How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do I replace the guide pin for R8 collets?

- Thread starter 67Charger

- Start date

- Replies 19

- Views 9,703

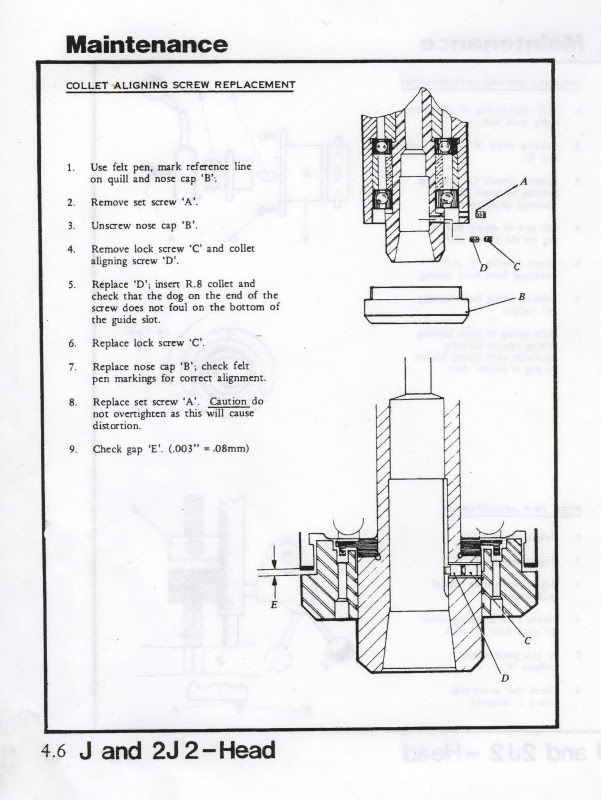

you need to take the quill nose off to get to the pair of screws. IMO you're better off just leaving them out all together.

pics of the procedure can be found here: http://home.comcast.net/~tom.jelly/j head rebuild web page/j head rebuild.htm

pics of the procedure can be found here: http://home.comcast.net/~tom.jelly/j head rebuild web page/j head rebuild.htm

piniongear

Stainless

- Joined

- Jun 26, 2006

- Location

- Canyon Lake Texas

And here is a simple answer........Simple question... The J-head I just picked up has a mashed pin in the quill so it is difficult locating the collets on it. How do I replace it?

I am a member of the camp who wants to have the (dog nose) collet aligning pin in there at all times.

It prevents the collet from turning when you tighten things up.

Some people feel just the opposite. To each their own, but Bridgeport had a reason to put it there......... pg

Edit Note:

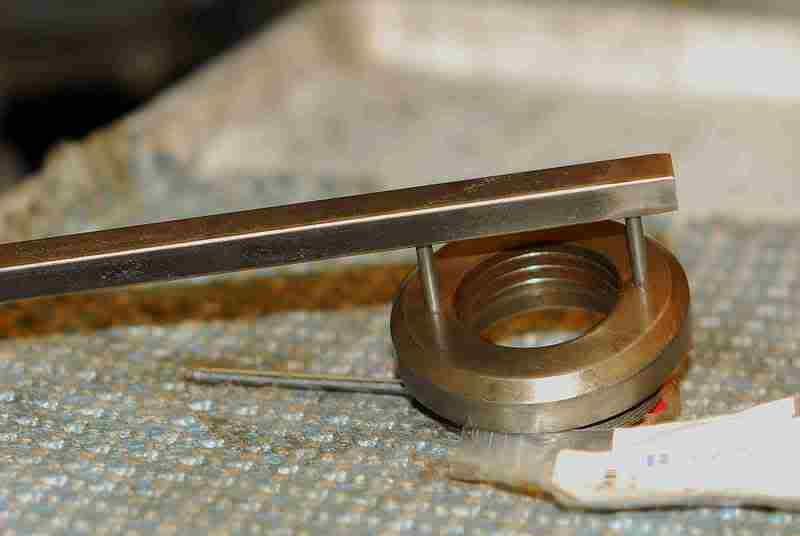

You will need to make a tool to remove the nose piece.

