Locoguy,

Information on defunct British machine tool makers is hard to find. I found this by Googling:-

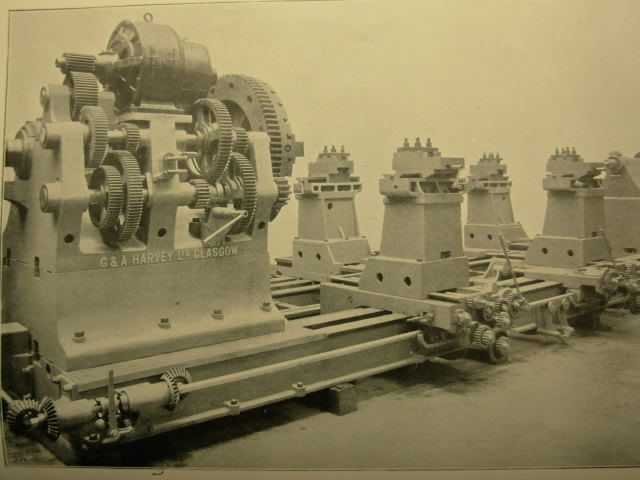

‘G & A Harvey, engineers and machine tool makers, were founded in 1857 in Govan, Glasgow, Scotland. The company’s works were located at the Albion Works, Govan, and produced a wide range of heavy lathes, slotting, planing, boring and screwing machines.

In 1937, the company came together with 4 other engineering and machine tool makers to form Scottish Machine Tool Corporation Ltd. These companies, namely James Bennie & Sons Ltd, Glasgow; Loudon Bros Ltd, Johnstone, Renfrewshire, Scotland; Craig & Donald Ltd, Johnstone; and James Allan Senior & Sons Ltd, Glasgow; all retained their separate autonomy, even though they had amalgamated. Joint catalogues were produced under the name Scottish Machines Tools Corporation Ltd yet machines were branded with the name of their own manufacturer. In the late 1960s, Scottish Machine Tool Corporation Ltd became an associate of Wilkins-Mitchell, forging equipment manufacturers, and in 1982 it went into liquidation.

Source:

Michael Moss & John Hume, Workshop of the British Empire: Engineering and Shipbuilding in the West of Scotland (London, 1977).’

From:-

http://www.archives.gla.ac.uk/collects/catalog/ugd/151-200/ugd175-4.html

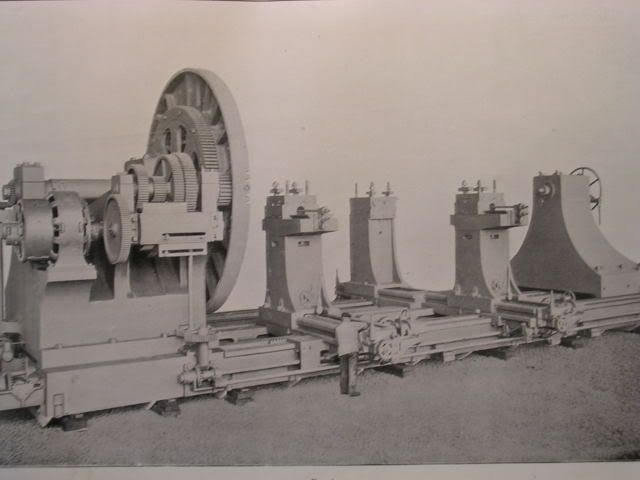

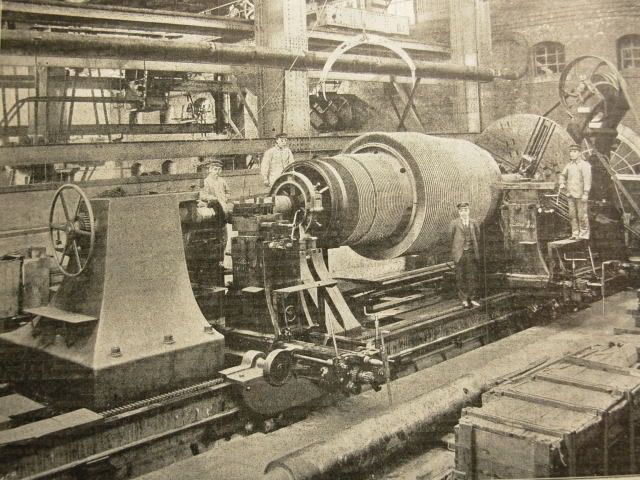

There’s a bit of info in ‘A History of Machine Tools 1700-1910’ by W Steeds., including a picture of an unusual boring machine from 1863. This looked like a plano-miller, but the horizontal bridge could be tilted. Also, the table had an inserted portion that could be tilted. Another picture shows a duplex wheel lathe from 1892. This has two headstocks, side by side and back to back, slightly staggered – a space-saving arrangement.