jwallweyfoundry

Aluminum

- Joined

- Apr 17, 2006

- Location

- omaha ne

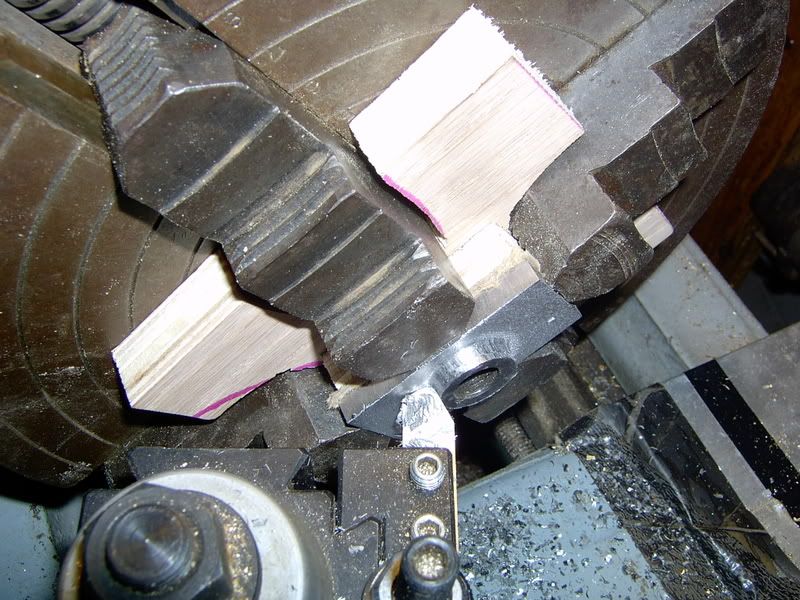

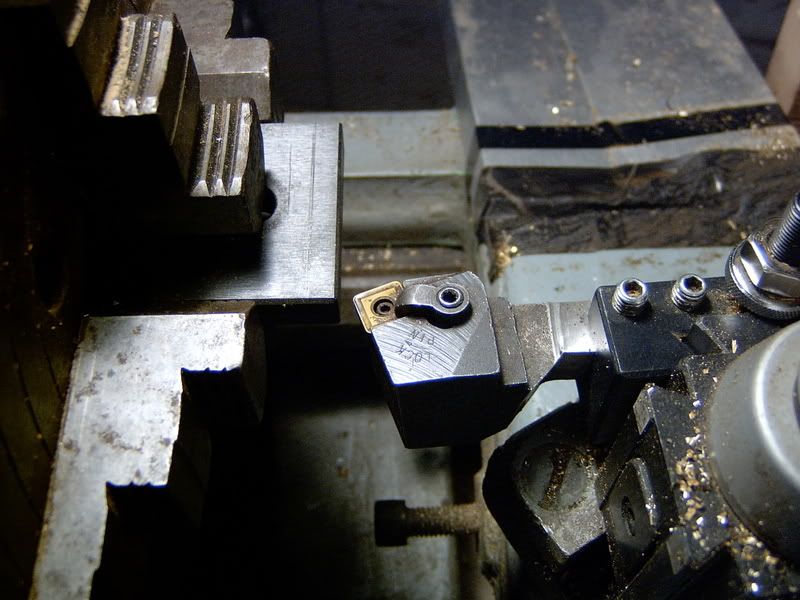

Well I stole this idea from an older HSM but thought would share for anyone who might have not seen or thought of this.

All this to mill a the T-nut for my new quick change tool post. If anyone has done something like this and has a better idea let me know this was the best i could come up with from what i have. I will try and keep everyone up to date as the milling progresses. now i need to have some hold downs for the work 7/16 if I remember correct. That is the next hurdle.

All this to mill a the T-nut for my new quick change tool post. If anyone has done something like this and has a better idea let me know this was the best i could come up with from what i have. I will try and keep everyone up to date as the milling progresses. now i need to have some hold downs for the work 7/16 if I remember correct. That is the next hurdle.