Fun story - once upon a time I needed to grind a tool bit to cut a specific contour on the lathe, so I walked over to the tool grinder and started grinding. Pretty standard operating procedure. But on this particular day, one of the office jockeys happened to escape from his corral and be wandering by, and noticed I wasn't using the proper safety equipment. Now being the chief safety officer, he proceeded to throw a fit and demand I cease and desist all activity until I had a face shield and safety glasses and the guard down on the grinder. So about five minutes later when the production manager came wandering through, he wanted to know why I was just standing in front of the grinder with it running. I told him I needed to grind a custom tool, but I hadn't figured out how to do that yet when I couldn't see the tool or grinding wheel through all the BS safety gear that the chief safety officer insisted I wear or I would be fired. He then told me to get the job done while we went and had a "talk" with the chief safety manager. Never saw him in the shop again.

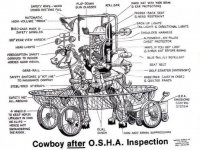

Machine tools are dangerous. Nothing you can do will ever make them not dangerous. Accidents happen, and if you are going to work around machine tools, you had better be prepared to accept that some day an accident will happen to you. We take reasonable precautions to mitigate those dangers and prevent those accidents, but there is a point where you cannot make a machine any more safe and still get work done effectively.

I worked in a shop once doing fabrication where everyone had to wear hard hats because one time some idiot knocked a hammer off a machine onto another idiots head. So in an empty building with no overhead structures or hazards at all, everyone was supposed to wear hard hats. Luckily I got moved over to another empty building doing electrical work, and I decided that in my building, I didn't need a hard hat. Since I was the only one in that building, I was technically the manager, so they couldn't argue.

I worked on another job wiring overhead lighting in a warehouse off scissor lifts. Anyone more than 4 feet off the ground had to wear a safety harness with a fall arrest lanyard attached to a certified point. Unfortunately, the only certified points in the building were on the scissor lifts themselves, and we weren't allowed to attach to them because if they fell over, then they would pull down us with them (never mind that we were standing in them anyways). So their solution was to just attach the lanyard to the harness since there was no hard points available. Basically, every electrician working 20 feet off the floor was carrying their own personal tripping hazard with them. And every one tripped on their lanyards regularly, except the one guy that went out and bought a fancy retractable one. We even tried using wire ties to bundle up the lanyards so they were not hanging right at shin height, but no that would interfere with their operation so we couldn't even do that. Because, you know, just not wearing the useless, dangerous, accident prone harnesses would be against the rules.

Use appropriate PPE where appropriate, if it's interfering with your ability to do your job, it's not appropriate.