mbogo375

Aluminum

- Joined

- Jul 6, 2008

- Location

- SE Georgia

I hope everyone will bear with a newbie for his first post. I have gotten some great information on this site, even though this is my first post. Thanks to all of you.

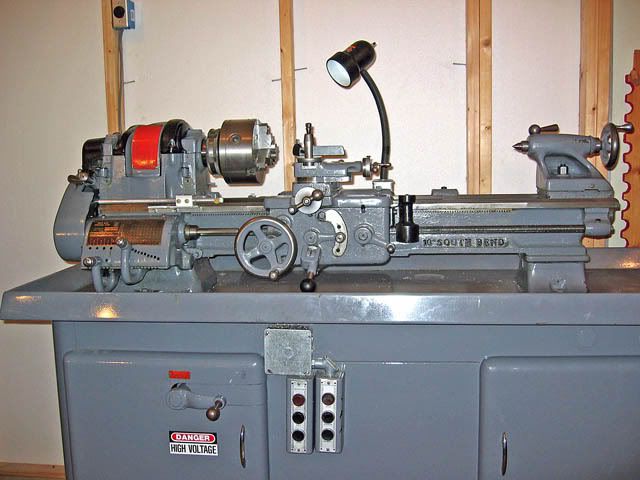

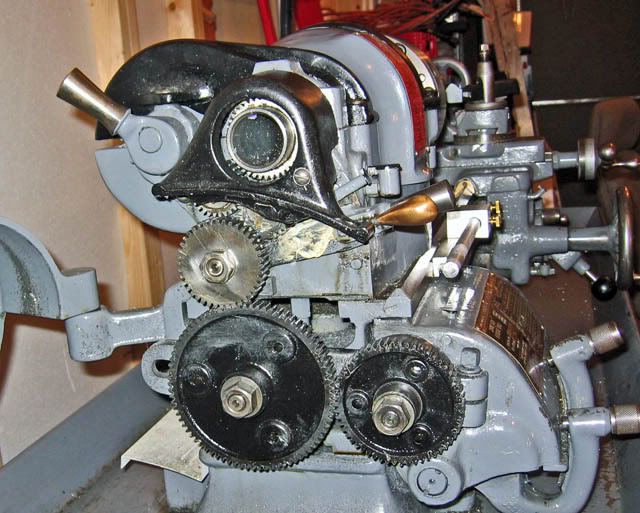

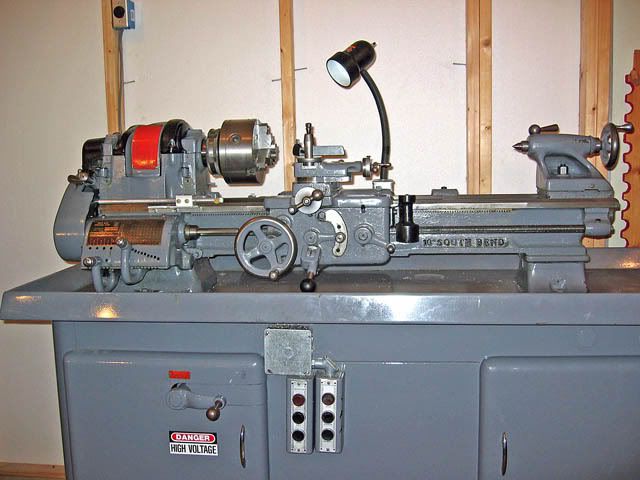

Well, I finally took the plunge and bought a lathe (my first other than a mini-lathe). I just finished getting it into my shop, and it needs a good cleanup, as well as more familiarization on my part, but that will come with time .

.

