Hi everyone,

Just bought my first lathe, South Bend 9.

Thought this would be a good place to ask questions and chat.

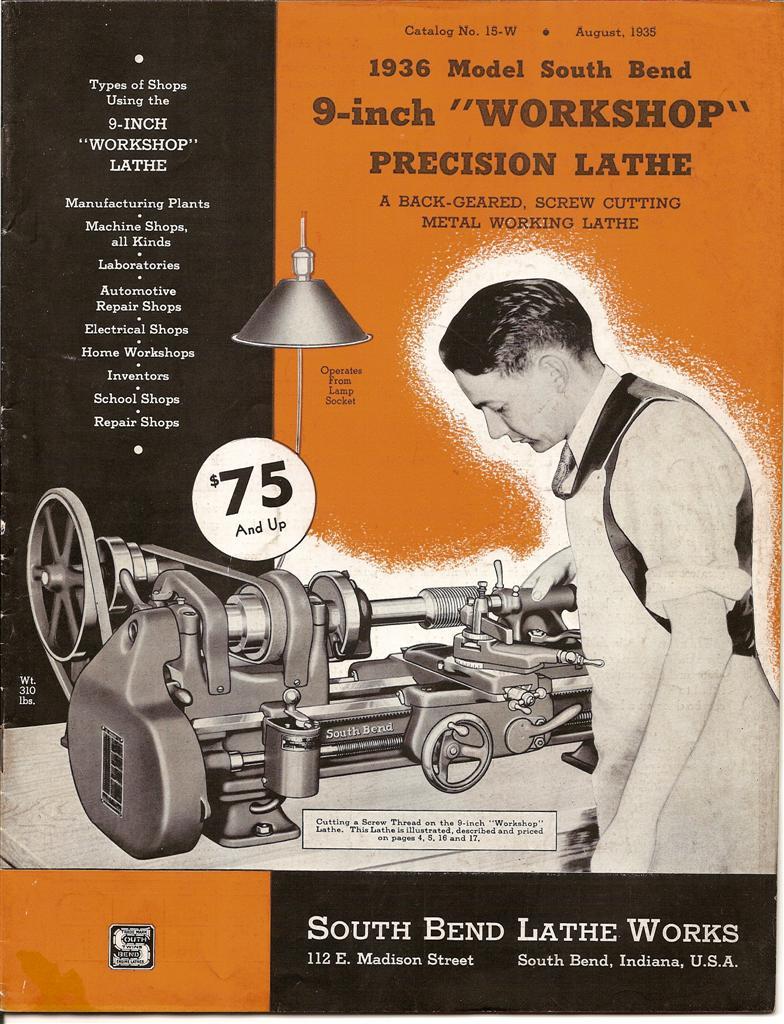

Serial number is 66683, 1936???

Does this "horizontal drive unit" (piece that the electric motor bolts to) look correct?

I have been searching the web for pictures of this unit and cant seem to find one like it.

Just bought my first lathe, South Bend 9.

Thought this would be a good place to ask questions and chat.

Serial number is 66683, 1936???

Does this "horizontal drive unit" (piece that the electric motor bolts to) look correct?

I have been searching the web for pictures of this unit and cant seem to find one like it.