I need some help with a Quick Turn 15. I have owned the lathe for several years and it has been very reliable. The control malfunctioned about 4 months ago and was sent out to Mitsubishi for repair. When I installed the control and input the parameters everything worked except a few of the soft keys. Turret unclamp, gear selection, work light, machine lock. I contacted Mits and they sent out a technician. The tech stayed here 2 days and never got the machine up and running. He suggested that I call Mazak. I contacted Mazak and could never get a tech out to look at the machine. I called an independent (who used to work for Mazak and is very competent) to come out and work on the machine. He had no luck either and worked over the phone with the Mits tech to try to resolve the issue. They came to the conclusion that the ram chips must be corrupted. I purchased all new Ram chips from Mazak ($1800.00) and this made no difference. At this point the control and the front panel were sent to Mits who kept them for at least a month. After extensive testing no problems were found and the units were returned. The independent tech came back out and installed the parts again and the same problem persists. He has concluded that it must be a parameter issue. He has sent the parameters to Mits that are loaded in the control to see if they can duplicate the problem on a control at their facility. I don't hold much hope that Mits will come through as their tech , who requested to be kept in the loop on this will no longer return calls or E-mails. Does anyone have any suggestions or maybe a working Cam T2 with a set of parameters they could send me? This has been an expensive nightmare and I have lost a lot of faith in both Mazak and Mitsubishi.

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mazatrol Cam T2

- Thread starter Drewboy

- Start date

- Replies 15

- Views 9,241

cnctoolcat

Diamond

- Joined

- Sep 18, 2006

- Location

- Abingdon, VA

You can find spare control boards on Ebay, it may be worth a shot to pick some up cheap to try.

The important boards are:

FX701 : main processor board

FX784-8, FX784-9 (or single FX884) : main software boards...very important to function of the machine.

Also one of the boards is for interfacing to front control panel, I can't recall which board it is, but MEAU should know.

Also power supplies are infamous for failing or malfunctioning with such age, so give all them a good checking under load.

MEAU is good, but they have been known to botch repairs. Since they provide a warranty on their work, I would keep hounding them if replacement boards don't work.

Push comes to shove maybe you can find a working T2 machine for a spare, or even an entire control.

Good luck with it, I can't imagine how frustrating it must be.

ToolCat Greg

The important boards are:

FX701 : main processor board

FX784-8, FX784-9 (or single FX884) : main software boards...very important to function of the machine.

Also one of the boards is for interfacing to front control panel, I can't recall which board it is, but MEAU should know.

Also power supplies are infamous for failing or malfunctioning with such age, so give all them a good checking under load.

MEAU is good, but they have been known to botch repairs. Since they provide a warranty on their work, I would keep hounding them if replacement boards don't work.

Push comes to shove maybe you can find a working T2 machine for a spare, or even an entire control.

Good luck with it, I can't imagine how frustrating it must be.

ToolCat Greg

GP Tech

Cast Iron

- Joined

- Jan 23, 2015

- Location

- Port Macquarie, Australia

Looks like FX727 and FX702 goto the control panel.

Do you get any response from the softkeys at all? when on different pages?

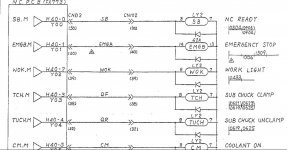

All those output relays reside on the LY2 rail have you confirmed they are getting 24v?

Not defending meau at all but if they said it worked then maybe a wire was damaged or a cable not plugged back in that's hiding and not obvious to see.

Do you get any response from the softkeys at all? when on different pages?

All those output relays reside on the LY2 rail have you confirmed they are getting 24v?

Not defending meau at all but if they said it worked then maybe a wire was damaged or a cable not plugged back in that's hiding and not obvious to see.

GP Tech

Cast Iron

- Joined

- Jan 23, 2015

- Location

- Port Macquarie, Australia

Does the hydraulic pump fire up?

Have you checked the position of the switch (should be up) on the FX715 board?

I just tried my mazak and it does exactly what you are describing if that switch is in the down position.

Have you checked the position of the switch (should be up) on the FX715 board?

I just tried my mazak and it does exactly what you are describing if that switch is in the down position.

Does the hydraulic pump fire up?

Have you checked the position of the switch (should be up) on the FX715 board?

I just tried my mazak and it does exactly what you are describing if that switch is in the down position.

