Hi....wondering if someone can help. We have a Mazak, Mazatrol CAM T-3, Slant Turn 30 ATC-MC. There is an intermittent problem with the spindle stopping when it changes gears (maybe 10-12 times a day). If you push the spindle in any direction it will resume operation. This problem can go on for a couple of days and stop for months. An error code "252" shows up but it is unrelated to the spindle. Any thoughts?

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mazak Slant Turn 30 ATC-MC

- Thread starter toolex

- Start date

- Replies 10

- Views 4,217

Philabuster

Diamond

- Joined

- Jul 12, 2006

- Location

- Tempe, AZ

How well does it change gears manually? The gear shift is controlled by a hydraulic cylinder and you can adjust the pressure if it is low. It could also be a faulty limit switch, which tells the machine it shifted into the correct gear.

It would do it sometimes even when I change the gears manually till I push the spindle with my hand to help it along. the pressure has been beyond the green mark for quite some time. So I don't know if raising it up more would do anything. the hydraulic shaft has always been in between the switches when I get an alarm. it has never given me an alarm while the shaft is on a switch

benganboll

Hot Rolled

- Joined

- Feb 23, 2015

- Location

- Sweden Östersund

I have the same machine.

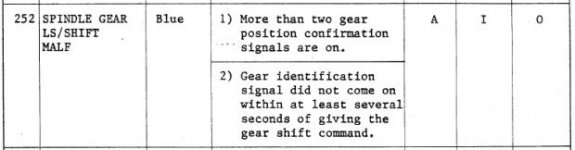

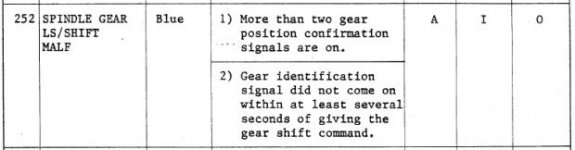

252 is related to spindle gears.

When it happens have a look the these switches before you push the chuck in any direction.

Maybe you need to clean, adjust or lubricate the switches but to me it sounds like the gears are not in position. (it stops between two switches).

EDIT: Did not read through the thread before answering

My machine is spinning the spindle slowly while shifting to prevent this from happening, could it be a timer parameter that is incorrect or its shifting to slow.

I could take a video of the speed of the hydraulic shift cylinder so you can compare if you want.

252 is related to spindle gears.

When it happens have a look the these switches before you push the chuck in any direction.

Maybe you need to clean, adjust or lubricate the switches but to me it sounds like the gears are not in position. (it stops between two switches).

EDIT: Did not read through the thread before answering

My machine is spinning the spindle slowly while shifting to prevent this from happening, could it be a timer parameter that is incorrect or its shifting to slow.

I could take a video of the speed of the hydraulic shift cylinder so you can compare if you want.

benganboll

Hot Rolled

- Joined

- Feb 23, 2015

- Location

- Sweden Östersund

Do you have the spare toolmagazine on the backside of your machine so you can load it with 32,64 or 96 tools?

the problem is a crap shoot on when it will happen, but I believe a video will be able to prove if my cylinder shifts at the proper speed except when it occurs or that it never shifts at the proper speed. So if you could take a video I would appreciate it. thanks in advance

benganboll

Hot Rolled

- Joined

- Feb 23, 2015

- Location

- Sweden Östersund

benganboll

Hot Rolled

- Joined

- Feb 23, 2015

- Location

- Sweden Östersund

You did not answer if you do you have the spare toolmagazine on the backside of your machine so you can load it with 32,64 or 96 tools?

If you do, I want you to see if you have any hidden parameters.

I have the 32 tool magazine but I cant get it to work.

If you do, I want you to see if you have any hidden parameters.

I have the 32 tool magazine but I cant get it to work.

benganboll

Hot Rolled

- Joined

- Feb 23, 2015

- Location

- Sweden Östersund

Here is another trick for troubleshooting:

If you look in the schematics on PC inputs you will find adresses to the gear switches (H3-0, H3-1, H3-2 AND H3-3).

H3 is the adress, and each adress has 8 bits (0-7)

Then you look at the diagnostic page on the machine and place the coursor over the H and press 3 and input.

Now you can see the switches at bit 0-3.

Mine is in gear 1 and bit 1 is active.

If you do a program that uses gear 1 and gear 3 a lot you monitor the bits to see if you have a sticky or non working switch.

If you look in the schematics on PC inputs you will find adresses to the gear switches (H3-0, H3-1, H3-2 AND H3-3).

H3 is the adress, and each adress has 8 bits (0-7)

Then you look at the diagnostic page on the machine and place the coursor over the H and press 3 and input.

Now you can see the switches at bit 0-3.

Mine is in gear 1 and bit 1 is active.

If you do a program that uses gear 1 and gear 3 a lot you monitor the bits to see if you have a sticky or non working switch.

hitandmiss

Titanium

- Joined

- Jul 31, 2010

- Location

- Rochester, NY USA

One other thing to check if the gears don't shift until the spindle is rotated. Go to high gear, then start the spindle at 10 RPM and see if it rotates smoothly with no stopping or jumping. When things like this happen and the spindle does not rotate properly at low RPM the real problem is in the power supply in the FR-SE spindle control. It will be missing at least one output out of the 20 or so that it has. It may work fine then not work, quite hard to troubleshoot.

Bill

Bill

wippin' boy

Diamond

- Joined

- Sep 14, 2005

- Location

- il.

One other thing to check if the gears don't shift until the spindle is rotated. Go to high gear, then start the spindle at 10 RPM and see if it rotates smoothly with no stopping or jumping. When things like this happen and the spindle does not rotate properly at low RPM the real problem is in the power supply in the FR-SE spindle control. It will be missing at least one output out of the 20 or so that it has. It may work fine then not work, quite hard to troubleshoot.

Bill

yeah

I'm on this train with bill

the thing should be rotating itself and is not for some reason

wb

Similar threads

- Replies

- 3

- Views

- 516