Greetings all,

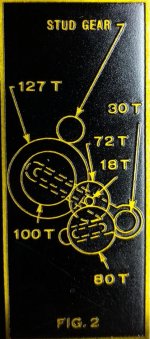

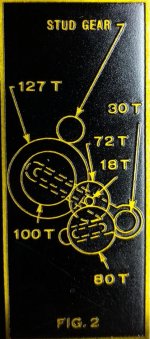

Some time ago I purchased a metric transposing gear set for my single-tumbler Heavy 10 and am finally trying to install it. Running into issues getting the gears to mesh and am not sure where I'm going wrong. I'm using the "figure 2" setup from the chart to cut a 1.5mm thread:

...and the three primary gears on the banjo won't line up. The 80T (right) can't be positioned to mesh with the 72T/18T (middle), you can see the gap in the following shot:

The configuration shown is the closest I've come but the middle and right gears aren't sitting flush with the banjo. I can address that with some spacers but I don't know if it's a further indicator of something set up incorrectly. There just doesn't seem to be enough travel in the necessary directions to make this work.

I'm hoping someone has done this successfully, but I haven't been able to find any posts or images of this setup with the full kit.

Thanks in advance for any help!

Some time ago I purchased a metric transposing gear set for my single-tumbler Heavy 10 and am finally trying to install it. Running into issues getting the gears to mesh and am not sure where I'm going wrong. I'm using the "figure 2" setup from the chart to cut a 1.5mm thread:

...and the three primary gears on the banjo won't line up. The 80T (right) can't be positioned to mesh with the 72T/18T (middle), you can see the gap in the following shot:

The configuration shown is the closest I've come but the middle and right gears aren't sitting flush with the banjo. I can address that with some spacers but I don't know if it's a further indicator of something set up incorrectly. There just doesn't seem to be enough travel in the necessary directions to make this work.

I'm hoping someone has done this successfully, but I haven't been able to find any posts or images of this setup with the full kit.

Thanks in advance for any help!