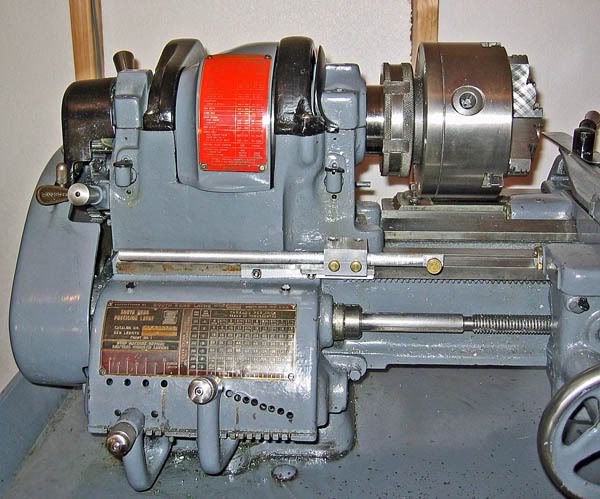

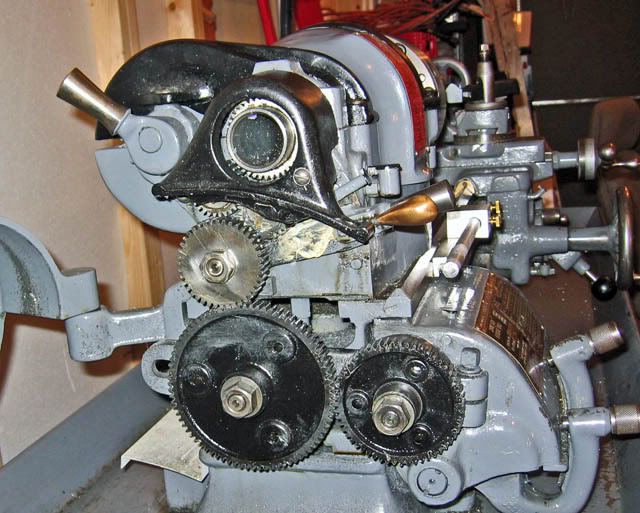

I bought this lathe on very short notice, and I HOPE that I didn't go too far into the deep end without a lifeguard. I actually didn't even know the model number and serial number until I unloaded it today , only that it was a 10L. The model number turned out to be CLK 8187 AB, and the serial number is 15990RKK 16. Am I to assume this was a "toolroom" lathe from the first 8 in the model number? Also, I assume that it was made around 1966?

, only that it was a 10L. The model number turned out to be CLK 8187 AB, and the serial number is 15990RKK 16. Am I to assume this was a "toolroom" lathe from the first 8 in the model number? Also, I assume that it was made around 1966?

The ways aren't bad, but there is an area where the tailstock caused a slight bit of extra wear in the central area of the way, and it shows as a line with the original finish below, but worn smooth above. There are a few small dings, but nothing that is too noticeable (seems not to be raised much if any, compared to the surrounding surface, but I will find out more tomorrow).

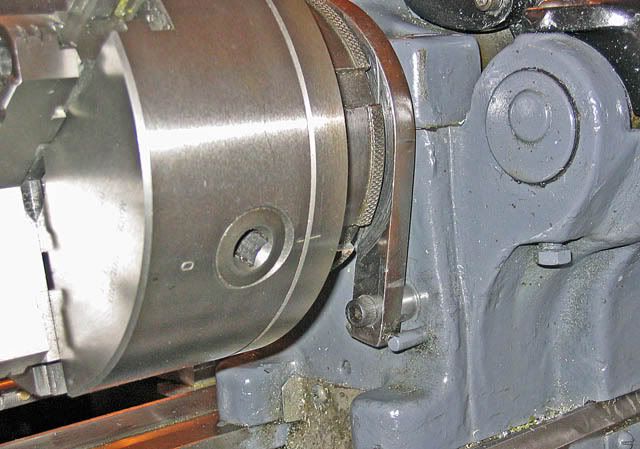

I got a pleasant surprise when I discovered that it had a taper attachment that the seller had not mentioned (the original photos did not show that area, and were pretty blurry in any case). The seller also did not mention the type spindle, but I assumed that it was a L taper from the photos, and it proved to be. I think it is an L00 from the 3 3/4" thread diameter, is this correct?

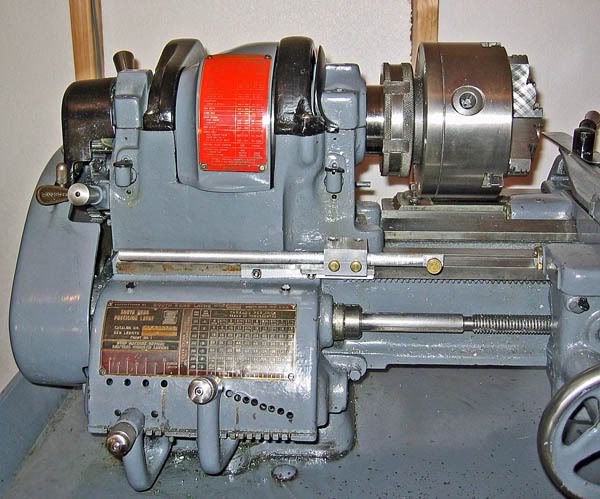

It also had an almost new Bison 3-jaw chuck, as well as the original 3-jaw. I am now in the market for a 4-jaw.

Another nice extra was a telescoping steady rest (but no follow rest).

