gnead

Plastic

- Joined

- Apr 28, 2012

- Location

- North Carolina

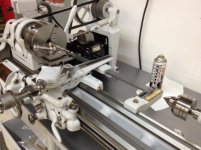

I am kinda new here, been lurking for a while not really posting, finally have something to post about so here goes, I bought this SB 9" in NY, I have had it for about 6 months and not had time to touch it,

about a month ago I started on it and got most of the machine done as well as the drive unit.

I needed to build the bench, last week I built it, painted it and started the final assembly.

I have a little more work to do but so far I am very happy with the results. I know some people will not like the color but I really do not like dark machines, so I went with a light gray. One of the things I have a question about is the machine has 1" risers on the head and tailstock as well as under the compound making it a 10" swing. Anyone seen this before?

Gene Nead

View attachment 64482

about a month ago I started on it and got most of the machine done as well as the drive unit.

I needed to build the bench, last week I built it, painted it and started the final assembly.

I have a little more work to do but so far I am very happy with the results. I know some people will not like the color but I really do not like dark machines, so I went with a light gray. One of the things I have a question about is the machine has 1" risers on the head and tailstock as well as under the compound making it a 10" swing. Anyone seen this before?

Gene Nead

View attachment 64482