I've done some searching and it looks like this one may be half beaten to death, but no resolution exactly.

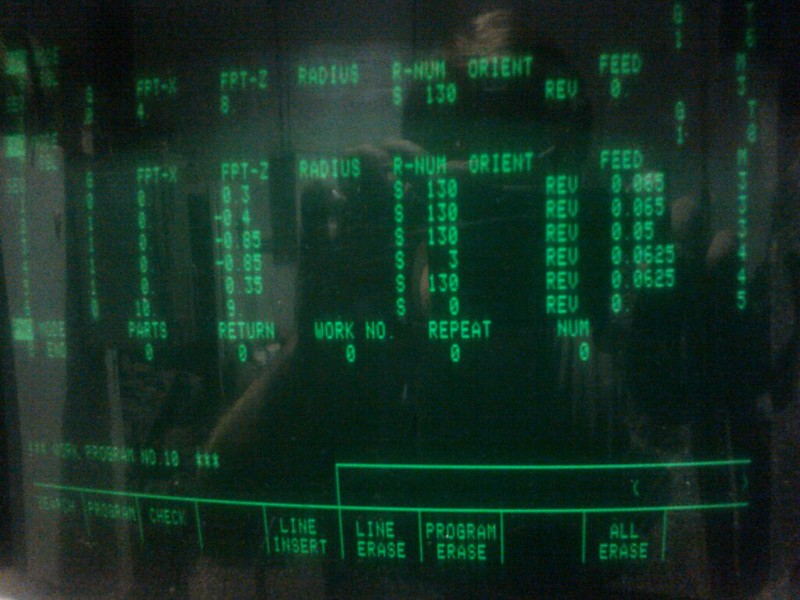

One of the guys I work with is running an '82 vintage Slant 15 with T-1 controls. He's drilling and tapping a hole, wants to option stop so he can put some tapping fluid on the tap after the drill operation. He's been working with this machine for a while so obviously at this point he has work arounds, but he got me involved and now I have to see it through. After the drill operation he returns home and calls an M01. The machine recognizes the M01 (whether the opt stop button is highlighted or not), and stops dead in its tracks. The cycle start button is still glowing along with spindle stop, but he can't continue on with the rest of the program after the option stop sets in, he's gotta reset and start the next process manually.

Any ideas on this? Seems like it should be something simple.

One of the guys I work with is running an '82 vintage Slant 15 with T-1 controls. He's drilling and tapping a hole, wants to option stop so he can put some tapping fluid on the tap after the drill operation. He's been working with this machine for a while so obviously at this point he has work arounds, but he got me involved and now I have to see it through. After the drill operation he returns home and calls an M01. The machine recognizes the M01 (whether the opt stop button is highlighted or not), and stops dead in its tracks. The cycle start button is still glowing along with spindle stop, but he can't continue on with the rest of the program after the option stop sets in, he's gotta reset and start the next process manually.

Any ideas on this? Seems like it should be something simple.