will_0000

Aluminum

- Joined

- Dec 16, 2012

- Location

- Great Britain

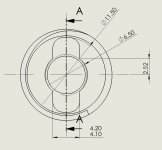

I have been running 2 axis Mazak's for quite some time but have just acquired a SQT10M. It is my first go with driven tooling and I have a shaped profile as shown to put on the front face of the part. I have programmed this with line left using a 3mm endmill. The program runs fine and produces the part correctly. However I am not quite sure how the offsets work with the driven tooling. I am 0.03mm under the 4.10 width but 0.25mm under the 6.5mm and 11.50mm diameters. My understanding is that I need to offset the endmill diameter to bring the size into the 4.10/4.20 tolerance(which diameter do I change?) but what offset should I be adjusting to bring the diameters in (x?).

Thanks

Will

Thanks

Will