Thanks for the replies, and I will attempt to illustrate my shop and skills verbally.

I am a manual only shop. This fact makes me only competeitive in short-run, fairly simple parts and assemblies. I think that my niche will be in urgent repair work, quick turn-around, and fixtures/tools. I also think I may be useful in the product development phase of many engineering projects that can utilize my skills. I have Taiwanese machines: 10 x 42 Kent step-pulley mill, and Takang 14 x 40 engine lathe. Also support equipment including Black Diamond 2B drill grinder, and pedestal grinders. A web site is not in the budget right now, but if I get this venture rolling along and upgrade my equipment, I may get one. I aslo feel that a pictorial of my current equipment may make me look like an amateur or worse: HOBBY MACHINIST!

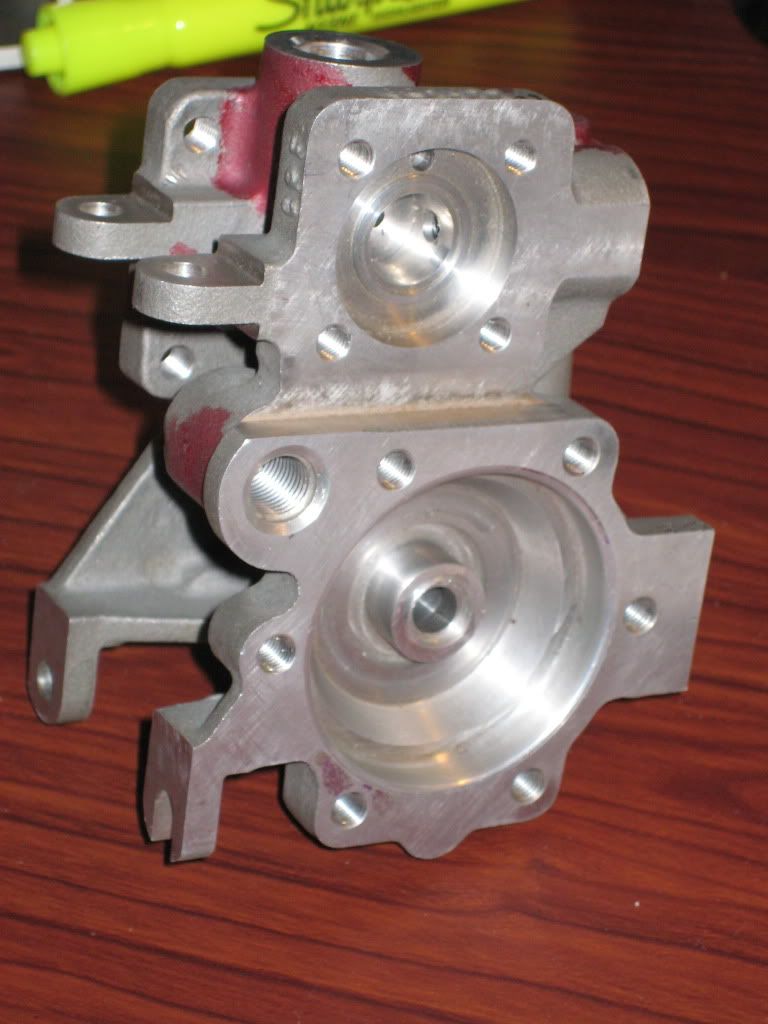

I have 23 years experience in making precision parts and assemblies for the Aerospace, Electronic, Automotive, and Commercial industries. I have only one example of some of my most involved work, done back in 1998 :

This casting, like many others I ran at this employer's place of business, had many fifth-axis holes with .010" True Position callouts, and many of the bores were .001" total tolerance after hard anodization. Granted the equipment was first rate there, but the machines don't make the parts, the monkey, er, um, I mean the Machinist does.

Is there hope to gather income to supplement and hopefully surpass my current 40 hr./week pay?