beckley23

Titanium

- Joined

- Feb 19, 2003

- Location

- Louisville, KY, USA

A while back I got to thinking about the I/M gearbox and the fact that Monarch does it with 2 levers and no change gears. Let's face it, on the EE doing change gears has got to be a royal PITA, but the ability to flip 2 levers and do metric, that's the way to go. I was discussing this with Russ a few days ago, and he asked if I wanted some sheets of the I/M gearbox. He said they weren't to0 good, that they were not high resolution digitals. Send 'em and I'll see what I can do with them. A couple hours later I had them and was able to blow them up on my computerand see the details. I made some copies, 5 sheets, and took them to the blueprint shop and they were able to blow them up 300%, the lines are line fuzzy, but my "old" eyes were able to make things out. After a couple days of screwing around with the metric change gears calculations for my CK, I got around to the EE prints.

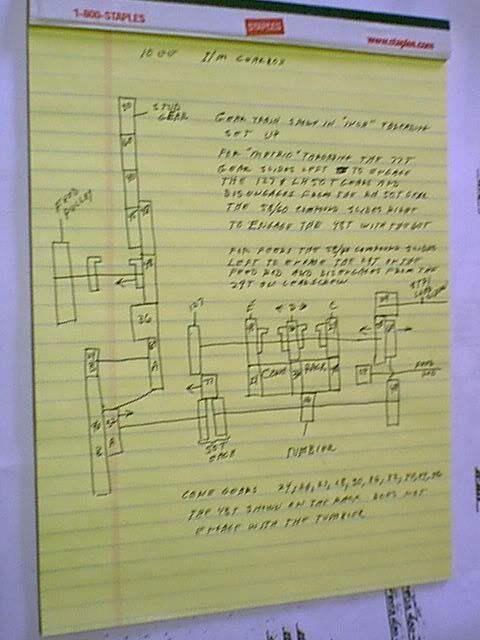

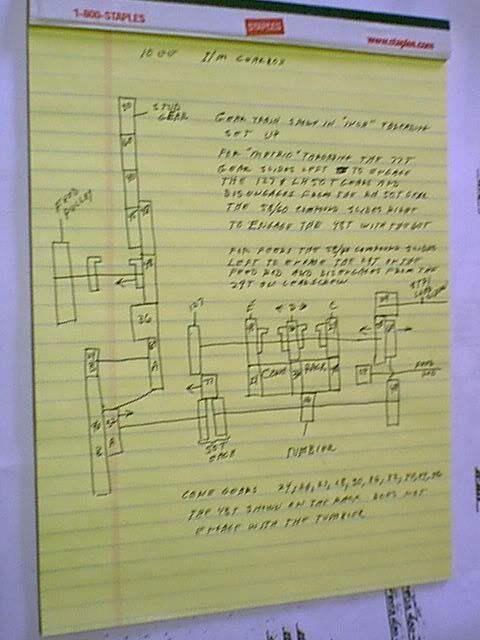

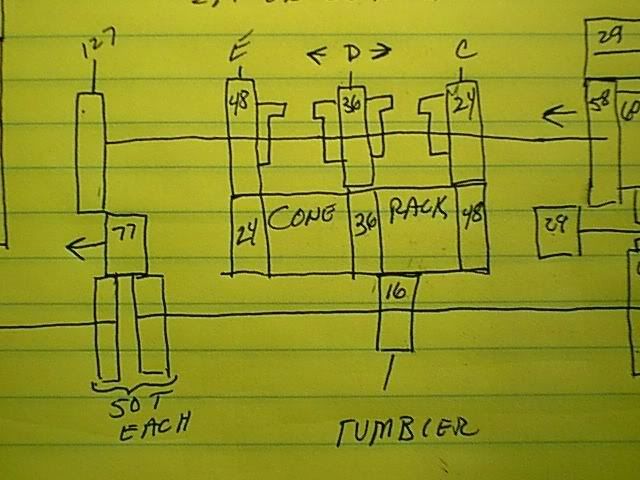

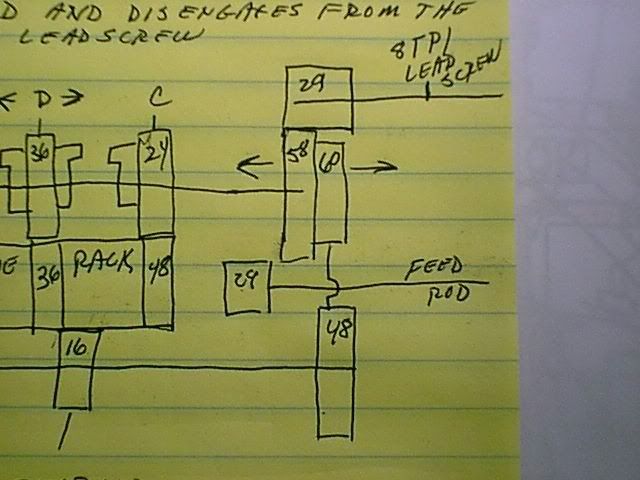

Here's my interpretation of the parts sheets. The calculations do check out.

