shapeaholic

Stainless

- Joined

- Oct 14, 2003

- Location

- Kemptville Ontario, Canada

Hello folks,

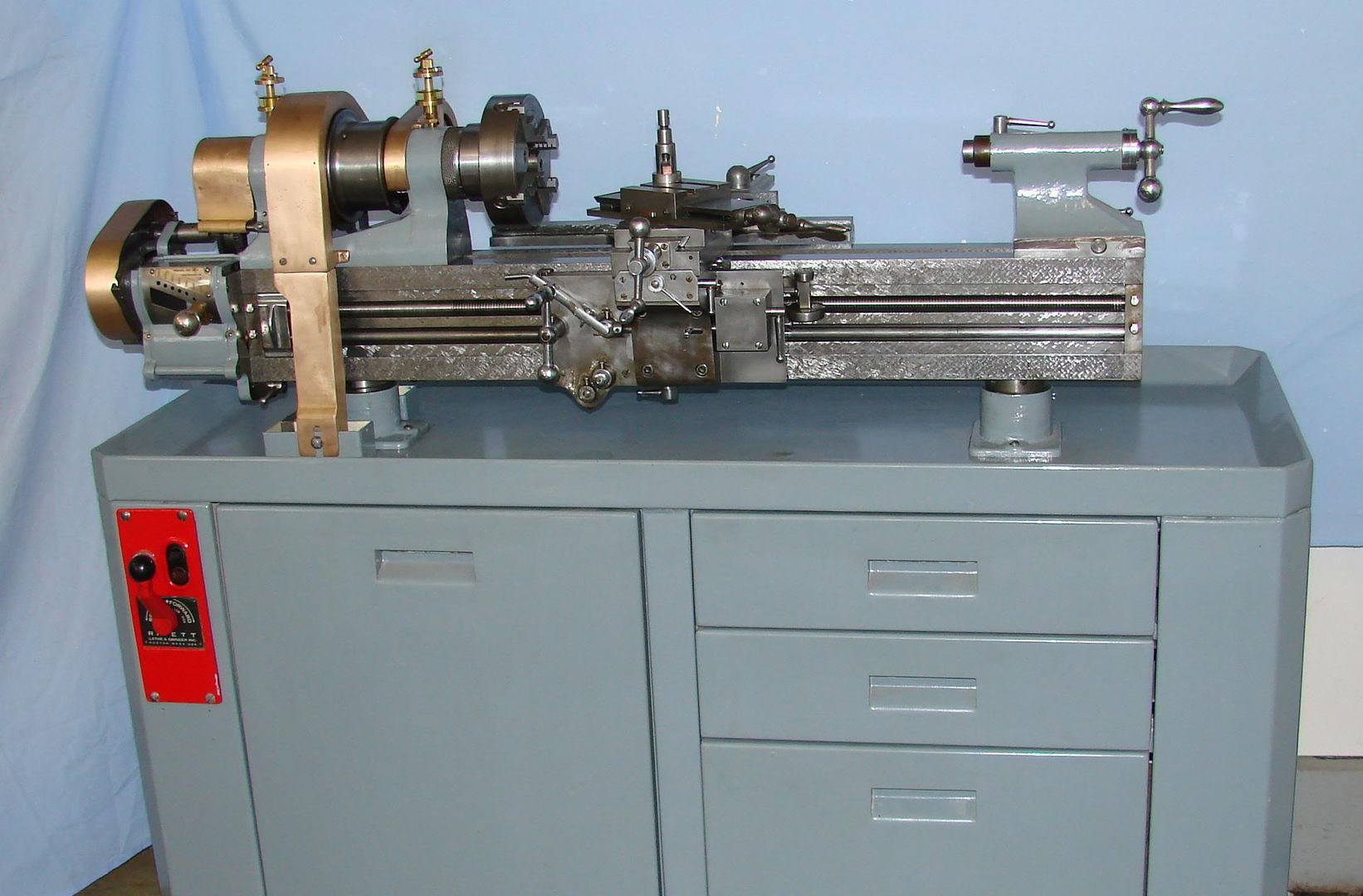

In a weeks time I am heading off on a roadtrip to pick up a S&B 1024.

I am looking for some advise as to how I should (could) lift it.

Current plan is to remove it from its current location with a backhoe loader equipped with forks, lifting from the bottom of the base.

This will work fine until I get to placing it on the trailer, because of the wheelwells.

So I will have to lift from above for that bit.

Can this lathe be lifted by placing the forks under the bed?

Is there a way to lift using straps?

I have rigged lots of equipment in the past, and have a reasonable amount of equipment. I figure it's better to ask the stupid questions before rather than after

Thanks

Peter

In a weeks time I am heading off on a roadtrip to pick up a S&B 1024.

I am looking for some advise as to how I should (could) lift it.

Current plan is to remove it from its current location with a backhoe loader equipped with forks, lifting from the bottom of the base.

This will work fine until I get to placing it on the trailer, because of the wheelwells.

So I will have to lift from above for that bit.

Can this lathe be lifted by placing the forks under the bed?

Is there a way to lift using straps?

I have rigged lots of equipment in the past, and have a reasonable amount of equipment. I figure it's better to ask the stupid questions before rather than after

Thanks

Peter