Here is a pic of the one I made to remove mine.

Simple flat bar with 2 pins inserted in holes drilled on correct center to center of holes in nose cap.

Last edited:

Newman109

Diamond

- Joined

- Sep 4, 2006

It's a right-hand thread on the nose piece on a real Bridgeport and left Hand thread on my Webb and other Asian imports, I presume.

piniongear

Stainless

- Joined

- Jun 26, 2006

- Location

- Canyon Lake Texas

Yes on the BPT. Right hand thread it is...... pgIt's a right-hand thread on the nose piece on a real Bridgeport and left Hand thread on my Webb and other Asian imports, I presume.

rons

Diamond

- Joined

- Mar 5, 2009

- Location

- California, USA

From the pictures you see a locating screw and a locking screw. They are 1/4-32. None of my local supply businesses carry them. I had to make a new

locking screw from a socket cap screw. Turned out just right.

If you want to make a pin wrench that removes the cap piece as well as the two collars

on the top of the head you can get two flat bars of stock (1/8x1/2x14) and on each end

tap a 1/4-20 thread. Into those holes you can machine down 1/4-20 bolts to whatever

diameter you need. At the other end of the bars bolt them in whatever way you can

so the hole thing has a scissors action. Very useful pin wrench. I can remove the two

collars on the head, the quill cap, and the bearing retaining cap on my lathes collet closure.

locking screw from a socket cap screw. Turned out just right.

If you want to make a pin wrench that removes the cap piece as well as the two collars

on the top of the head you can get two flat bars of stock (1/8x1/2x14) and on each end

tap a 1/4-20 thread. Into those holes you can machine down 1/4-20 bolts to whatever

diameter you need. At the other end of the bars bolt them in whatever way you can

so the hole thing has a scissors action. Very useful pin wrench. I can remove the two

collars on the head, the quill cap, and the bearing retaining cap on my lathes collet closure.

walter west

Cast Iron

- Joined

- Jan 21, 2002

- Location

- grand haven,mi., USA

Collet guide

Throw the damned thing away. My BP has run fine for 7 years without it

Walt

Throw the damned thing away. My BP has run fine for 7 years without it

Walt

piniongear

Stainless

- Joined

- Jun 26, 2006

- Location

- Canyon Lake Texas

Heh-Heh!

Like I had said, there are definitely two camps on this one.

One camp is right and one camp is wrong.

I leave it to you to figure that one out for yourself....... pg

Like I had said, there are definitely two camps on this one.

One camp is right and one camp is wrong.

I leave it to you to figure that one out for yourself....... pg

It prevents the collet from turning when you tighten things up.

not needed for that either. when i install a collet by hand i force it all the way up into the taper and then spin the drawbar until it's finger tight. after that i can let go and hold the brake with one hand and the wrench with the other. if i'm using an impact wrench then i just hold it up into the taper and spin the drawbar down until tight, no need to finger tighten first or to use the brake. in either case the collet does not rotate in the taper from it's initial position i hold it in. try it.

every once in a while i use a friends BP that does have the pin in and it's a major pain in the ass. despite his kurt power drawbar tool changes are slower than on my machine with a hand held makita impact wrench.

dave

piniongear

Stainless

- Joined

- Jun 26, 2006

- Location

- Canyon Lake Texas

And another advantage of using the pin is it locates the collet in the same place every time the collet goes in the spindle.

No chance of installing the collet 180° from where you last used it.

I always look at it this way.........

The people at Bridgeport knew far more than I ever will about the machine.

I really do not believe they would include a costly feature on the machine for years and years of manufacture unless they felt it was something needed. So I agree with them fully and use the pin. It has never caused me any problem unless it gets banged up. Then I replace it and have no problem.

You have problems with your friend's pin equipped mill because he has a banged up pin. He needs to work on that machine a bit.

But this issue is the same as the old Ford/Chevy argument that has gone on for years now and will never be decided............... pg

pg

No chance of installing the collet 180° from where you last used it.

I always look at it this way.........

The people at Bridgeport knew far more than I ever will about the machine.

