cvmikeray

Aluminum

- Joined

- Nov 25, 2008

- Location

- Birmingham, Alabama USA

Well my search for a lathe (this time  ) has ended with the purchase of a 1981 South Bend 13 inch machine with a taper attachment. It is a really clean machine and looks like it has been taken care of. Once I get it on the floor of my shop I will get some close ups of the various areas. It has one issue where the piece of the taper attacehment that hooks to the cross slide has been broken and repaired. But the repair looks to have been very well done.

) has ended with the purchase of a 1981 South Bend 13 inch machine with a taper attachment. It is a really clean machine and looks like it has been taken care of. Once I get it on the floor of my shop I will get some close ups of the various areas. It has one issue where the piece of the taper attacehment that hooks to the cross slide has been broken and repaired. But the repair looks to have been very well done.

Specs:

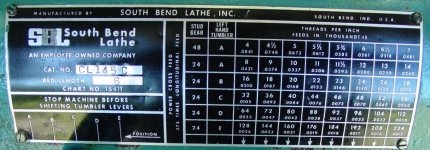

SOUTH BEND 13" X 42" CC ENGINE LATHE WITH TAPER ATTACHMENT

SERIAL NUMBER: 16725T

Catalog Number: CL145C

Approximate Year: 1981

Specifications:

Swing: 13"

Bed Length: 6'

Spindle Speeds IN RPM, 4 Step Pulley

Open Belt: 270, 418, 628 And 940 RPM

Back Gear: 40, 60, 90 And 135 RPM

Tailstock Spindle Nose: No. 3 Morse Taper

Spindle Nose: D1-4 Cam Lock

Thru Hole: 1 3/8"

48 Feed Ranges: .0015-.0841

48 Thread Ranges: 4-224 TPI, ON Quick Change

Gear Box

Equipped With:

Taper Attachment With Bed Clamp

Flame Hardened Bedways

Cushman 6" Diameter 3 Jaw Scroll Chuck

Chuck Guard

Graduated Hand Dials

Micro Adjustable Stop

Four Position Tool Holder With Z Cutters

Live Center

Dead Center

Wrenches

Under Carriage Motor Design

Start/Stop, Forward/Reverse Push Buttons

2 HP, 220/440 Volt, 1730 RPM, 3 Phase Motor,

(Currently Wired For 440 Volts)

) has ended with the purchase of a 1981 South Bend 13 inch machine with a taper attachment. It is a really clean machine and looks like it has been taken care of. Once I get it on the floor of my shop I will get some close ups of the various areas. It has one issue where the piece of the taper attacehment that hooks to the cross slide has been broken and repaired. But the repair looks to have been very well done.

) has ended with the purchase of a 1981 South Bend 13 inch machine with a taper attachment. It is a really clean machine and looks like it has been taken care of. Once I get it on the floor of my shop I will get some close ups of the various areas. It has one issue where the piece of the taper attacehment that hooks to the cross slide has been broken and repaired. But the repair looks to have been very well done. Specs:

SOUTH BEND 13" X 42" CC ENGINE LATHE WITH TAPER ATTACHMENT

SERIAL NUMBER: 16725T

Catalog Number: CL145C

Approximate Year: 1981

Specifications:

Swing: 13"

Bed Length: 6'

Spindle Speeds IN RPM, 4 Step Pulley

Open Belt: 270, 418, 628 And 940 RPM

Back Gear: 40, 60, 90 And 135 RPM

Tailstock Spindle Nose: No. 3 Morse Taper

Spindle Nose: D1-4 Cam Lock

Thru Hole: 1 3/8"

48 Feed Ranges: .0015-.0841

48 Thread Ranges: 4-224 TPI, ON Quick Change

Gear Box

Equipped With:

Taper Attachment With Bed Clamp

Flame Hardened Bedways

Cushman 6" Diameter 3 Jaw Scroll Chuck

Chuck Guard

Graduated Hand Dials

Micro Adjustable Stop

Four Position Tool Holder With Z Cutters

Live Center

Dead Center

Wrenches

Under Carriage Motor Design

Start/Stop, Forward/Reverse Push Buttons

2 HP, 220/440 Volt, 1730 RPM, 3 Phase Motor,

(Currently Wired For 440 Volts)

) but I talked to Mr. Sorensen about the machine and what he said was true that it is a nice machine with low usage.

) but I talked to Mr. Sorensen about the machine and what he said was true that it is a nice machine with low usage.