Scrambled1981

Plastic

- Joined

- Aug 17, 2012

- Location

- Paris, ky

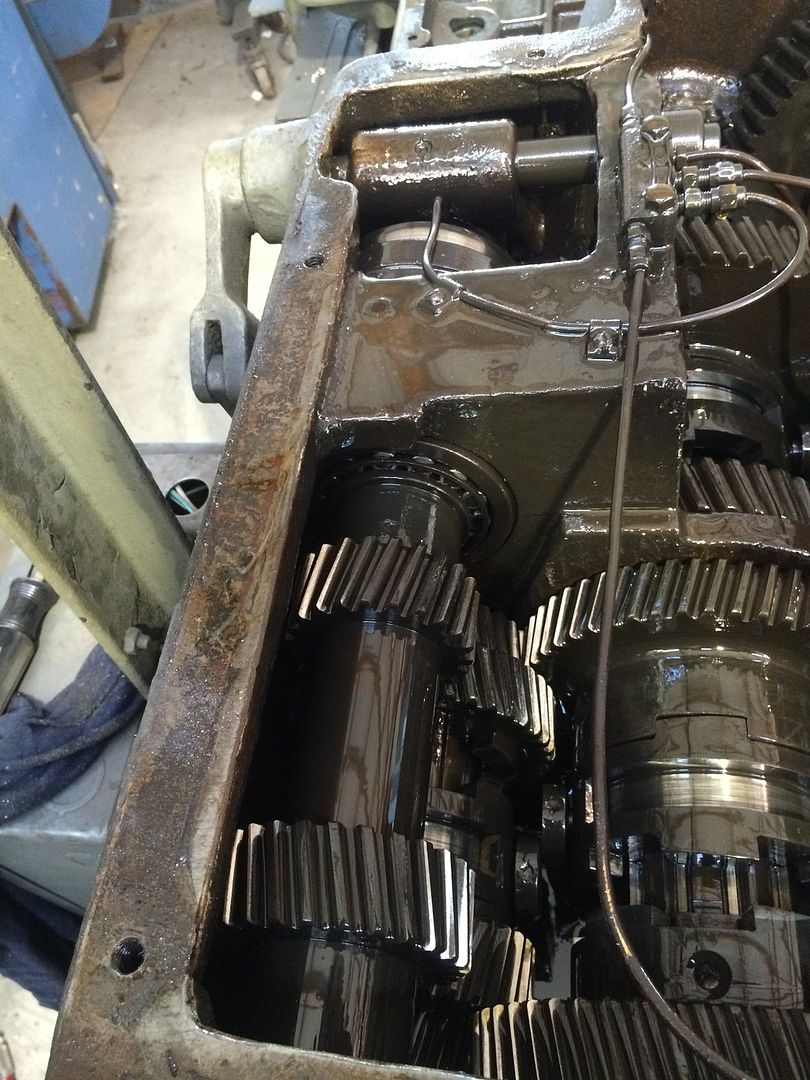

I got this lathe about a year ago, and it has been sitting in my shop collecting clutter on and around it.

When I got it, the motor contactor was missing. I am in the process of getting it working. I direct wired a plug to the motor, and it runs really smooth.

The ID plate was removed from the front for some reason. I am having a hard time ID the lathe. Any ideas?

So I have a few question if anyone has the time.

1- any idea of the model #? the distance from the center of the chuck to the top of the way is 10 inches. The distance from the end of the chuck to the end of the tail stock is 54 inches.

2- does the contactor need to be a standard contactor with overload, or a reversing contactor with an overload?

3- can I reverse direction of the chuck for using a die? either mechanical or electrical?

anything I need to look at before I start playing with it? What type of oil for the head?

thanks

Steve

When I got it, the motor contactor was missing. I am in the process of getting it working. I direct wired a plug to the motor, and it runs really smooth.

The ID plate was removed from the front for some reason. I am having a hard time ID the lathe. Any ideas?

So I have a few question if anyone has the time.

1- any idea of the model #? the distance from the center of the chuck to the top of the way is 10 inches. The distance from the end of the chuck to the end of the tail stock is 54 inches.

2- does the contactor need to be a standard contactor with overload, or a reversing contactor with an overload?

3- can I reverse direction of the chuck for using a die? either mechanical or electrical?

anything I need to look at before I start playing with it? What type of oil for the head?

thanks

Steve