How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wanting to buy a 10e radius/spherical/ball turning attachment

- Thread starter Tannewitz

- Start date

- Replies 50

- Views 16,433

bsg

Titanium

- Joined

- Jan 17, 2003

- Location

- Imlay City, Michigan

John,

I don't think Monarch actually made a spherical cutting attachment for the 10ee.

Holdrige would probably be your best bet.

Do a Google search, there are a lot of different options available.

Good luck.

Kevin

1935Ron

Aluminum

- Joined

- May 3, 2009

- Location

- New Jersey USA

John,

I don't think Monarch actually made a spherical cutting attachment for the 10ee.

Holdrige would probably be your best bet.

Do a Google search, there are a lot of different options available.

Good luck.

Kevin

ther is a boat load on e-bay>>

holdridge in Manufacturing & Metalworking | eBay

rke[pler

Diamond

- Joined

- Feb 19, 2002

- Location

- Peralta, NM USA

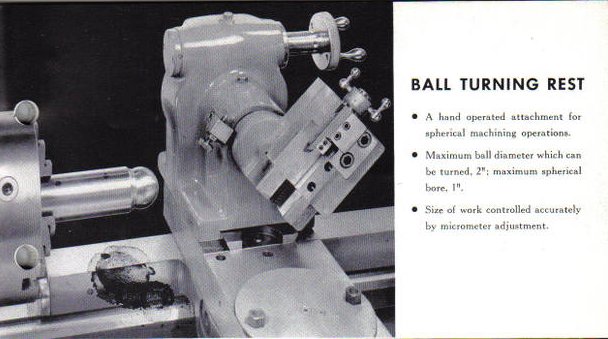

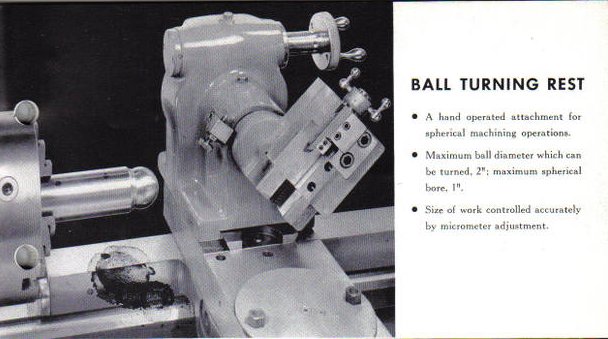

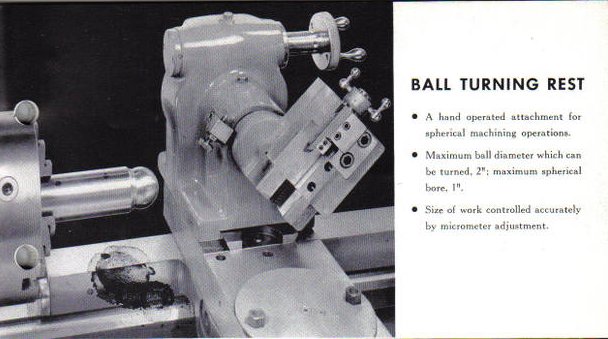

I think Monarch did, or at least made a prototype. From a 1957 brochure:

But I've never seen one in the wild.

The Holdridge 3 is the right size for the 10EE with the normal compound.

But I've never seen one in the wild.

The Holdridge 3 is the right size for the 10EE with the normal compound.

It is my understanding that Monarch made one as an option. I have seen one that I understood to be OEM Monarch.... unlike any Holdridge I have ever seen (which I have).

Will someone more knowledgeable add to this ....even an image or scan from a catalog/manual,etc.

Just saw the post from rke[pler...that's it! Thanks for the posting....maybe someone has one and did not know what it was until now.

Thanks, John

Will someone more knowledgeable add to this ....even an image or scan from a catalog/manual,etc.

Just saw the post from rke[pler...that's it! Thanks for the posting....maybe someone has one and did not know what it was until now.

Thanks, John

oldster

Hot Rolled

- Joined

- Jun 20, 2010

- Location

- santa cruz, CA

Thanks for the image! As always, Monarch recognized the problem and nailed it!

