timewarp

Aluminum

- Joined

- Feb 4, 2005

- Location

- Vancouver Island

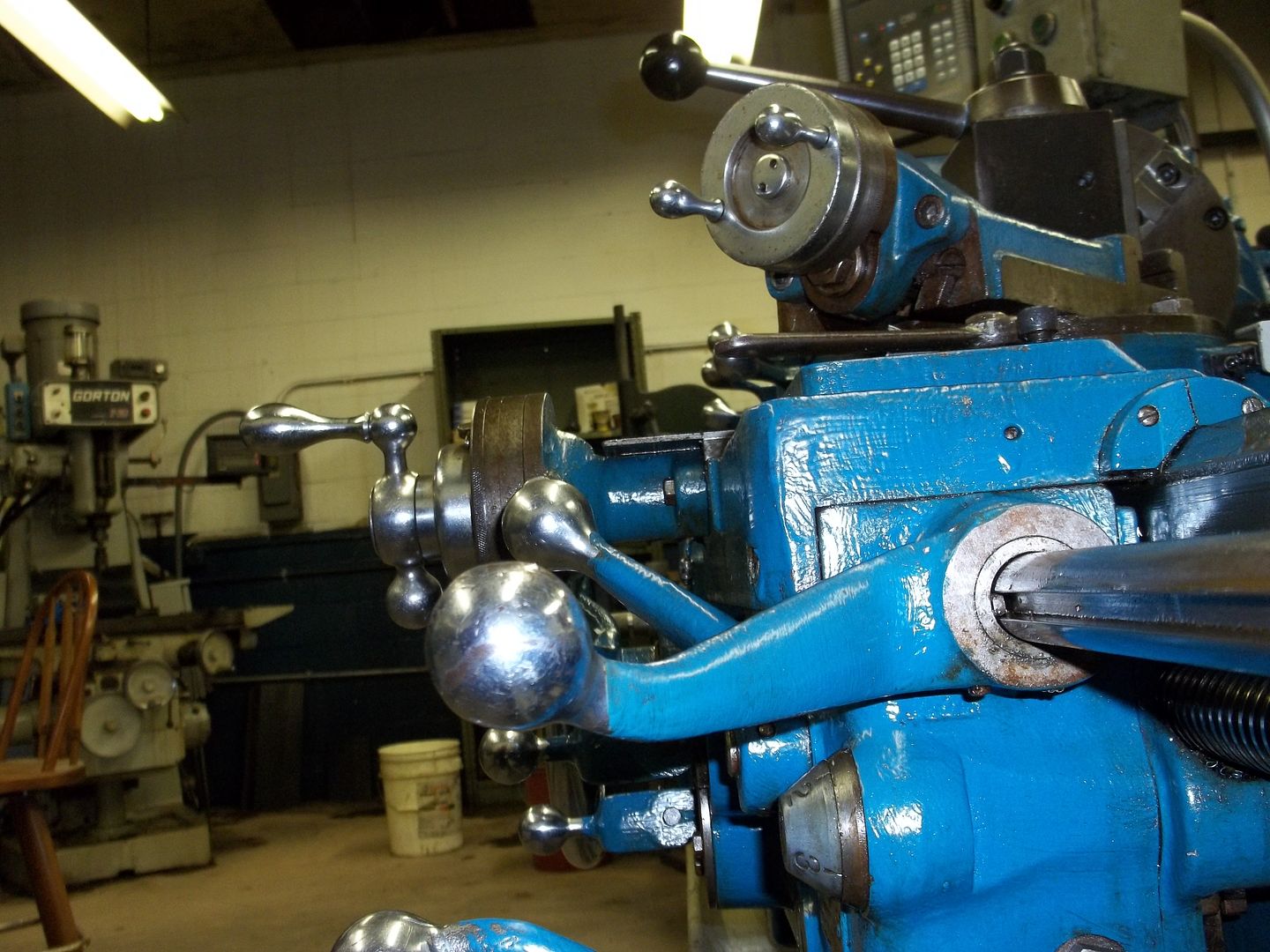

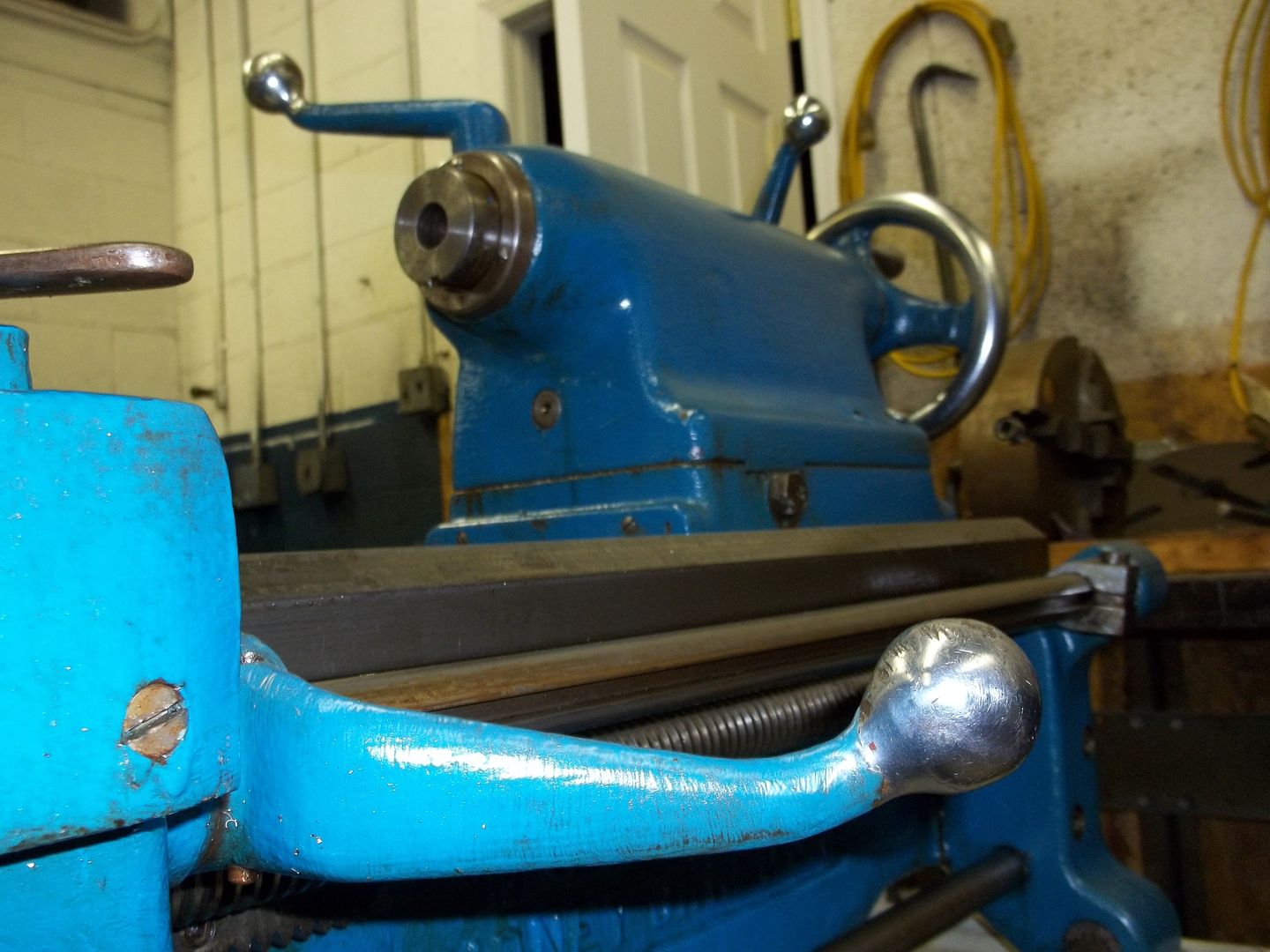