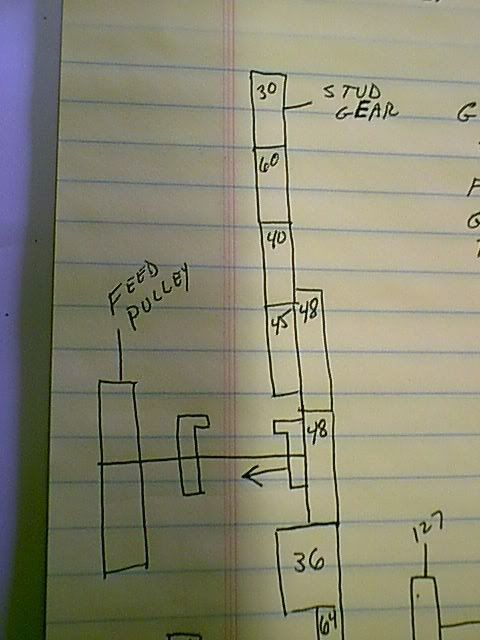

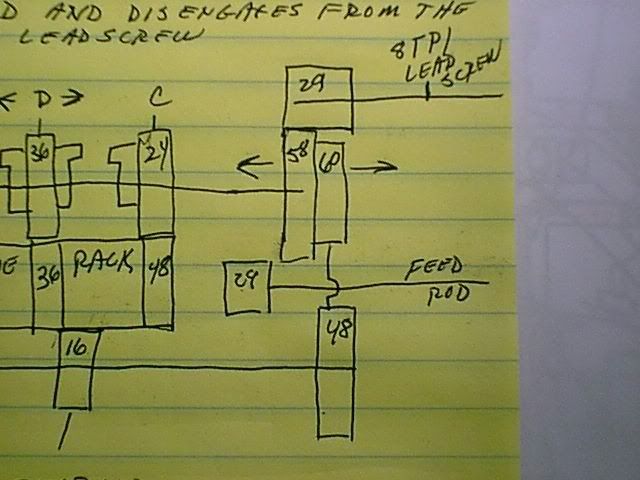

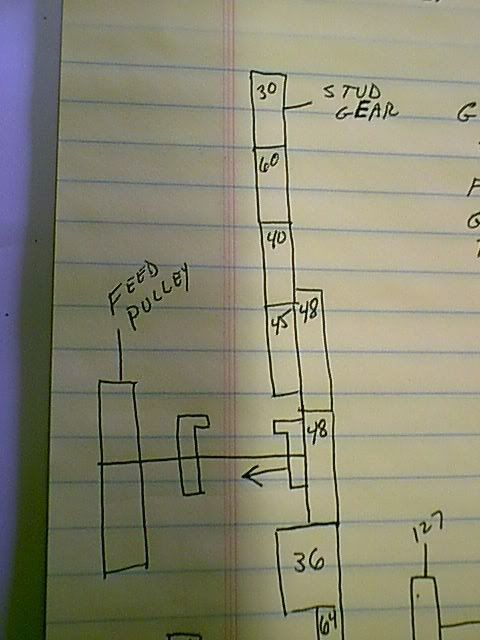

The gear train is shown in the inch mode.

For metric threading the 77T gear slides to the left, that's the shifter on the left side of the gearbox, to engage the 127 and LH 50 T gears and disengage from the RH 50T gear. On the right hand side the 58/60 compound gear slides to the right to engage the 48 T with the 60T gear. This compound gear has 3 positions, to the left as shown it disengages the 29T gear on the leadscrew and engages the 29T gear on the feed rod, in the center it engages the 29T gear on the leadscrew and to the right has been previously described. This is the feed, inch, metric shifter on the right hand side of the gearbox.