The Holdridge system (regardless of size) is nothing more than a harmonic tuning fork!

Because it is so flimsy, you cannot take serious cuts, the older versions did not use inserts, and so you had to grind and reset each time you had to sharpen the tool. I finally got so pissed off that I made my own, and managed to solve those problems.

I will ask the guy I sold it to (with the lathe) to take pictures.

What I did was to make a pair of brass "V" grooves that rode on the ways of the lathe. They were supported by a cross bar made of 2" square steel. The outer "C" of the cutter frame was adjustable to fit snugly on top of the cross bar.

This gave me a solid footing. From there, it was easy to build the rest.

I was able to go from a 1" dia to an 8" dia both internal and external using the same fixture, and peel off .050 cuts, turning the chip stream blue!

I don't mean to tease, and I promise the images soon.

Lee (the saw guy)

The Holdridge system (regardless of size) is nothing more than a harmonic tuning fork!

Because it is so flimsy, you cannot take serious cuts, the older versions did not use inserts, and so you had to grind and reset each time you had to sharpen the tool. I finally got so pissed off that I made my own, and managed to solve those problems.

I will ask the guy I sold it to (with the lathe) to take pictures.

What I did was to make a pair of brass "V" grooves that rode on the ways of the lathe. They were supported by a cross bar made of 2" square steel. The outer "C" of the cutter frame was adjustable to fit snugly on top of the cross bar.

This gave me a solid footing. From there, it was easy to build the rest.

I was able to go from a 1" dia to an 8" dia both internal and external using the same fixture, and peel off .050 cuts, turning the chip stream blue!

I don't mean to tease, and I promise the images soon.

Lee (the saw guy)

Holy Shitskies! That Monarch picture looks crazy (awesome)!

That said, I have a couple of questions:

1) What is the significance of the vertical orientation of the cutter rotation? Seems like most other radius attachments I have seen operate in the horizontal plane (assuming the lathe wasn't tipped over )

)

2) That tool would be difficult to make a hemispherical groove partway into a workpiece, wouldn't it? Maybe I'm missing something

That said, I have a couple of questions:

1) What is the significance of the vertical orientation of the cutter rotation? Seems like most other radius attachments I have seen operate in the horizontal plane (assuming the lathe wasn't tipped over

)

)2) That tool would be difficult to make a hemispherical groove partway into a workpiece, wouldn't it? Maybe I'm missing something

DaveE907

Titanium

- Joined

- Sep 18, 2007

- Location

- Spanish Springs, NV

That Monarch accessory was on center. It's rotational axis was horizontal at a right angle to the spindle.

1) There is no significance in your vernacular vertical or horizontal orientation of the axis of rotation of the sweeping cutter. It would do fine at 45 degrees from horizontal or at any other orientation as long as it's at an exact right angle to the spindle and on exactly on center.

2) You're on point, that tool nor can any other can make a hemispherical groove, they don't exist. However a generated radius bottom groove into a work piece is another story. That Monarch accessory can't do that without modification.

No one would do such work today in a profit driven situation with real competition.

1) There is no significance in your vernacular vertical or horizontal orientation of the axis of rotation of the sweeping cutter. It would do fine at 45 degrees from horizontal or at any other orientation as long as it's at an exact right angle to the spindle and on exactly on center.

2) You're on point, that tool nor can any other can make a hemispherical groove, they don't exist. However a generated radius bottom groove into a work piece is another story. That Monarch accessory can't do that without modification.

No one would do such work today in a profit driven situation with real competition.

bsg

Titanium

- Joined

- Jan 17, 2003

- Location

- Imlay City, Michigan

I think Monarch did, or at least made a prototype. From a 1957 brochure:

But I've never seen one in the wild.

The Holdridge 3 is the right size for the 10EE with the normal compound.

Well I stand corrected!

Thanks for the picture by the way.

I have never seen anything like that either in photos or in real life, if there were any made it had to be so few it definitely is unobtanium.

I remember someone on the PM forum a while back post pictures of his gear drive ball turning attachment, it looked like it would be a lot better than the Holdridge.

Maybe he will chime in and post some info on it.

