I picked up a new Infrared lamp to force dry my paint, it being a little cool in the shop.

I thought you all might want to see, it is an American made product by Infratech.

http://www.wswells.com/photos/1968-10L-swells/1.JPG

http://www.wswells.com/photos/1968-10L-swells/2.JPG

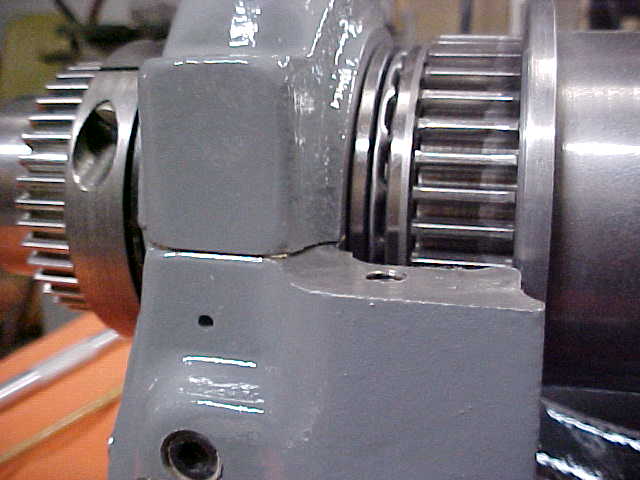

Long story shortened, I picked up a 1968 10L(in the back ground) that had been turning wood for 10 years and to my horror after paying for it, was told it had always just been oiled with automotive gear lube in the headstock. I could not bring myself to run it like that,

and besides it really had a bad smell to it with that gear oil in it. Well I just had to see for

myself just how bad it was....and if all those stories are true you hear about saw dust and wood chips.

http://www.wswells.com/photos/1968-10L-swells/3.JPG

http://www.wswells.com/photos/1968-10L-swells/4.JPG

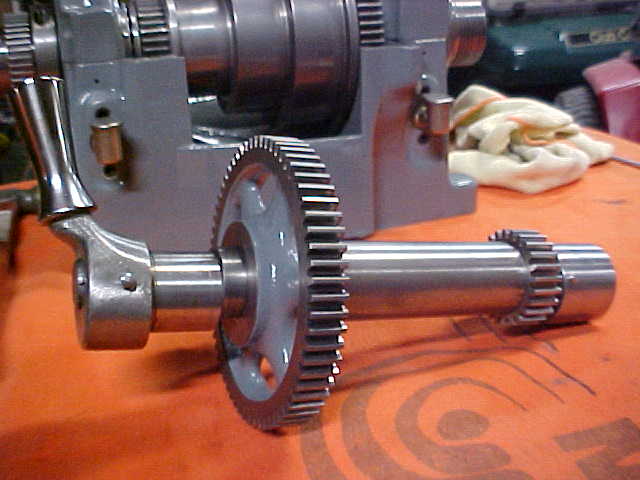

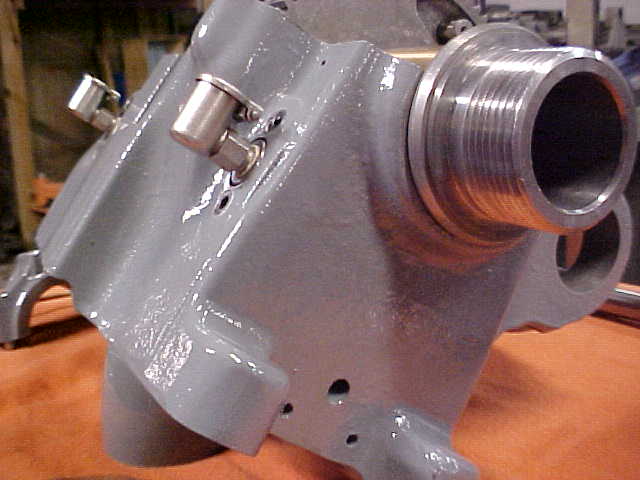

After pulling the spindle, hard to believe everything was perfect, not a score one.

The spindle capillary oilers were a bit dirty:

http://www.wswells.com/photos/1968-10L-swells/13a.JPG

I ordered a new set from Ted along with the gits oilers and could not stop myself from

cleaning and painting the headstock.

Cleaned and taped, Infrared on, Major Tom:

http://www.wswells.com/photos/1968-10L-swells/5.JPG

http://www.wswells.com/photos/1968-10L-swells/6.JPG

Her's a few shots of proper installation of the oilers, after spindle is removed.

Enjoy:

Install the lower pipe plugs to contain the small amount of oil you are about to add:

http://www.wswells.com/photos/1968-10L-swells/7.JPG

http://www.wswells.com/photos/1968-10L-swells/8.JPG

http://www.wswells.com/photos/1968-10L-swells/9.JPG

http://www.wswells.com/photos/1968-10L-swells/10.JPG

http://www.wswells.com/photos/1968-10L-swells/11.JPG

Soak your wicks in...number 10, get your wires ready...

http://www.wswells.com/photos/1968-10L-swells/12.JPG

http://www.wswells.com/photos/1968-10L-swells/13.JPG

A few shots down the hole, can you hear me ground control...

http://www.wswells.com/photos/1968-10L-swells/14.JPG

Brush it around, up and down, Major Tom.

http://www.wswells.com/photos/1968-10L-swells/15.JPG

http://www.wswells.com/photos/1968-10L-swells/15a.JPG

These are paint gun cleaning wires, perfect:

http://www.wswells.com/photos/1968-10L-swells/16.JPG

Wires ready, engines on...