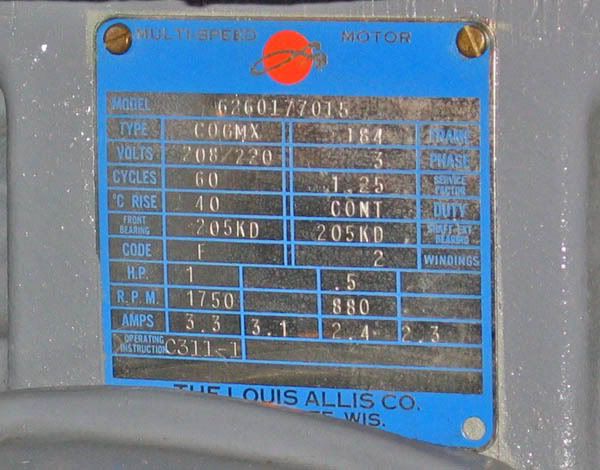

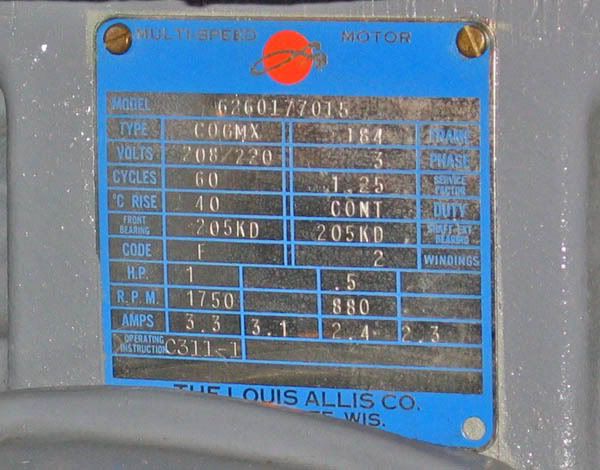

I also got another surprise that I had not expected when looking at the motor. The seller had stated that it was a single phase, two speed motor, but the plate says 3 phase. Not being knowledgeable on things electrical, is it possible that it could have been re-wired for single phase? If not, I guess I will be in the market for a phase converter. If it helps in determining whether it is three phase, the plug is a four prong rather than a three prong (see, I told you I was electrically challenged).

It also appears that some tooling got lost in shipment, like wrenches for the tail stock, tool post, and carriage lock. There may have been more, but I haven't gotten to the point of finding out yet. That will come tomorrow, I guess.

Is there a reasonably priced collet closer available for the L00 spindle?

Does the L00 use the same proprietary size centers as the 2 1/4-8? I will also be looking for a face plate, and any other tooling that I might need in L00 size.

One final question for now. Since the L taper spindle uses a key, is it safer to use in reverse than the threaded nose type? I might never do it, but I would like to know "just in case".

I would appreciate any comments from all you knowledgeable people. I am just beginning on my learning curve, and I know I have a world of things to learn. I am sure that I will have lots of questions. Thanks in advance for your patience.

Jim

Well, I finally took the plunge and bought a lathe (my first other than a mini-lathe). I just finished getting it into my shop, and it needs a good cleanup, as well as more familiarization on my part, but that will come with time

.

.I bought this lathe on very short notice, and I HOPE that I didn't go too far into the deep end without a lifeguard. I actually didn't even know the model number and serial number until I unloaded it today

, only that it was a 10L. The model number turned out to be CLK 8187 AB, and the serial number is 15990RKK 16. Am I to assume this was a "toolroom" lathe from the first 8 in the model number? Also, I assume that it was made around 1966?

, only that it was a 10L. The model number turned out to be CLK 8187 AB, and the serial number is 15990RKK 16. Am I to assume this was a "toolroom" lathe from the first 8 in the model number? Also, I assume that it was made around 1966?The ways aren't bad, but there is an area where the tailstock caused a slight bit of extra wear in the central area of the way, and it shows as a line with the original finish below, but worn smooth above. There are a few small dings, but nothing that is too noticeable (seems not to be raised much if any, compared to the surrounding surface, but I will find out more tomorrow).

I got a pleasant surprise when I discovered that it had a taper attachment that the seller had not mentioned (the original photos did not show that area, and were pretty blurry in any case). The seller also did not mention the type spindle, but I assumed that it was a L taper from the photos, and it proved to be. I think it is an L00 from the 3 3/4" thread diameter, is this correct?

It also had an almost new Bison 3-jaw chuck, as well as the original 3-jaw. I am now in the market for a 4-jaw.

Another nice extra was a telescoping steady rest (but no follow rest).

I also got another surprise that I had not expected when looking at the motor. The seller had stated that it was a single phase, two speed motor, but the plate says 3 phase. Not being knowledgeable on things electrical, is it possible that it could have been re-wired for single phase? If not, I guess I will be in the market for a phase converter. If it helps in determining whether it is three phase, the plug is a four prong rather than a three prong (see, I told you I was electrically challenged).

It also appears that some tooling got lost in shipment, like wrenches for the tail stock, tool post, and carriage lock. There may have been more, but I haven't gotten to the point of finding out yet. That will come tomorrow, I guess.

Is there a reasonably priced collet closer available for the L00 spindle?

Does the L00 use the same proprietary size centers as the 2 1/4-8? I will also be looking for a face plate, and any other tooling that I might need in L00 size.

One final question for now. Since the L taper spindle uses a key, is it safer to use in reverse than the threaded nose type? I might never do it, but I would like to know "just in case".

I would appreciate any comments from all you knowledgeable people. I am just beginning on my learning curve, and I know I have a world of things to learn. I am sure that I will have lots of questions. Thanks in advance for your patience.

Jim