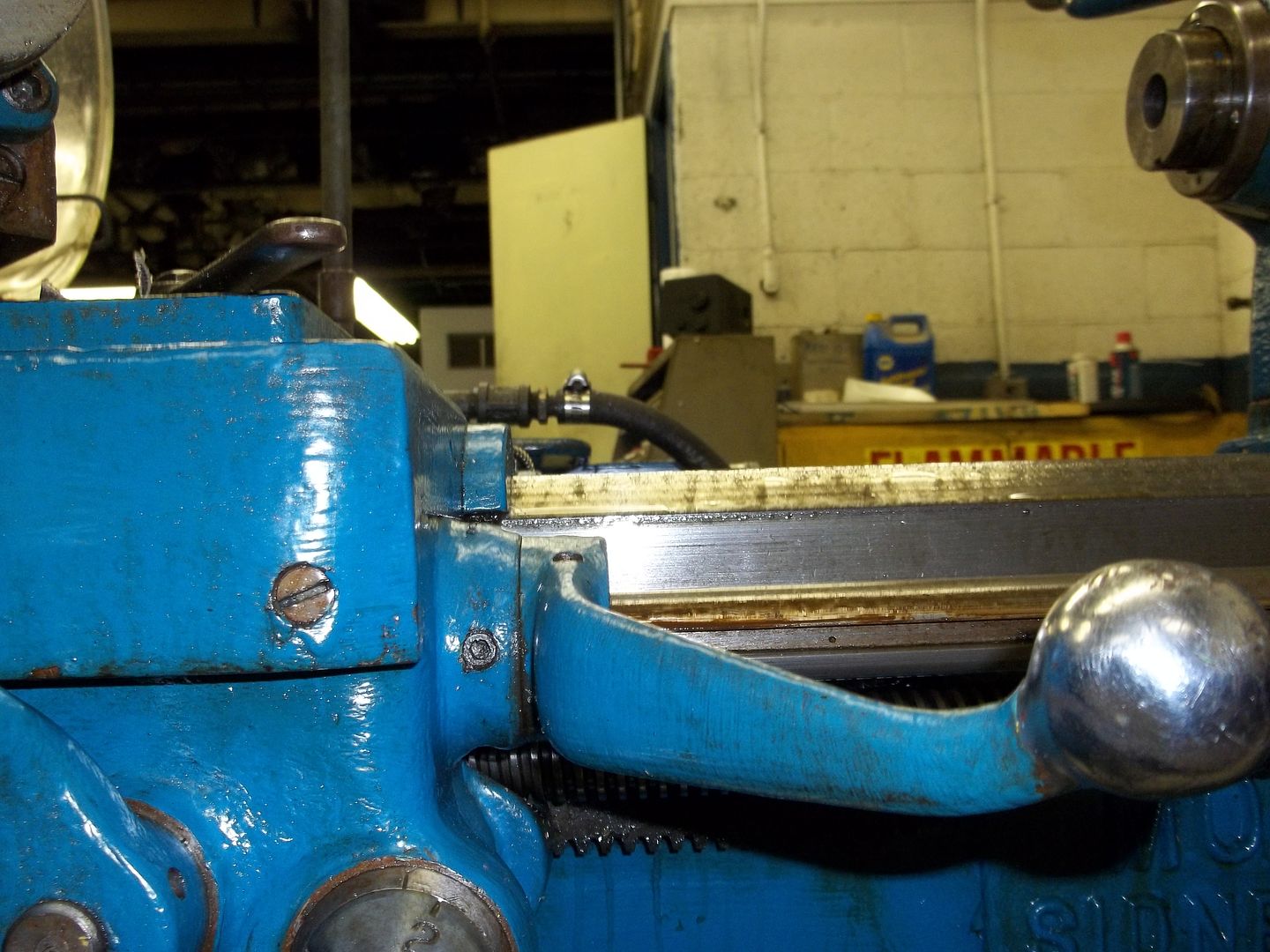

Hi, Just got my first Monarch lathe - a 12ck! It seems to be in very good condition for a 1944 model. I promise I will post some photos in a few days. I have a few questions about running a lathe like this - its not my first lathe but there are more levers than i'm used to!