http://www.wswells.com/photos/1968-10L-swells/17.JPG

contacts down , wires in...ignition on at 10...

http://www.wswells.com/photos/1968-10L-swells/18.JPG

http://www.wswells.com/photos/1968-10L-swells/19.JPG

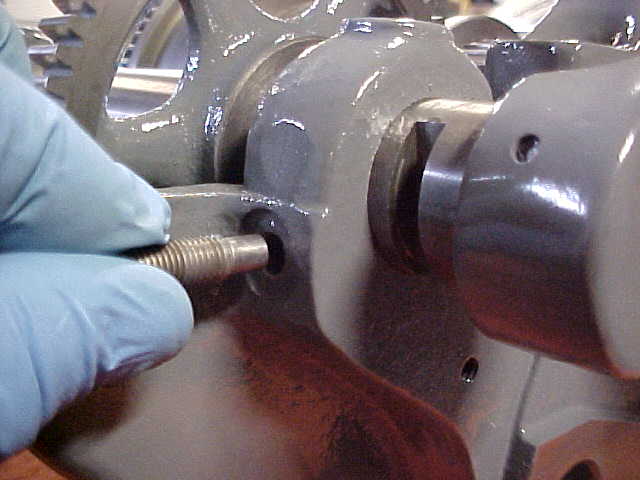

The spindle is clean and set in, and we pull the wires and have lift off.

http://www.wswells.com/photos/1968-10L-swells/20.JPG

I'll take a few more photos as I clean and get it ready to run.

Steve

I thought you all might want to see, it is an American made product by Infratech.

http://www.wswells.com/photos/1968-10L-swells/1.JPG

http://www.wswells.com/photos/1968-10L-swells/2.JPG

Long story shortened, I picked up a 1968 10L(in the back ground) that had been turning wood for 10 years and to my horror after paying for it, was told it had always just been oiled with automotive gear lube in the headstock. I could not bring myself to run it like that,

and besides it really had a bad smell to it with that gear oil in it. Well I just had to see for

myself just how bad it was....and if all those stories are true you hear about saw dust and wood chips.

http://www.wswells.com/photos/1968-10L-swells/3.JPG

http://www.wswells.com/photos/1968-10L-swells/4.JPG

After pulling the spindle, hard to believe everything was perfect, not a score one.

The spindle capillary oilers were a bit dirty:

http://www.wswells.com/photos/1968-10L-swells/13a.JPG

I ordered a new set from Ted along with the gits oilers and could not stop myself from

cleaning and painting the headstock.

Cleaned and taped, Infrared on, Major Tom:

http://www.wswells.com/photos/1968-10L-swells/5.JPG

http://www.wswells.com/photos/1968-10L-swells/6.JPG

Her's a few shots of proper installation of the oilers, after spindle is removed.

Enjoy:

Install the lower pipe plugs to contain the small amount of oil you are about to add:

http://www.wswells.com/photos/1968-10L-swells/7.JPG

http://www.wswells.com/photos/1968-10L-swells/8.JPG

http://www.wswells.com/photos/1968-10L-swells/9.JPG

http://www.wswells.com/photos/1968-10L-swells/10.JPG

http://www.wswells.com/photos/1968-10L-swells/11.JPG

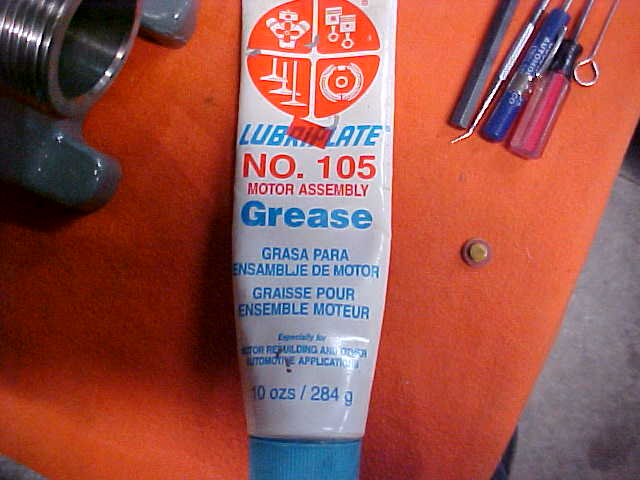

Soak your wicks in...number 10, get your wires ready...

http://www.wswells.com/photos/1968-10L-swells/12.JPG

http://www.wswells.com/photos/1968-10L-swells/13.JPG

A few shots down the hole, can you hear me ground control...

http://www.wswells.com/photos/1968-10L-swells/14.JPG

Brush it around, up and down, Major Tom.

http://www.wswells.com/photos/1968-10L-swells/15.JPG

http://www.wswells.com/photos/1968-10L-swells/15a.JPG

These are paint gun cleaning wires, perfect:

http://www.wswells.com/photos/1968-10L-swells/16.JPG

Wires ready, engines on...

http://www.wswells.com/photos/1968-10L-swells/17.JPG

contacts down , wires in...ignition on at 10...

http://www.wswells.com/photos/1968-10L-swells/18.JPG

http://www.wswells.com/photos/1968-10L-swells/19.JPG

The spindle is clean and set in, and we pull the wires and have lift off.

http://www.wswells.com/photos/1968-10L-swells/20.JPG

I'll take a few more photos as I clean and get it ready to run.

Steve

. I'll show you on the covers...I really like the infrared heater, the

. I'll show you on the covers...I really like the infrared heater, the