Hello forum

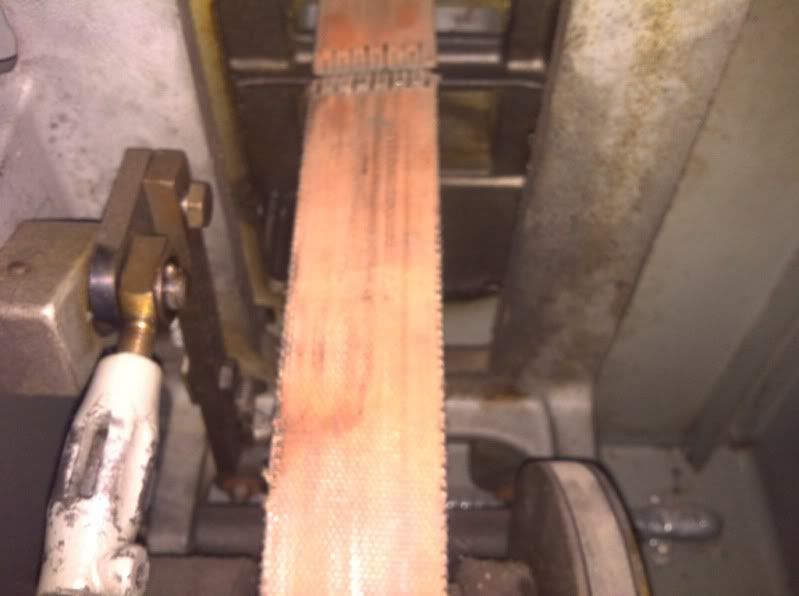

So I embarked on the journey of getting a lathe at home. Been in the machining world for 6 years now, and decided it was time. Used a 9 inch southbend at my brothers work and loved it. So I started searching, nothing months pass by I pick up a Atl... What a horrible machine! Sold it without ever doing any work on it. Was trying to get a bigger 14x40 gear head but in the process I came accross this beauty.

From what I've read it's a 10k with variable speed so here are my questions, I know the answers are in here somewhere maybe but the amount if info in this site is overwhelming.

First backlash, I know a machine of this age is going to have some on my compound I have 10 thou I think that's how the increments are on it which is not bad for me

The cros slide, 60 thou. Not good that machine is super accurate even though its not level yet I was taking off .001 on demand. Almost like my hardinge at work. Do I need a new nut for the cross slide?

Second the threading dial won't stay engaged, I tighten the grub screw to keep it engaged and the thing just pops out, do I need a new dowel on which the dial is mounted to?

Third the motor it has, I know originally it was three phase, now it has a 1/2 hp 110v single phase Baldor in it. What motor can I replace it with? I don't see a need for three phase since I already have the variable speed. What hp rating is adequate it best for it? I'm thinking a 1 1/2 hp 220 v single phase will provide better power and a lower amp draw. I am cutting mostly 303 ss on it and it seems to handle I pretty well as long as I skiny take more than .020 off.

I need to get me a quick change tool post ASAP, that rocker post is a pita.

Beautiful machine that I need to get into work mode ASAP as I have lots of customers waiting for my product.

Oh yeah need to order leveling feet so I can get her off the ground, it sits waaay to low.

Comments and input is greatly appreciated.

URQ

So I embarked on the journey of getting a lathe at home. Been in the machining world for 6 years now, and decided it was time. Used a 9 inch southbend at my brothers work and loved it. So I started searching, nothing months pass by I pick up a Atl... What a horrible machine! Sold it without ever doing any work on it. Was trying to get a bigger 14x40 gear head but in the process I came accross this beauty.

From what I've read it's a 10k with variable speed so here are my questions, I know the answers are in here somewhere maybe but the amount if info in this site is overwhelming.

First backlash, I know a machine of this age is going to have some on my compound I have 10 thou I think that's how the increments are on it which is not bad for me

The cros slide, 60 thou. Not good that machine is super accurate even though its not level yet I was taking off .001 on demand. Almost like my hardinge at work. Do I need a new nut for the cross slide?

Second the threading dial won't stay engaged, I tighten the grub screw to keep it engaged and the thing just pops out, do I need a new dowel on which the dial is mounted to?

Third the motor it has, I know originally it was three phase, now it has a 1/2 hp 110v single phase Baldor in it. What motor can I replace it with? I don't see a need for three phase since I already have the variable speed. What hp rating is adequate it best for it? I'm thinking a 1 1/2 hp 220 v single phase will provide better power and a lower amp draw. I am cutting mostly 303 ss on it and it seems to handle I pretty well as long as I skiny take more than .020 off.

I need to get me a quick change tool post ASAP, that rocker post is a pita.

Beautiful machine that I need to get into work mode ASAP as I have lots of customers waiting for my product.

Oh yeah need to order leveling feet so I can get her off the ground, it sits waaay to low.

Comments and input is greatly appreciated.

URQ