xplodee

Hot Rolled

- Joined

- Oct 14, 2013

- Location

- Allentown, PA

I'd like to introduce myself: I was directed here from a friend, Dan Wyatt. You may recall his beautifully restored giant South Bend lathe.

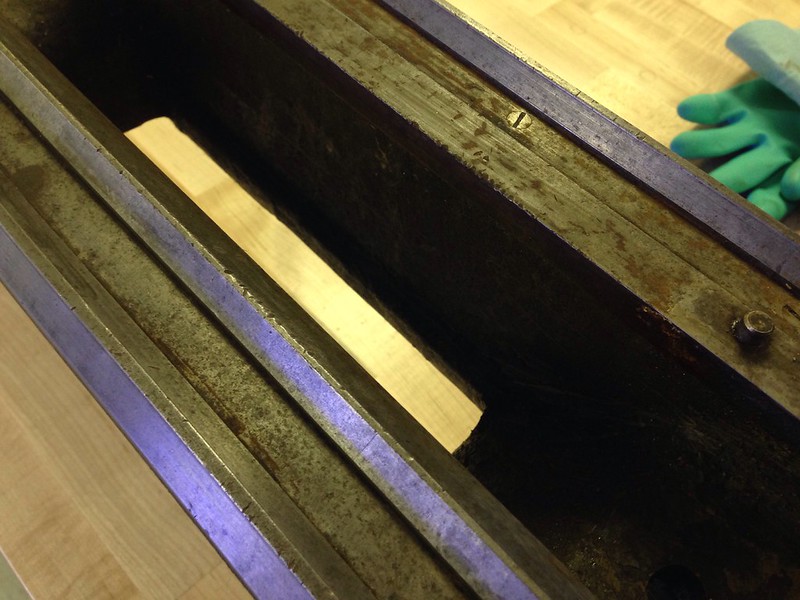

I found a Heavy 10 on craigslist and picked it up yesterday. It is missing a motor, but I'm ok with that because I plan to add a three phase motor with a VFD. I paid $750 and came home with the following parts, the machine is an earlier single tumbler Heavy 10 with 48" bed and stand and was originally a war effort machine from the USAF, I'm assuming its an early '40's model.

Images below:

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

I found a Heavy 10 on craigslist and picked it up yesterday. It is missing a motor, but I'm ok with that because I plan to add a three phase motor with a VFD. I paid $750 and came home with the following parts, the machine is an earlier single tumbler Heavy 10 with 48" bed and stand and was originally a war effort machine from the USAF, I'm assuming its an early '40's model.

Images below:

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr

Untitled by Tim Marks, on Flickr