novation1

Plastic

- Joined

- Apr 3, 2017

- Location

- Columbia Station, Ohio USA

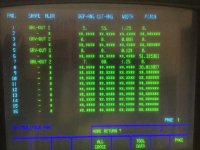

I'm definitely new to Mazatrol programming. I finally got this machine to a condition that it might even be able to make a part. After about 6 months of fixing things. I made this simple program just to see if the machine would run it. When I went to check it things don't look like they should. It seem that it can't write the code. Instead of cutting straight lines it goes on an angle for one pass then just goes everywhere. Just wondering if there is a card that is junk or maybe some parameters not set correctly. I checked all the parameters that I could that I thought may affect this but I'm just learning so I'm hoping one of you smart people would be willing to help me out. Attached are a couple of pictures of the program and the check screen.