I really do not believe they would include a costly feature on the machine for years and years of manufacture unless they felt it was something needed. So I agree with them fully and use the pin. It has never caused me any problem unless it gets banged up. Then I replace it and have no problem.

You have problems with your friend's pin equipped mill because he has a banged up pin. He needs to work on that machine a bit.

But this issue is the same as the old Ford/Chevy argument that has gone on for years now and will never be decided...............

pg

pgThe real Leigh

Diamond

- Joined

- Nov 23, 2005

- Location

- Maryland

Lock da spindle

Put the top shift lever in high gear (pointing forward) and the side lever in back gear (also pointing forward).

Locks the spindle up tighter than an old maid's purse.

Tighten/loosen all you want, you're not going to move the spindle one degree.

Of course, remember to shift the handles to the desired speed range before you start the mill, 'cause it won't start with the handles as described.

Also works for tightening/loosening keyless chucks and anything else that wants the spindle to stay put.

- Leigh

MUCH easier way to tighten the collet......hold the brake with one hand and the wrench with the other.

Put the top shift lever in high gear (pointing forward) and the side lever in back gear (also pointing forward).

Locks the spindle up tighter than an old maid's purse.

Tighten/loosen all you want, you're not going to move the spindle one degree.

Of course, remember to shift the handles to the desired speed range before you start the mill, 'cause it won't start with the handles as described.

Also works for tightening/loosening keyless chucks and anything else that wants the spindle to stay put.

- Leigh

Newman109

Diamond

- Joined

- Sep 4, 2006

I had to replace the pin in my Webb R8 spindle when I refurbished the machine. The Webb uses a 6mm set screw with a dogbone point and a short 6mm to lock it in place.

I prefer having the pin in place to locate the R8 tools the same way every time. I use the spindle brake to hold the spindle while I tighten the drawbar. It works for me.

There are two warring camps on this issue and Pinion Gear and I are correct, of course. LOL

I prefer having the pin in place to locate the R8 tools the same way every time. I use the spindle brake to hold the spindle while I tighten the drawbar. It works for me.

There are two warring camps on this issue and Pinion Gear and I are correct, of course. LOL

MUCH easier way to tighten the collet...

Put the top shift lever in high gear (pointing forward) and the side lever in back gear (also pointing forward).

Locks the spindle up tighter than an old maid's purse.

Tighten/loosen all you want, you're not going to move the spindle one degree.

Of course, remember to shift the handles to the desired speed range before you start the mill, 'cause it won't start with the handles as described.

Also works for tightening/loosening keyless chucks and anything else that wants the spindle to stay put.

- Leigh

only problem i have with that is the stress i can imagine is put on my very old timing belt, finding a replacement over here isn't so easy. but i also like that by using the brake i can "ratchet" the wrench by releasing the brake and rotating back to the starting point instead of taking the wrench off the drawbar over and over. moot point anyways as i much prefer the impact wrench that doesn't require locking up the spindle at all.

and to those who think it's important that the pin keeps the collet in the same orientation every time it's used i say so what? if your spindle taper is in good shape you should get the same runout no matter how you put the collet in. and for it to really matter you would need to make sure the end mill you're using goes into the collet the same way every time as well.

You have problems with your friend's pin equipped mill because he has a banged up pin. He needs to work on that machine a bit.

nope, pristine pin and real bridgeport collets. i'm just used to stuffing the collet in and going, on his machine it seems i alway go in 180° off and have to fumble around to find the slot.....kinda like sex in the dark...

Doozer

Titanium

- Joined

- Jul 23, 2001

- Location

- Buffalo NY

..."I always look at it this way.........

The people at Bridgeport knew far more than I ever will about the machine."...

What they "knew" is that there are some people out there in humanity that could not figure out what to do when they try and thread in a collet, and the collet spins. Some poor rube spinning the drawbar, and sees the collet spinning and thinks there must be something wrong. He thinks it is owed to him by some God given premise that his collet should not spin. How dare he have to touch the collet while tightening it. Grabbing a collet with his left hand might mean he is gay or something. Wouldn't want that. So to avoid all this drama, Bridgeport included the key. That's how I see it, others may and probably will differ.

