Captdave

Titanium

- Joined

- Sep 24, 2006

- Location

- Atlanta, GA

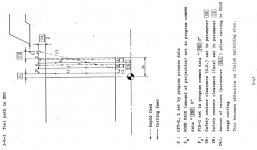

Anyone remember the parameter for adjusting tool over shoot for facing OP on a T+?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

No tit if you hand wheel it.

I thought that Edge process had the 2X overshoot built in as well?

No tit if you hand wheel it.

I thought that Edge process had the 2X overshoot built in as well? Interestingly, if you play with the tool nose radius in the tool data page nothing changes, tit wise anyways.

I hate using the prioritization function! Once you use it, every time after that when you make ANY kind of change to the program, you have to go back and re-prioritize. Very annoying.Interesting. When I forgot to change tool radius with an insert change was the time I had this issue. (I'm on a T2 control)

I have a hypothesis about maybe why (assuming all the tool data is correct)...

Are you doing layout in Program Priority or Roughing Priority?

It would be interesting to know if trying it both ways, one way might remove the tit.

I hate using the prioritization function! Once you use it, every time after that when you make ANY kind of change to the program, you have to go back and re-prioritize. Very annoying.

Our T-2's overshoot center with EDG. I will check our parameters to see if I can find it for you.

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.