Yep it is smaller than the large one I have.

View attachment 197211

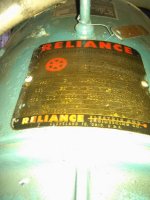

The one I have here, 1150-4000 RPM, has a splined shaft, and DID have a GE tachogenerator on the other end. Good motors. Better at high-RPM than the large frame - check the dataplates.

Downside is that it has but - IIRC - 15 ft/lb or so of torque at base RPM and below vs around 23 ft/lb for the older 690-2400 RPM motor. Hence the move to 5 HP DC, next generation.

The small frame 3 HP is accordingly the most likely to be dependent of all 10EE except VFD conversions on having a good gearbox.

Ironically, the original large frame 'could have' probably done just fine with no gearbox. Didn't happen because the sort of DC Drive and feedback or tacho needed to power them with stable regulation at really low RPM did not enter MMT's environment until advent of the "Monarch Sidney" 3-Phase-only DC Drive & siblings. Those two components were never matched to each other AFAIK. More-recent Parker-SSD drives can also deliver seriously low RPM in direct-drive, so long as equipped with a rather massive ripple filter choke.

Around the era of the Monarch-Sidney, DC motor costs had begun their climb into the $11,000 - $12,000 MSRP high altitudes, so VFD came next instead of further improved DC.

So long as we already HAVE the costly DC motors, as Everettengineer pointed out, the availability so many years on, of decent Solid State DC Drives has given us the option to 'backfill' that gap at far more realistic costs vs VFD + new/used 3-P motor and adaptation machining work.

That said, if you can find decent tubes, straight restoral to 'as-built' should be cheaper and less labour-intensive yet.