Pstodds

Plastic

- Joined

- Apr 10, 2014

- Location

- Ipswich, United Kingdom

Hello All! Since this is my first post, Forgive me if i put this in the wrong section, just move it if it is. I am a Blacksmith, Hopefully soon too be finishing my formal training by next june, and i have a problem. One of the tutors at my college has offered me a 2 CWT In slides Massey for just £1500 which i believe is pretty damn good. The only problem with it is that the anvil is seperate from the body of the hammer, and has to be put into the ground. The Hammer then has to be lifted over the top of the anvil which i imagine to be about 2 feet without having looked at the plans yet, and the hammer is just under 3 metres high. Anyway, I priced up the cost for moving it, and it turned out to be fairly expensive to rent a forklift, although i saw it coming, i didnt realise how much these companies charge for delivery! Someone else on I forge Iron mentioned that in order to do the same operation they built a Gantry crane, which i have been looking into. I estimate the hammer to weigh in at 3-4 tons depending on how much i can strip off the thing, which i will have to do anyway in order to clean it up and inspect the cylinder. Me, and the person i am going into have level 2 Mig and arc i think, although it may be higher (i don't pay too much attention to the paperwork, just turn up and get welding lol). We are both quite confident in our welding capabilities. What i wanted to know is, since you guys are the experts, would you recommend building a gantry crane? are there any plans out there for one? What would you estimate the cost to be? Is this even safe or should i stick to getting a forklift?

Thanks for your time,

Paul Stoddart

P.S I won't be moving until next June, but i wanted to get it sorted now, and i am looking for a premises in Norfolk/Suffolk, If anyone has any advice for workshops in that area send me a PM please!

Thanks for your time,

Paul Stoddart

P.S I won't be moving until next June, but i wanted to get it sorted now, and i am looking for a premises in Norfolk/Suffolk, If anyone has any advice for workshops in that area send me a PM please!

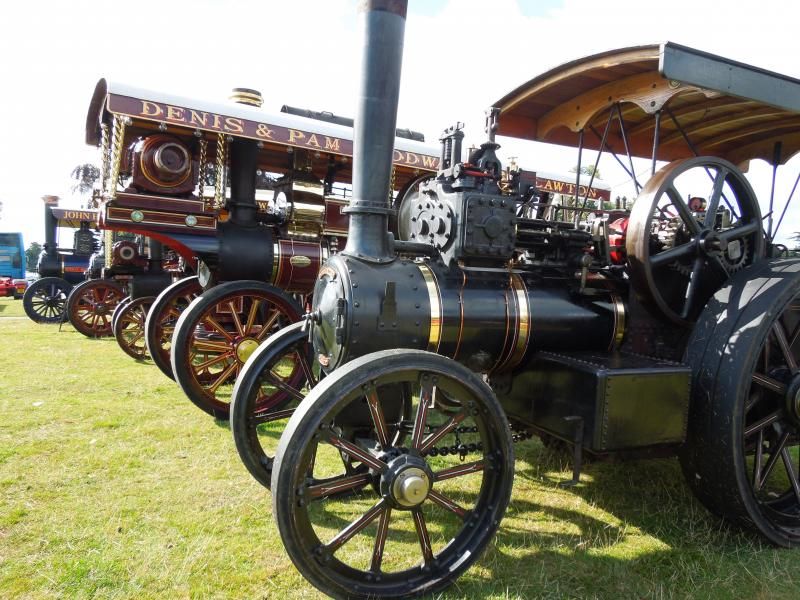

It should be far more fun for those guys than sitting around at the traction rally and not even being allowed to drive anywhere. Not sure how realistic that one would be but I bet you would have one of the best machinery moving experiences ever!

It should be far more fun for those guys than sitting around at the traction rally and not even being allowed to drive anywhere. Not sure how realistic that one would be but I bet you would have one of the best machinery moving experiences ever!