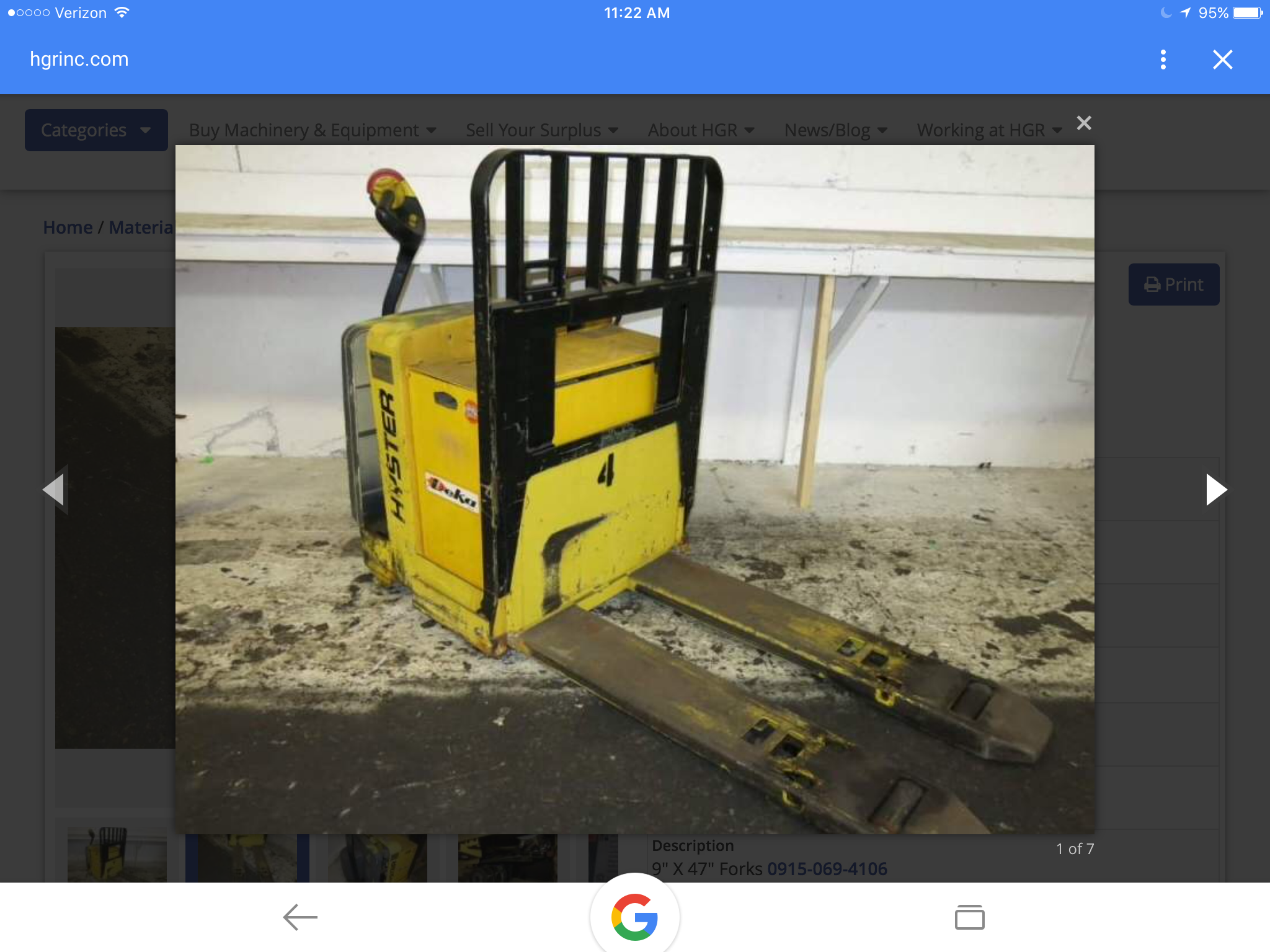

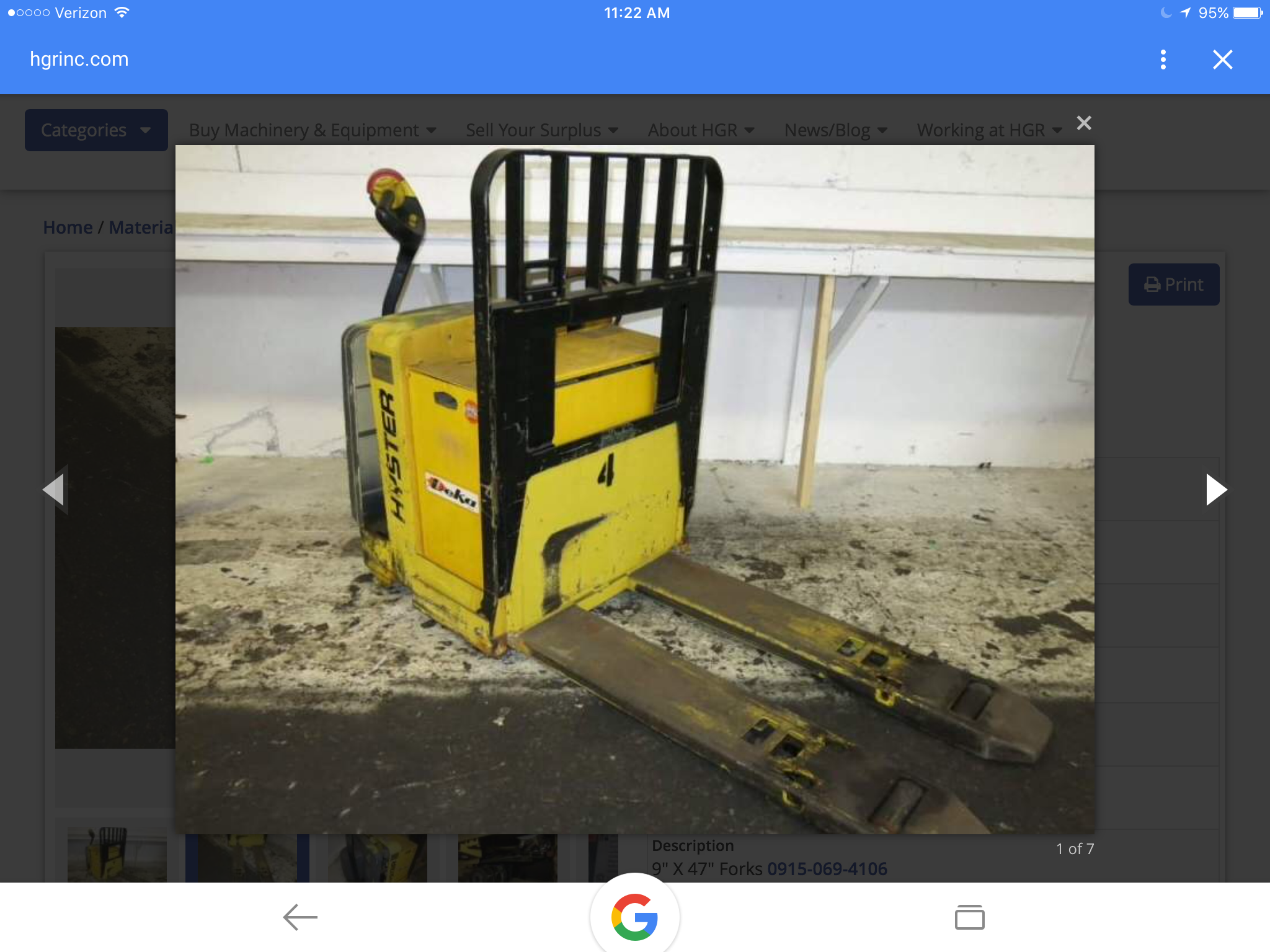

Thanks, good ideas. We keep many of our machines on heavy or reinforced pallets to ease movement when doing so doesn't impact accuracy or safety. So a few min. ago I bought the 4-ton cap. Lift pictured, on discount today, knowing it might need a new battery. I do have a "rol-lift" that would work for toe jacks, but only one half of the normal pair, so will start looking for those skates you mention, had not heard the term before in my limited mat'l. handling experience. A friend had a machinery-sales shop where I spent a fair amount of time and he used his electric pallet jack every day in preference to his forklift or other devices, and I saw how useful these beasts can be.

Mud

Diamond

- Joined

- May 20, 2002

- Location

- South Central PA

Here's the first 2 that came up from googling heavy duty pallet jack -

Heavy Duty Pallet Jack | Lift-Rite Titan Heavy Duty Pallet Jacks

Heavy Duty Pallet Truck, 11,���lb Capacity Pallet Jack At Globalindustrial.Com

I had somewhat over 5K on a 5500 lb Lift-rite one time, it felt shaky enough that I'm not going to do it again. I don't see a lot of safety margin on pallet jacks.

Heavy Duty Pallet Jack | Lift-Rite Titan Heavy Duty Pallet Jacks

Heavy Duty Pallet Truck, 11,���lb Capacity Pallet Jack At Globalindustrial.Com

I had somewhat over 5K on a 5500 lb Lift-rite one time, it felt shaky enough that I'm not going to do it again. I don't see a lot of safety margin on pallet jacks.

Illinoyance

Stainless

- Joined

- Aug 24, 2015

Overloading a pallet jack will definitely shorten its life. I wouldn't be overly concerned about structural failure because the load can't fall far. I have seen a number of pallet jacks with cracked welds. I suspect more from fatigue than overstress.

Scottl

Diamond

- Joined

- Nov 3, 2013

- Location

- Eastern Massachusetts, USA

Cannonmn,

WONDERFUL!