--Doozer

The people at Bridgeport knew far more than I ever will about the machine."...

What they "knew" is that there are some people out there in humanity that could not figure out what to do when they try and thread in a collet, and the collet spins. Some poor rube spinning the drawbar, and sees the collet spinning and thinks there must be something wrong. He thinks it is owed to him by some God given premise that his collet should not spin. How dare he have to touch the collet while tightening it. Grabbing a collet with his left hand might mean he is gay or something. Wouldn't want that. So to avoid all this drama, Bridgeport included the key. That's how I see it, others may and probably will differ.

--Doozer

piniongear

Stainless

- Joined

- Jun 26, 2006

- Location

- Canyon Lake Texas

H-mmm, interesting observation you have there...."I always look at it this way.........

The people at Bridgeport knew far more than I ever will about the machine."...

What they "knew" is that there are some people out there in humanity that could not figure out what to do when they try and thread in a collet, and the collet spins. Some poor rube spinning the drawbar, and sees the collet spinning and thinks there must be something wrong. He thinks it is owed to him by some God given premise that his collet should not spin. How dare he have to touch the collet while tightening it. Grabbing a collet with his left hand might mean he is gay or something. Wouldn't want that. So to avoid all this drama, Bridgeport included the key. That's how I see it, others may and probably will differ.

--Doozer

My mill has a Kurt automatic drawbar on it now, but before it did.......

I used one hand to tighten the drawbar with the wrench and the other hand to hold on to the spindle brake.

Now, you must have 3 hands so you can touch the collet at the same time? Or if you have some other trick, please share it with us........ pg

Doozer

Titanium

- Joined

- Jul 23, 2001

- Location

- Buffalo NY

Once you hand tighten the collet, using one hand to hold the collet and one hand to turn the drawbar, the collet will stay once it is hand snug. Then use the brake and wrench to finish tighten. If you really have to grip the collet, the threads may be a little dirty, run a 7/16-20 tap in your collets and they should thread freely. Try it, you'll like it

--Doozer

--Doozer

Peter Neill

Stainless

- Joined

- Apr 30, 2006

- Location

- Suffolk, England

H-mmm, interesting observation you have there.

My mill has a Kurt automatic drawbar on it now, but before it did.......

I used one hand to tighten the drawbar with the wrench and the other hand to hold on to the spindle brake.

Now, you must have 3 hands so you can touch the collet at the same time? Or if you have some other trick, please share it with us........ pg

The Bridgeport spindle brake lever is cammed - just lift it upwards after you have shoved it sideways to lock the brake.

Simples. No need for 3 hands.

rons

Diamond

- Joined

- Mar 5, 2009

- Location

- California, USA

I operated my mill for several years before I found out that there was supposed

to be a guide pin. The original owner had backed it out for some reason. The

lock screw was a joke. I made everything right again. I notice little difference

when installing a collet, except that I have to rotate the collet until it slides up.

No big deal in my opinion.

to be a guide pin. The original owner had backed it out for some reason. The

lock screw was a joke. I made everything right again. I notice little difference

when installing a collet, except that I have to rotate the collet until it slides up.

No big deal in my opinion.

..."I always look at it this way.........

The people at Bridgeport knew far more than I ever will about the machine."...

What they "knew" is that there are some people out there in humanity that could not figure out what to do when they try and thread in a collet, and the collet spins. Some poor rube spinning the drawbar, and sees the collet spinning and thinks there must be something wrong. He thinks it is owed to him by some God given premise that his collet should not spin. How dare he have to touch the collet while tightening it. Grabbing a collet with his left hand might mean he is gay or something. Wouldn't want that. So to avoid all this drama, Bridgeport included the key. That's how I see it, others may and probably will differ.

--Doozer

yep, pandering to the lowest common denominator is by no means something new. engineer A probably brought the newly designed collet to engineer B and said "now how do we make this thing idiot proof?"

dave

Similar threads

- Replies

- 14

- Views

- 823

- Replies

- 1

- Views

- 156

- Replies

- 6

- Views

- 271

- Replies

- 21

- Views

- 2K

- Replies

- 6

- Views

- 247