OKIEMACHINIST

Aluminum

- Joined

- Jan 24, 2006

- Location

- OKLAHOMA

We've racked our brains for 2 days on this. Mazak wasn't much help, but on our new Integrex i400 with Matrix2 control, we are having problems with a subprogram.

Not sure if is a parameter or program error, but was able to successfully do it on our old Integrex with a Fusion Control.

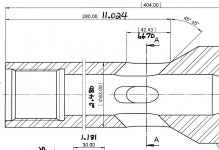

We are trying to machine a deep slot that is on a 45 deg angle.

We have a manual program in the main program that puts the tool in the starting X,Y, Z, &B position.

Then it switches to the sub program that loops and profiles the slot with an incremental step down.

The problem is when we run the main program and it switches to the sub program, the B-axis wants to index from the 45 degree position back to the 90 degrees before it runs the subprogram.

There's nothing in the program that tells the B-axis to move to 90 degrees. It just does it by default, I guess.

Has anyone else had this problem of having the B-axis wanting to go to 90 degrees? If so, any help would be greatly appreciated.

Not sure if is a parameter or program error, but was able to successfully do it on our old Integrex with a Fusion Control.

We are trying to machine a deep slot that is on a 45 deg angle.

We have a manual program in the main program that puts the tool in the starting X,Y, Z, &B position.

Then it switches to the sub program that loops and profiles the slot with an incremental step down.

The problem is when we run the main program and it switches to the sub program, the B-axis wants to index from the 45 degree position back to the 90 degrees before it runs the subprogram.

There's nothing in the program that tells the B-axis to move to 90 degrees. It just does it by default, I guess.

Has anyone else had this problem of having the B-axis wanting to go to 90 degrees? If so, any help would be greatly appreciated.