That Hyster will give you many years of service. Aside from battery and occasional (but not that common) hydraulic issues one of the main wear issues is the front rollers and bushings. Some places neglect keeping them lubed. They are not difficult or expensive to replace when needed.

WONDERFUL!

That Hyster will give you many years of service. Aside from battery and occasional (but not that common) hydraulic issues one of the main wear issues is the front rollers and bushings. Some places neglect keeping them lubed. They are not difficult or expensive to replace when needed.

I've never cracked a weld on one. What usually happens when manual pallet jack is overloaded is the forks get bent outward....still works but forks are forever not parallel to each other anymore.Overloading a pallet jack will definitely shorten its life. I wouldn't be overly concerned about structural failure because the load can't fall far. I have seen a number of pallet jacks with cracked welds. I suspect more from fatigue than overstress.

I've overloaded many electric pallet jacks, with no harm to the jack but they are typically built way heavier duty than manual jacks. Many times have used electric pallet jacks as motorized mules to move long heavy machines that are on skates at the other end. Sometimes had to lower the pallet jack end on the jack forks with a toe jack as the weight was beyond the capacity of the jack to raise the load, so the jack was for motion purposes only.

Overloading a manual pallet jack seems silly due to muscle power needed to move it around. I always preach the charms of electric pallet jacks but few seem to listen. Manuals do have the advantage for certain machines however...like where the battery of an electric would get in the way so you can't get under the machine as far as you'd like. There is a solution for that as well however...use short height deep cycle golf cart batteries instead of the tall typical pallet jack battery.

I have a 10,000 lb manual pallet jack by Lift Rite but I ever use it anymore...should sell it... try moving 10,000 lbs around by hand....can be done on a perfect floor, but you end up doing more pry bar moving the jack than normal pulling.

That's another aspect of a proper electric pallet jack that is way better....they have an extra set of heavy duty casters under the steer end of the jack forks that ride just above the floor surface. So if the load tips a hair, those casters keep it from tipping any more.I had somewhat over 5K on a 5500 lb Lift-rite one time, it felt shaky enough that I'm not going to do it again. I don't see a lot of safety margin on pallet jacks.

Plus they have brakes ! The newer AC drive ones with regenerative brakes are the Cat's Meow.....

I've never cracked a weld on one. What usually happens when manual pallet jack is overloaded is the forks get bent outward....still works but forks are forever not parallel to each other anymore.

I've overloaded many electric pallet jacks, with no harm to the jack but they are typically built way heavier duty than manual jacks. Many times have used electric pallet jacks as motorized mules to move long heavy machines that are on skates at the other end. Sometimes had to lower the pallet jack end on the jack forks with a toe jack as the weight was beyond the capacity of the jack to raise the load, so the jack was for motion purposes only.

Overloading a manual pallet jack seems silly due to muscle power needed to move it around. I always preach the charms of electric pallet jacks but few seem to listen. Manuals do have the advantage for certain machines however...like where the battery of an electric would get in the way so you can't get under the machine as far as you'd like. There is a solution for that as well however...use short height deep cycle golf cart batteries instead of the tall typical pallet jack battery.

I have a 10,000 lb manual pallet jack by Lift Rite but I ever use it anymore...should sell it... try moving 10,000 lbs around by hand....can be done on a perfect floor, but you end up doing more pry bar moving the jack than normal pulling.

Electric mule-yes my friend used his that way to drag heavy things out of the very-crowded shop so the forklift could get at them. It is surprising how much weight they can drag across a concrete floor-and I can't recall any skidding, and these electric jacks only weigh 2000-3000 lbs. from the few I've looked at. I don't know how high the one I just bought will go but the one he had seemed like it'd raise about a foot off the ground.

I found out the hard way last week what happens when you overload one fork of a pallet jack. Of course when the whole thing is overloaded, it bypasses the safety relief, but you can tear stuff up if you put way more weight on one fork than the other.

We were lifting a tank in a milk plant that was right at the pallet jack capacity (5,500 lb). The tank shifted and one fork of the pallet jack slipped out. We were aware this might happen so we were close to the ground so the tank slipping didn't hurt the tank. The pallet jack didn't fair so well. With right at 5,500 lb on one fork, it folded the rod that raises the front wheels up like a pretzel.

We were able to take the rod out, straiten it in a press, and complete the job.

We were lifting a tank in a milk plant that was right at the pallet jack capacity (5,500 lb). The tank shifted and one fork of the pallet jack slipped out. We were aware this might happen so we were close to the ground so the tank slipping didn't hurt the tank. The pallet jack didn't fair so well. With right at 5,500 lb on one fork, it folded the rod that raises the front wheels up like a pretzel.

We were able to take the rod out, straiten it in a press, and complete the job.

Chknives

Aluminum

- Joined

- Jan 16, 2015

- Location

- Oregon city, Oregon

From my experience they don't like it. They just drop usually or it's very hard to move them small amounts. They also usually won't lift much over without it getting very hard to lift or not lifting it at all.