jayhawkman

Stainless

- Joined

- Mar 22, 2005

- Location

- kansas city kansas

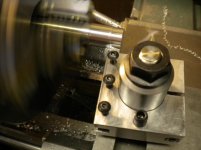

When ever I get a lathe in the shop the first thing I do is take the lantern toolpost off and throw it in my swap meet box. I am completely surprised how guys buy these things. I can sell complete ones for $30-$40 all day long. I have been putting phase II quick change toolpost on the lathes I fix up but they have jumped to about $150 although you can still find deals on ebay ever once in a while. Anyway I found a print for a really cool toolpost on the web a couple of weeks ago and made one to fit my logan by changing a couple of diamentions. This toolpost can fit any of the small lathes out there has a height adjustment and is also great if you are fixing up a lathe for resale and dont want to put out the buck and a half for a china quick change. I am not currently tring to sell these on ebay would thought I would test the water here. Asking $60 including shipping. I will machine the base to fit your lathe. If you are new to the hobby and are using a lantern toolpost this "rigid" toolpost will make your life alot easier or you are a buy and sell guy you know the value of a good toolpost. You can call me at 913 636 6107 if you have any questions. Thanks Mike