Well i got it. As i said earlier i've spent a rediculous amount of time with the electrical manual. As it turns out on my machine the bar feeder bit (bit 6) and the m6/m7 bit (bit 1) both need to be set in op1. Also the bar feeder on switch needs to be set. It's crazy in this thing there are other op1 param bits that are taken into account in the chuck open/close logic but it gave a 216 error if any others were set.

Beganboll i did try two m7's and that did not work and looked some at the dual foot switches and that appears to require feedback switches on the chuck open/close which my machine does not have

This is a great relief- Thanks! I have gotten pretty familiar with the ladder diagram and diagnotic mode so that is good.

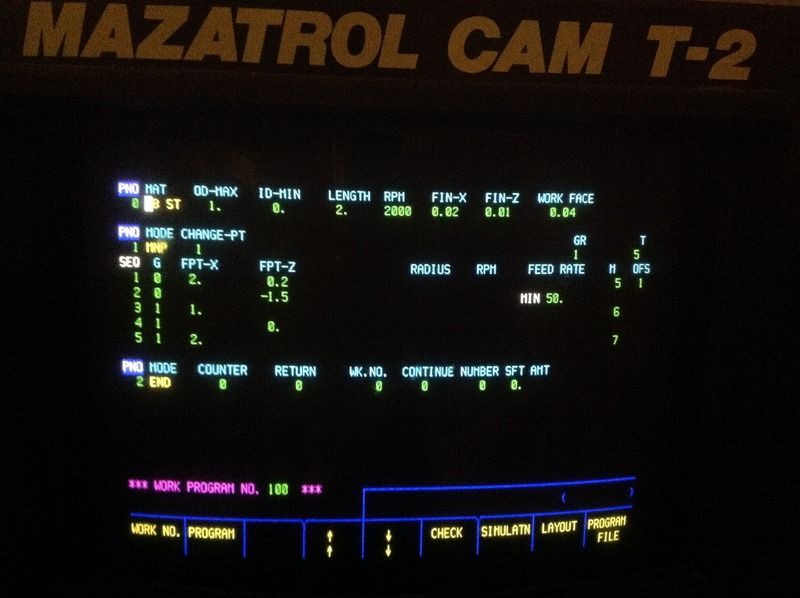

View attachment 186210View attachment 186211