I recently bought a lathe to learn on and didn't mind getting something smaller than I really wanted at the time. Now that I have it and have it setup I'm wondering what would be good to turn on it. I will admit getting into low and high gear looks like a pain in the ass because it's a linked vbelt and I don't see any way of changing speeds without break the belt and reassembling it.

As far as material goes I would like to be able to work with cast iron, steel, and brass. Brass is easy so I imagine that won't be an issue. I do have some carbid cutters. I just wonder with the 3/4 HP motor how well the machine will do for these harder materials. I guess I won't be taking deep cuts.

Even though it is a little smaller than I wanted it is a nice lathe. The previous owner must have rebuilt it because the bed ways looked like they were recently put through a shaper and flaked.

Updates:

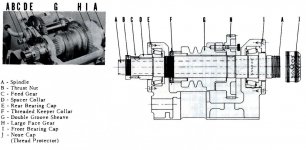

It's a 10.125" swing (Series XL) with 1" collet capacity.

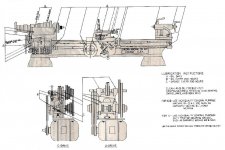

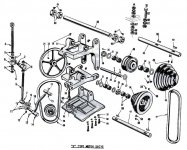

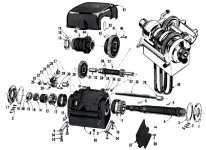

Adding some photos:

As far as material goes I would like to be able to work with cast iron, steel, and brass. Brass is easy so I imagine that won't be an issue. I do have some carbid cutters. I just wonder with the 3/4 HP motor how well the machine will do for these harder materials. I guess I won't be taking deep cuts.

Even though it is a little smaller than I wanted it is a nice lathe. The previous owner must have rebuilt it because the bed ways looked like they were recently put through a shaper and flaked.

Updates:

It's a 10.125" swing (Series XL) with 1" collet capacity.

Adding some photos: