I'm making slow progress on my SB 10L. It really is fun, just more fun when you get all the grease, grime, swarf, oil off the machine and see what the nice parts look like! The painting is therapy for sure. My thanks to all of the posts of restoring these classic lathes as they are inspirational.

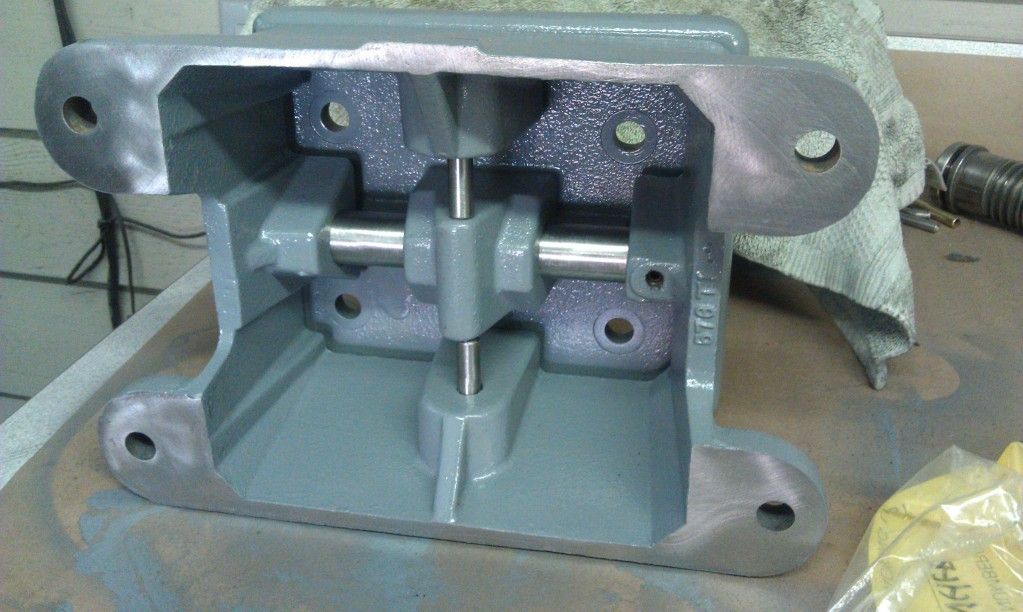

Some of the early photos....

Some of the early photos....