I am finishing final assembly of my 10EE and...... Went to bolt the quadrant box to the QCGB and have a clearance issue; the slider gear that selects thread vs. feed input to the QCGB does not want to engage the thread input gear of the quadrant box and does slightly engage the gear train when in the feed position. When I shimmed the quadrant box to sit 40 thousandths higher the gear train meshes nicely.

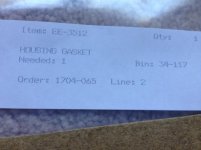

I assume there was a gasket between the quadrant box and the QCGB because I cannot find any shim material/washers in my excess parts bins.

CAVEAT: This is from the Monarch-supplied manual specific to 1942 "Round Dial", piggyback-exciter SN 17120. Your S/N "might" have a different manual, may own such a creature as a "Quadrant box" where mine does not, but I don't think it would affect gasketing - if we are even talking about the same assembly.

"Quadrant", Item #1,

End Gearing, Parts Picture E3? No gaskets in list or on picture. It wasn't even a covered area, my one. later 10EE did have a cover, but there is no threading/feeding selection going on in that area.

Gearbox, Parts Picture E4, has no gaskets in parts list or picture except for item 149, the Oil Gage Housing gasket (AKA "sight glass" to civilians).

OTOH it has a LOT of spacers, bushing, washers, retaining rings in the 154 listed items.

Seems as if one or more of those has gone walkabout, bass-ackwards, or swapped in position and your axial positioning is off. Probably by more than 40 thou, too.

There should be more leeway than 40 thou, just as a matter of ease of production design, cumulative parts tolerances, and expectation of wear.