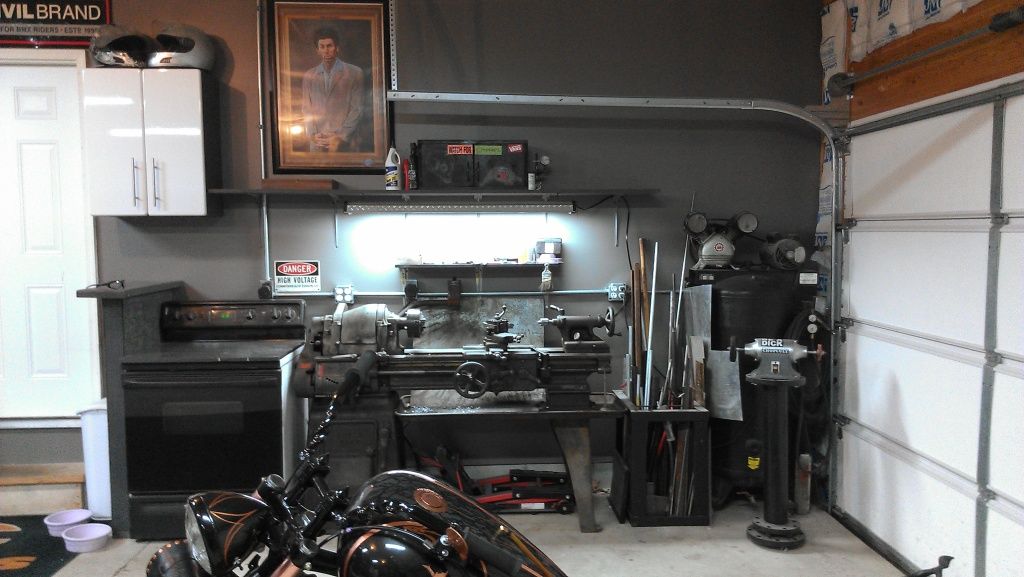

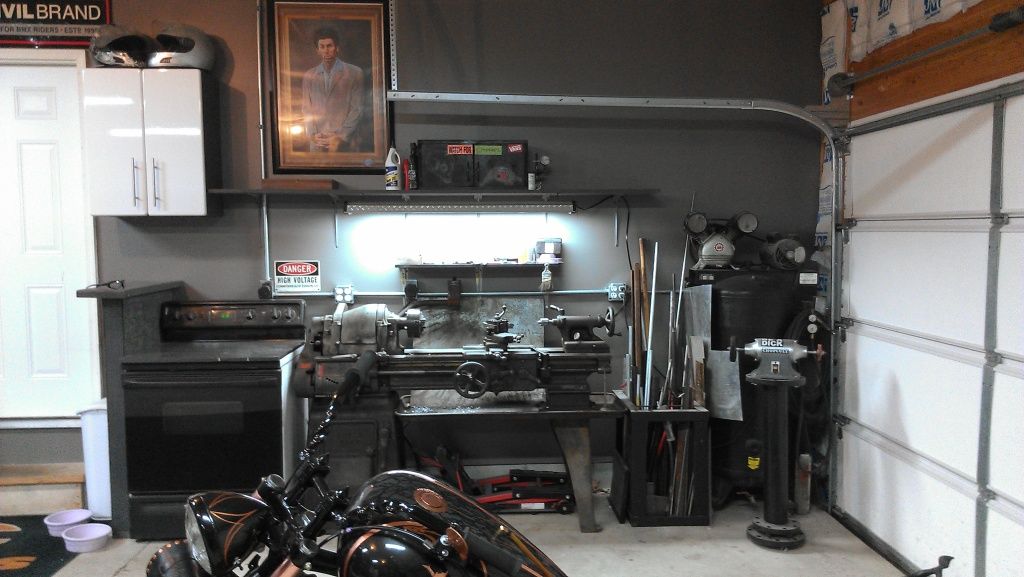

hi guys, picked up this lathe last december. was my first. learned quite a bit on it, making mostly motorcycle parts.(forward controls, spacers, bungs, etc.. we moved a few months ago, had the lathe broken down to pieces, re assembled it in the new garage, and now the chuck is spinning .030 off center. The main shaft is spinning true, pullys are spinning true, just the chuck is off. i tried loosening the 3 bolts holding the chuck on and moving it around using and indicator and still .030 is the BEST i can get. Any thoughts here?? i need to start using it again soon for a bike build. Might just be ordering a new jaw and backplate...