Jim Mooney

Plastic

- Joined

- Jan 3, 2006

- Location

- Westminster, Md.

I'm fairly new to lathes...about a year of hacking and trying to figure out things on my own, making small masters for pewter castings made in vulcanized rubber molds (for HO trains).

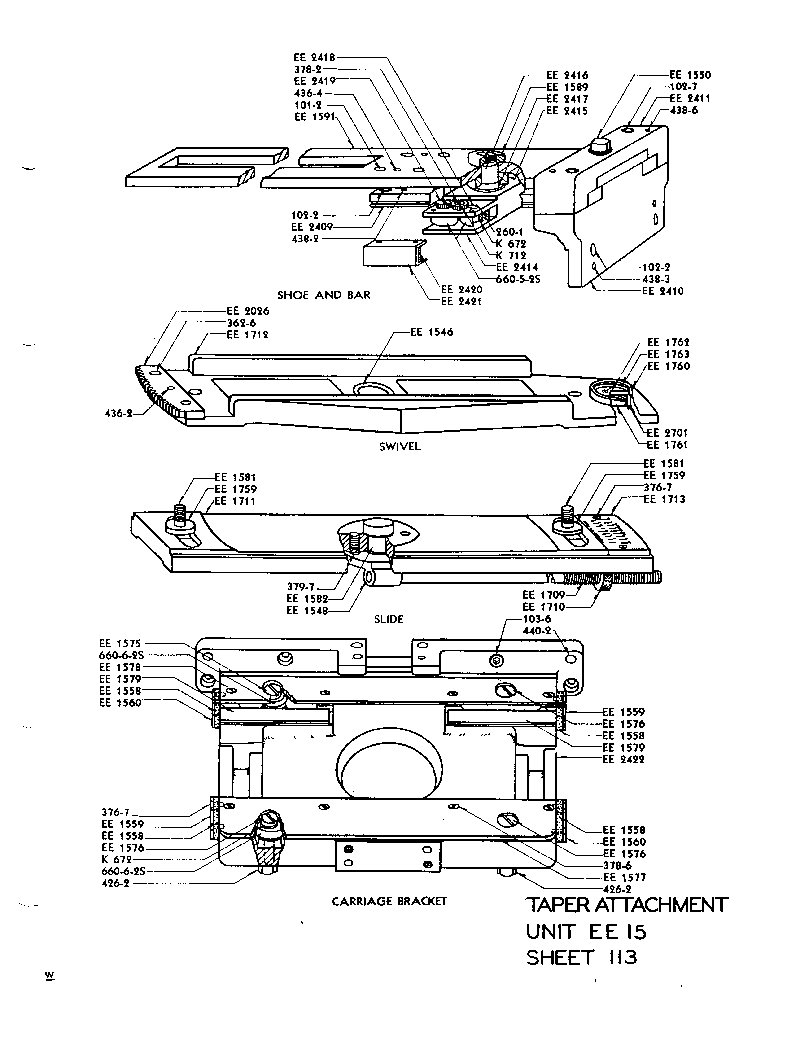

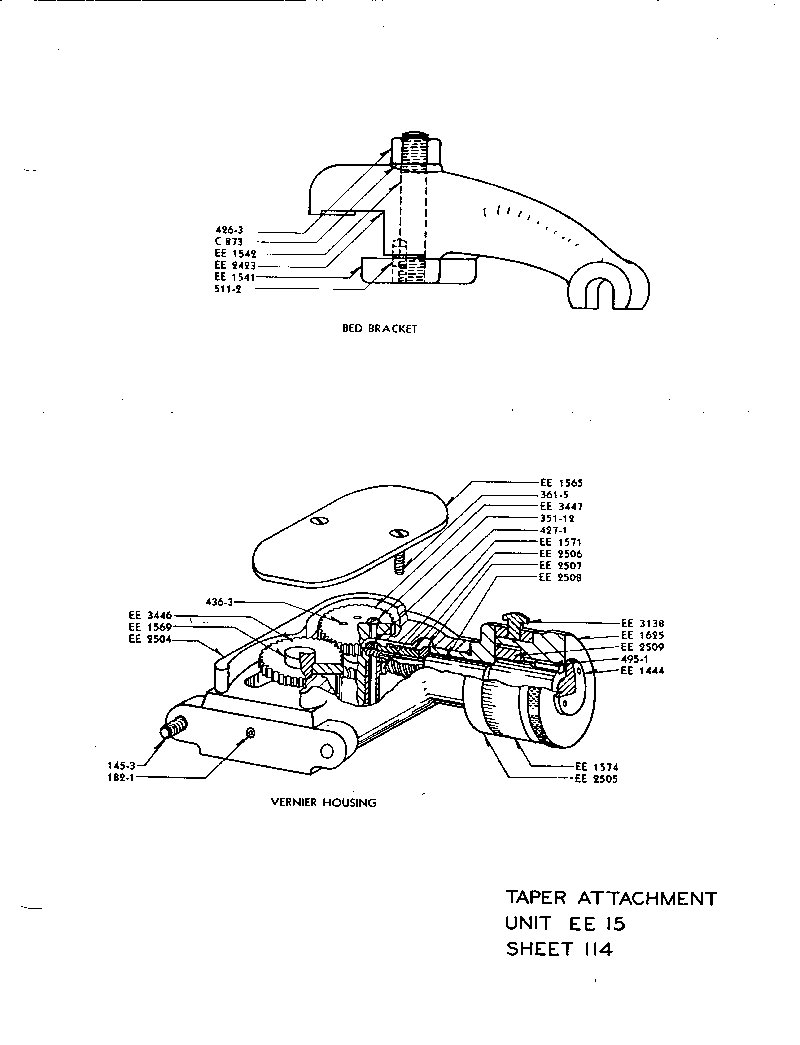

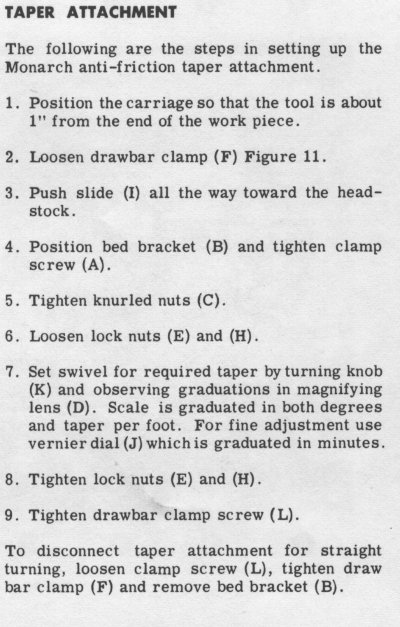

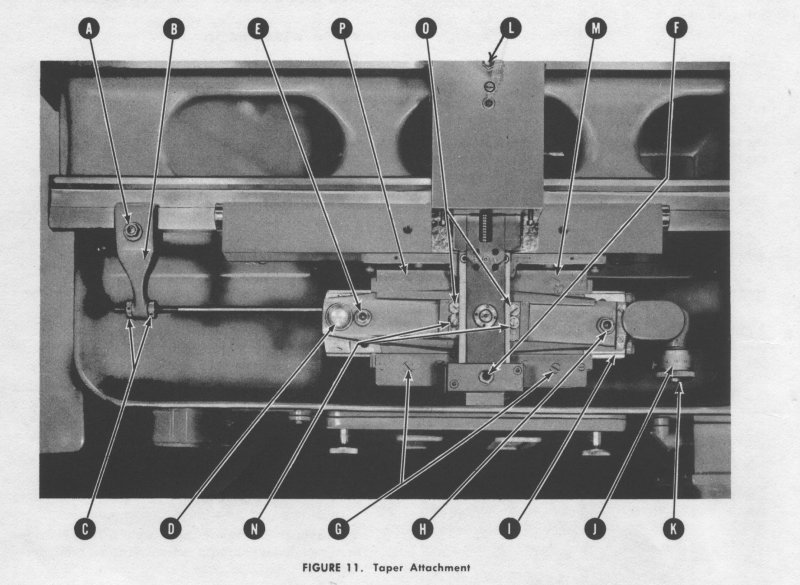

Anyway...we have a 10EE (1952 vintage) at work I have been cleaing up and getting running and I started to clean up the taper attachment. I figured I could figure out how it worked by taking it apart, cleaning up the the dials, and scales, putting it back together, and....well that didn't help...can I get some help explaining how it works? thanks in advance...

Anyway...we have a 10EE (1952 vintage) at work I have been cleaing up and getting running and I started to clean up the taper attachment. I figured I could figure out how it worked by taking it apart, cleaning up the the dials, and scales, putting it back together, and....well that didn't help...can I get some help explaining how it works? thanks in advance...