So i got just sick enough of the junk coolant delivery setup (whilst burning through inserts cutting 304 because the line kept moving) that I made a solution.

Copied from the plate described earlier (i'm sure there was a photo somewhere too...)

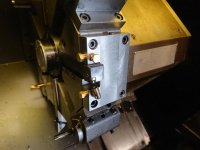

View attachment 221981

View attachment 221982

It routes the coolant to both sides of the tool holder right at the tip, also routes it to the face (mainly because i had to drill there for the internal routing, but could be usefull) All holes are 1/8 bsp threaded for either blanking (i've got some 1/8bsp grub screws on the way to blank it flush) or for simple cheap 90/45* elbows.

As you can see it smashes out a ton of coolant at a good pressure just using a m-m 90 elbow.

View attachment 221983

I've only made 1 so far, but if anyone is interested i'll be making myself another 3 and am happy to pump some out for others if they're interested. Alternately i can hook you up with the CAD/CAM for it as well.

Cheers,

Trav