Kevin

wfrancis

Aluminum

- Joined

- Apr 18, 2012

- Location

- San Francisco, USA

This video has what's looks to be a genuine Monarch attachment, based on the catalog photos shown.

Monarch 10EE Toolroom Lathe m/c 315586 - YouTube

Were the dovetails on the far side of the cross slide an option or standard after a particular year?

Monarch 10EE Toolroom Lathe m/c 315586 - YouTube

Were the dovetails on the far side of the cross slide an option or standard after a particular year?

bsg

Titanium

- Joined

- Jan 17, 2003

- Location

- Imlay City, Michigan

This video has what's looks to be a genuine Monarch attachment, based on the catalog photos shown.

Monarch 10EE Toolroom Lathe m/c 315586 - YouTube

Were the dovetails on the far side of the cross slide an option or standard after a particular year?

Thanks for the video link!

OMG I want one.

Now something else I have to keep an eye out for, damn just when I thought I was making progress.

Hello, my name is Kevin and I'm a tool junkie!

I'm going to go take my meds now.

Thanks Tannewitz, see what you started!

Kevin

That Monarch accessory was on center. It's rotational axis was horizontal at a right angle to the spindle.

1) There is no significance in your vernacular vertical or horizontal orientation of the axis of rotation of the sweeping cutter. It would do fine at 45 degrees from horizontal or at any other orientation as long as it's at an exact right angle to the spindle and on exactly on center.

2) You're on point, that tool nor can any other can make a hemispherical groove, they don't exist. However a generated radius bottom groove into a work piece is another story. That Monarch accessory can't do that without modification.

No one would do such work today in a profit driven situation with real competition.

Perhaps my use of the term "hemispherical groove" is not correct. I'm guessing that your phrasing is probably the same as what I picture - a groove running around the workpiece whose shape is that of half of a circle. That tool certainly does exist, because I made one!

So I wonder why the vertical orientation - space requirements, some aspect of rigidity with respect to the ways (such as with a rear mounted parting tool), being able to leave it attached and use the normal toolpost/compound?

I couldn't care less if it competes with modern machinery - it was from 1957! That doesn't make it any less cool or interesting.

Wfrancis,

I saw the YouTube video earlier and had already called the company, a machinery dealer, who posted the YouTube video. They sold the lathe sometime back. They are trying to connect me with the purchaser to see if the ball turing attachment might be surplus to their needs.

thanks, John

I saw the YouTube video earlier and had already called the company, a machinery dealer, who posted the YouTube video. They sold the lathe sometime back. They are trying to connect me with the purchaser to see if the ball turing attachment might be surplus to their needs.

thanks, John

Steve in SoCal

Titanium

- Joined

- Oct 17, 2006

The lathe in the video was purchased by a guy in Woodland Hills, I asked him about the attachment years ago to no avail. I did get a message that he was considering selling the machine complete early this year, it may still be for sale. The price was pretty high around 11~12K IIRC

Steve

Steve

ORAGRAG

Aluminum

- Joined

- Oct 29, 2002

- Location

- Lino Lakes, Minnesota

ORAGRAG

Aluminum

- Joined

- Oct 29, 2002

- Location

- Lino Lakes, Minnesota

Ok so now we all will want to know details - where did you find it? Ballpark on what you paid?

Post a video when you use it - seems like you may be the only one on the list with one of these.

Paul

I got a hold of the fellow from Woodland Hills and got him to agree to sell it off of his machine. I am bit embarrassed to say how much I paid. Once I found it I just had to have it.

bsg

Titanium

- Joined

- Jan 17, 2003

- Location

- Imlay City, Michigan

How embarrassed are you?

You should not be embarrassed, I have paid way more for tooling on some machines than the actual machine purchase price!

Please post some pics when you get it painted to match your machine.

BTW that's a great find and congrats.

Kevin

You should not be embarrassed, I have paid way more for tooling on some machines than the actual machine purchase price!

Please post some pics when you get it painted to match your machine.

BTW that's a great find and congrats.

Kevin

Similar threads

- Replies

- 3

- Views

- 170

- Replies

- 6

- Views

- 948

- Replies

- 15

- Views

- 960

- Replies

- 5

- Views

- 803