Hello all,

I am in need of some assistance. I have a customer who needs to identify a cone angle on the part shown below at (89.8°) and they have specified that a 2 ball gage should be used to acquire through cmm machine. I am not familiar how the idea of using this method is done through cmm and how to acquire the angle or how to start by going about this. Find diameter of the 2 balls? Have them specially made to sink into the cone and have the cmm probe to acquire the angle?

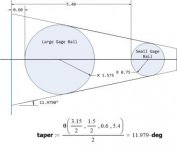

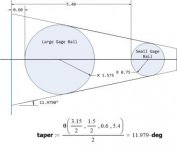

Example I found:

I am in need of some assistance. I have a customer who needs to identify a cone angle on the part shown below at (89.8°) and they have specified that a 2 ball gage should be used to acquire through cmm machine. I am not familiar how the idea of using this method is done through cmm and how to acquire the angle or how to start by going about this. Find diameter of the 2 balls? Have them specially made to sink into the cone and have the cmm probe to acquire the angle?

Example I found: