rakort

Hot Rolled

- Joined

- Apr 27, 2011

- Location

- Central Wisconsin

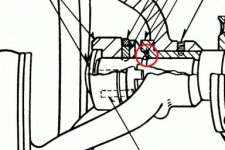

So couple of questions regarding some details of the handwheel input shaft assembly.

On the input "clutch" hub there is a pin held in by a circle clip which would almost act as a detent to slip the clutch collar/hub in and out to enable or disable the handwheel clutch operation.

The detents in the shaft seem minimal or not intentional. The clutch hub is knurled implying there is some intent to shift it in or out so these things don't go together.

Also, is the purpose of the set screw in the hub on the handwheel to simply secure the pressed in clutch hub? Seems redundant to what seems to be an otherwise pressed in fit.

thoughts?

On the input "clutch" hub there is a pin held in by a circle clip which would almost act as a detent to slip the clutch collar/hub in and out to enable or disable the handwheel clutch operation.

The detents in the shaft seem minimal or not intentional. The clutch hub is knurled implying there is some intent to shift it in or out so these things don't go together.

Also, is the purpose of the set screw in the hub on the handwheel to simply secure the pressed in clutch hub? Seems redundant to what seems to be an otherwise pressed in fit.

thoughts?