RLamparter

Hot Rolled

- Joined

- Oct 4, 2008

- Location

- Central PA

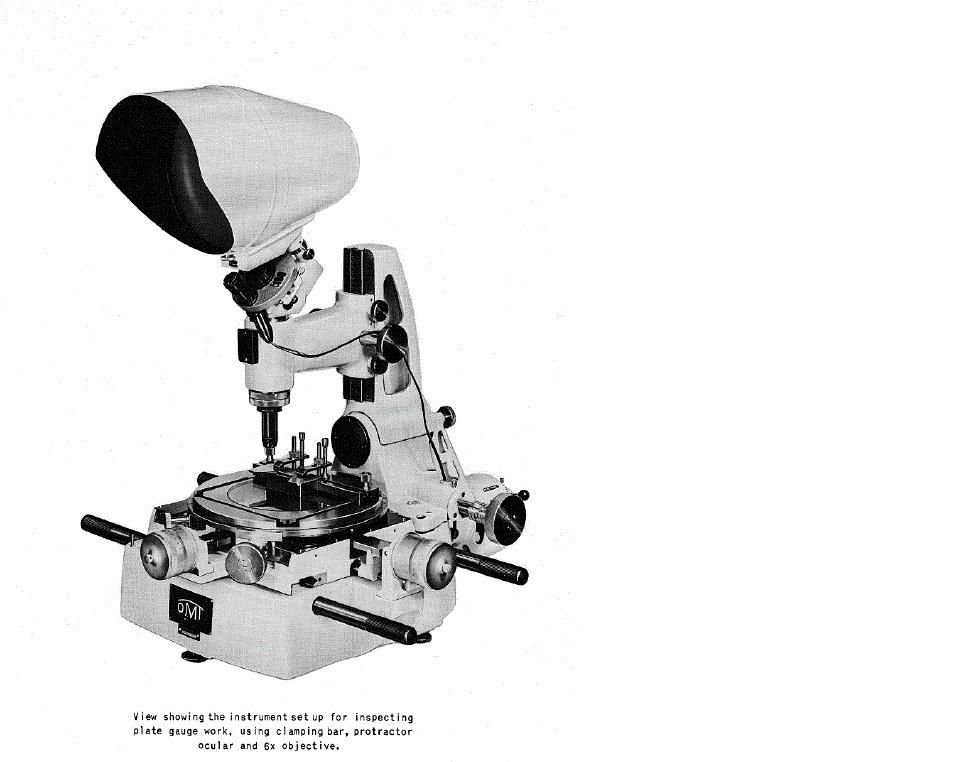

I have an opportunity to pick up a monocular toolmakers microscope at a pretty good price. I have not seen it yet, but the appearance in the photo suggests that it's pretty old. The purpose for acquiring it at all would be to compare the shape of a gear that which needs to have some teeth built up to the single point cutter that I'd use to recut the teeth. I'd also anticipate using it to look at fine detail on small parts, or cutters that I've reground.

I have never used either an optical micrometer nor an optical comparator, so I need some guidance. I know that you can measure angles and overlay drawings of parts on an optical comparator to see if they match. Can you do both of those on a basic toolmakers microscope? What's the difference in usage of a comparator vs a microscope? I have an old binocular dissecting microscope from a school already. Would the toolmakers microscope give me any capability that the dissecting scope doesn't?

I have never used either an optical micrometer nor an optical comparator, so I need some guidance. I know that you can measure angles and overlay drawings of parts on an optical comparator to see if they match. Can you do both of those on a basic toolmakers microscope? What's the difference in usage of a comparator vs a microscope? I have an old binocular dissecting microscope from a school already. Would the toolmakers microscope give me any capability that the dissecting scope doesn't?

and might want to compare it to yours or the Do-All if that one's out there long enough...

and might want to compare it to yours or the Do-All if that one's out there long enough...