Yes, The switch is in the up position. The control powers up with no alarms and the hydraulic pump is running. The soft keys on the page with turret unclamp, gear selection, coolant, work lamp etc do not work. They operate on other pages but not this one. When the button is selected the back ground on the screen is illuminated for that selection but the control takes no action. Example, if I select work light the selection is lit up but the light will not come on. I am unable to start the machine because the spindle will not start without a gear selection.

wippin' boy

Diamond

- Joined

- Sep 14, 2005

- Location

- il.

you have a qt 15 with a 2 speed gear box?

you have a qt 15 with a 2 speed gear box?

No, however a gear selection of 1 has to be selected before the spindle will run.

GP Tech

Cast Iron

- Joined

- Jan 23, 2015

- Location

- Port Macquarie, Australia

wippin' boy

Diamond

- Joined

- Sep 14, 2005

- Location

- il.

No, however a gear selection of 1 has to be selected before the spindle will run.

seems like that in itself is a parameter issue. has it always been that way?

cwtoyota

Cast Iron

- Joined

- Feb 11, 2010

- Location

- Washington State

seems like that in itself is a parameter issue. has it always been that way?

Yes, when turning the machine on the machine asks for a gear selection. Although there is no gear box we still have to designate a gear. From this point on the selection is retained in memory.

GP Tech

Cast Iron

- Joined

- Jan 23, 2015

- Location

- Port Macquarie, Australia

My T1 is the same

I think Wipps is saying the parameters should be set on a T2 so you don't need to select a gear if there is no gearbox, this suggests that his machine has the wrong parameters.

A quick look through the parameter list shows OP2 bit 5 is the option for a gearless machine. But there may be other parameters that should be set.

I think the parameter list on a T1 is fairly basic compared to a T2.

I think Wipps is saying the parameters should be set on a T2 so you don't need to select a gear if there is no gearbox, this suggests that his machine has the wrong parameters.

A quick look through the parameter list shows OP2 bit 5 is the option for a gearless machine. But there may be other parameters that should be set.

I think the parameter list on a T1 is fairly basic compared to a T2.

I will look at that. Attached is a list of the parameters as they are set right now.

VERY basic

Back to the T2 Saga. I purchased a set of original parameters from Mazak to satisfy the tech I had working on the machine. Installed the original parameters and still had the same issues. Soft Keys not working. The tech I had working on the machine is competent in his own right but apparently this problem was over his head. He gave up and told me I owned an expensive boat anchor. I called Premier Engineering in Atlanta and asked the owner if there was anyone in this world that could fix the machine. Tim told me he had a retired Mazak tech working when he felt like it that might be able to help. Jim the tech contacted me by phone and after a history on the problem he began to troubleshoot the machine with me over the phone. Armed with this info he showed up the next day and a couple hours later determined that an address string in the control was not responding. The control was once again sent to MEAU for repair. A couple days later it was returned in working condition. The trouble was a broken jumper wire on the FX715 board. After 5 months, 3 trips to MEAU and 3 techs we are now running parts. If all seems hopeless, call Premier engineering, they have the best repair service in the world.

cnctoolcat

Diamond

- Joined

- Sep 18, 2006

- Location

- Abingdon, VA

Glad you got it fixed!

MEAU should be ashamed, they should have caught the broken jumper on the first repair!

MEAU generally does good work, and have good phone support. However I have had to return a servo drive or two for a second repair attempt, as they have shown up "dead", even though the paperwork said the drives were repaired correctly.

ToolCat Greg

MEAU should be ashamed, they should have caught the broken jumper on the first repair!

MEAU generally does good work, and have good phone support. However I have had to return a servo drive or two for a second repair attempt, as they have shown up "dead", even though the paperwork said the drives were repaired correctly.

ToolCat Greg

ManualEd

Stainless

- Joined

- Oct 13, 2014

- Location

- Kelowna, Canada

Back to the T2 Saga. I purchased a set of original parameters from Mazak to satisfy the tech I had working on the machine. Installed the original parameters and still had the same issues. Soft Keys not working. The tech I had working on the machine is competent in his own right but apparently this problem was over his head. He gave up and told me I owned an expensive boat anchor. I called Premier Engineering in Atlanta and asked the owner if there was anyone in this world that could fix the machine. Tim told me he had a retired Mazak tech working when he felt like it that might be able to help. Jim the tech contacted me by phone and after a history on the problem he began to troubleshoot the machine with me over the phone. Armed with this info he showed up the next day and a couple hours later determined that an address string in the control was not responding. The control was once again sent to MEAU for repair. A couple days later it was returned in working condition. The trouble was a broken jumper wire on the FX715 board. After 5 months, 3 trips to MEAU and 3 techs we are now running parts. If all seems hopeless, call Premier engineering, they have the best repair service in the world.

Jim R... He didn't happen to be from Canada did he?

Similar threads

- Replies

- 0

- Views

- 136

- Replies

- 7

- Views

- 546