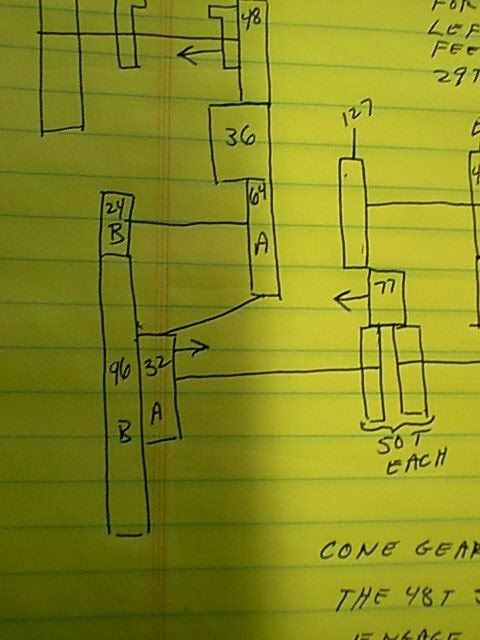

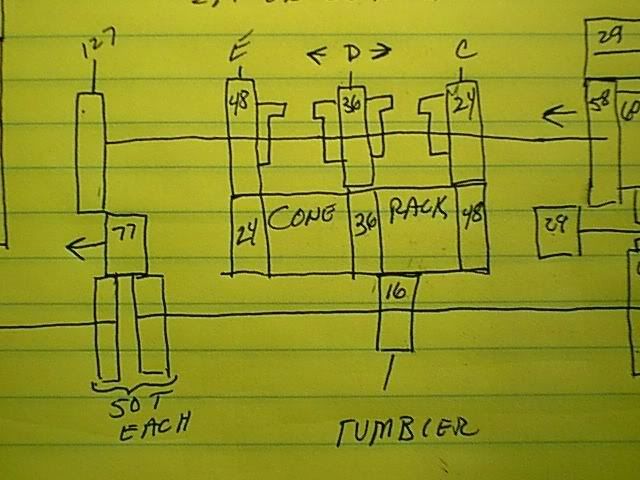

The cone gears are 24, 26, 27, 28, 30, 36, 32, 40, 44, and 46. The 48T gear on the rack is the C position of the C-D-E shifter.

The gearbox itself is divided into 3 sections and I think they are pretty obvious. The center compartment contains the C-D-E and cone rack gears, the other 2 are on each side.

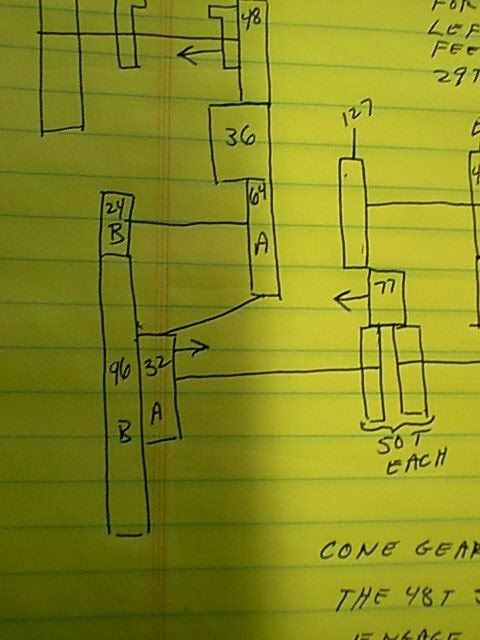

One of the problems in figureing out the gearbox on the parts sheets, and this is where the fuzziness of the exploded caused a bit of trouble is the 64A shiftgear and the 127 are on one shaft, or so it initially appears. They are separate rotations, it's just the 64 has an extension that goes into the 127, for support, I assume. Also the part sheet shows a shaft spacer on the left side preventing a shift. This spacer had to go, and so said a notation off to the side, at least that's the way I interpreted it.

There were a couple of other issues, mostly caused by the fuzziness of the exploded sheets, and I had to check the exploded views on the computer where the lines are much sharper.

There are at least 2 Pitch Diameters used in the gearbox. All the gears are 16DP, except the 24 & 96 A shift gears are 20DP, and I believe all the metric conversion gears are also 20DP.

Hope you can read my sketches, this is about as good as it gets with me.

Harry

Here's my interpretation of the parts sheets. The calculations do check out.

The gear train is shown in the inch mode.

For metric threading the 77T gear slides to the left, that's the shifter on the left side of the gearbox, to engage the 127 and LH 50 T gears and disengage from the RH 50T gear. On the right hand side the 58/60 compound gear slides to the right to engage the 48 T with the 60T gear. This compound gear has 3 positions, to the left as shown it disengages the 29T gear on the leadscrew and engages the 29T gear on the feed rod, in the center it engages the 29T gear on the leadscrew and to the right has been previously described. This is the feed, inch, metric shifter on the right hand side of the gearbox.

The cone gears are 24, 26, 27, 28, 30, 36, 32, 40, 44, and 46. The 48T gear on the rack is the C position of the C-D-E shifter.

The gearbox itself is divided into 3 sections and I think they are pretty obvious. The center compartment contains the C-D-E and cone rack gears, the other 2 are on each side.

One of the problems in figureing out the gearbox on the parts sheets, and this is where the fuzziness of the exploded caused a bit of trouble is the 64A shiftgear and the 127 are on one shaft, or so it initially appears. They are separate rotations, it's just the 64 has an extension that goes into the 127, for support, I assume. Also the part sheet shows a shaft spacer on the left side preventing a shift. This spacer had to go, and so said a notation off to the side, at least that's the way I interpreted it.

There were a couple of other issues, mostly caused by the fuzziness of the exploded sheets, and I had to check the exploded views on the computer where the lines are much sharper.

There are at least 2 Pitch Diameters used in the gearbox. All the gears are 16DP, except the 24 & 96 A shift gears are 20DP, and I believe all the metric conversion gears are also 20DP.

Hope you can read my sketches, this is about as good as it gets with me.

Harry