I remember a post I read where someone (johnoder?) described basic operation, but I can't find it now. If anyone can find this I'd like to print it out and add it to my manual.

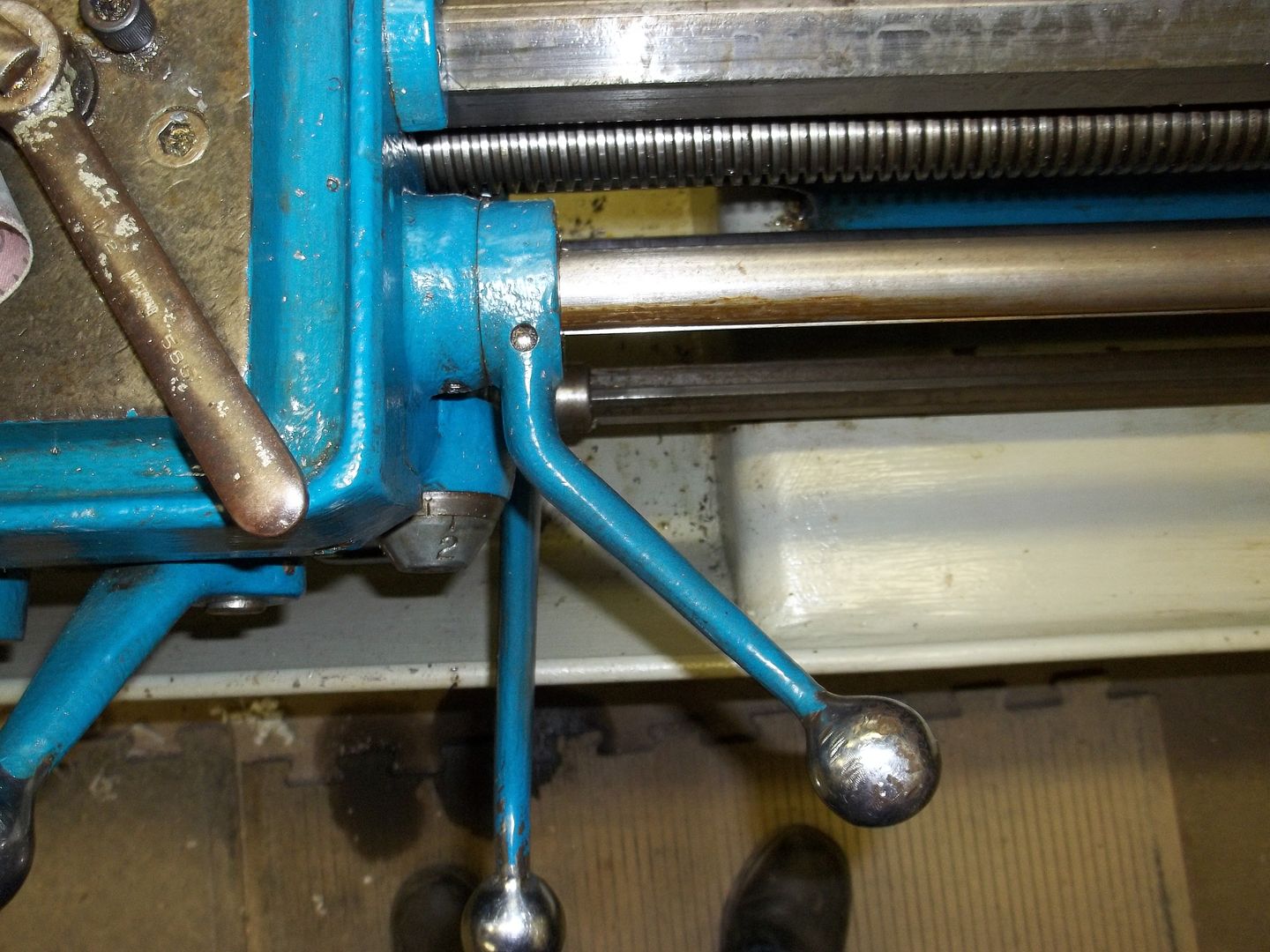

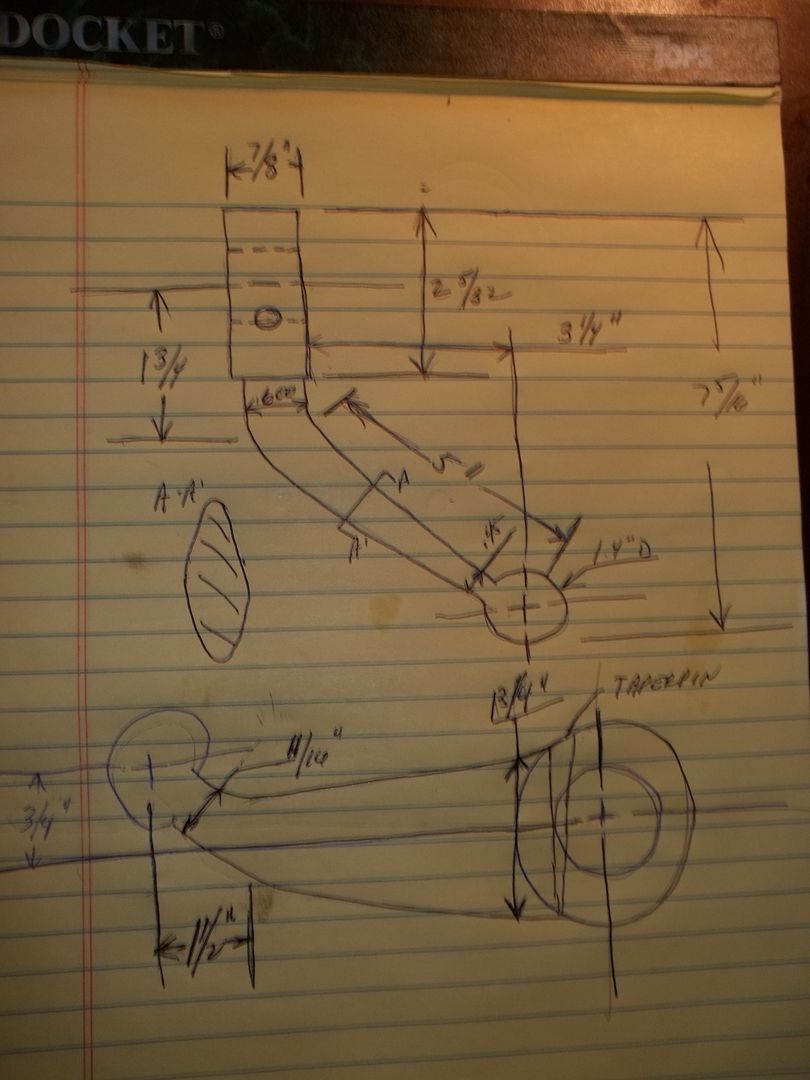

Also is there a description of threading as it pertains to the Monarch? The cross slide has a threading stop mechanism. not sure how it works though!

Yes I am jumping the gun as I don't have it moved into position or have power to it yet.

Happy to have joined the Monarch owners club!

Paul

I remember a post I read where someone (johnoder?) described basic operation, but I can't find it now. If anyone can find this I'd like to print it out and add it to my manual.

Also is there a description of threading as it pertains to the Monarch? The cross slide has a threading stop mechanism. not sure how it works though!

Yes I am jumping the gun as I don't have it moved into position or have power to it yet.

Happy to have joined the Monarch owners club!

Paul